Modified concrete and preparation method thereof

A concrete and concrete foundation technology, applied in the field of concrete, can solve the problems of damaging the volume stability of concrete, reducing the durability of concrete, and shortening the service life, so as to improve compactness and bonding, good crack resistance and crack resistance, and reduce total The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

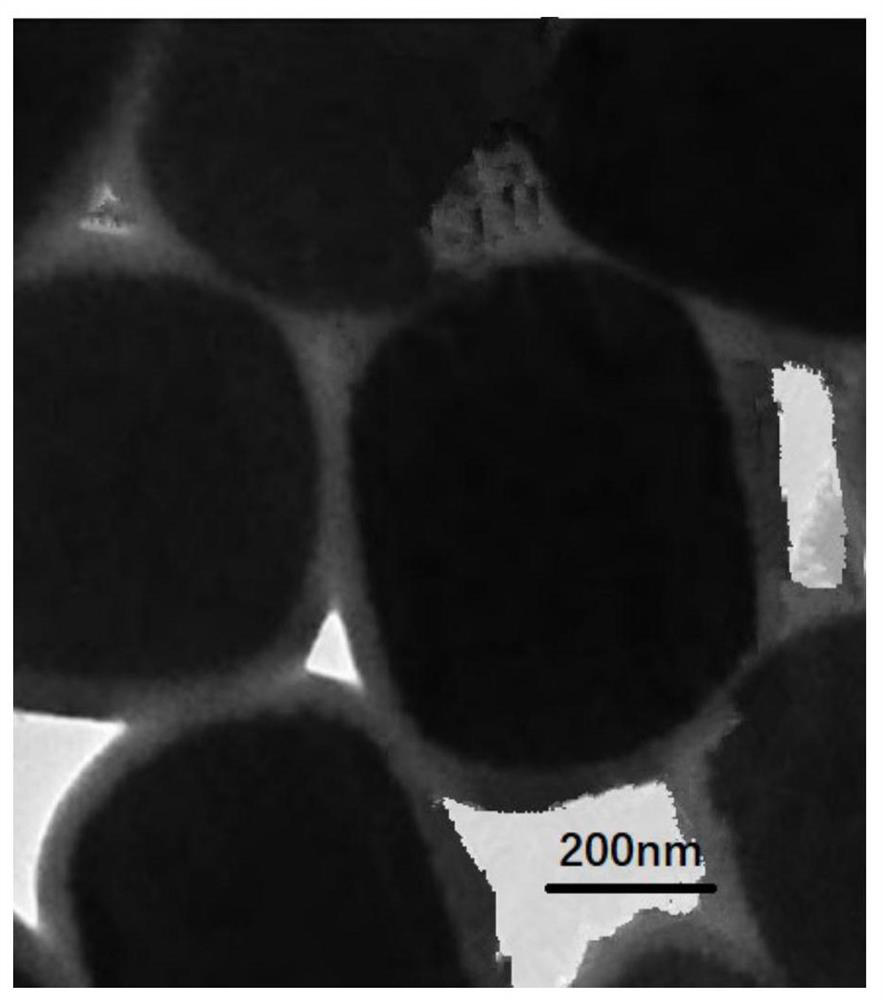

Image

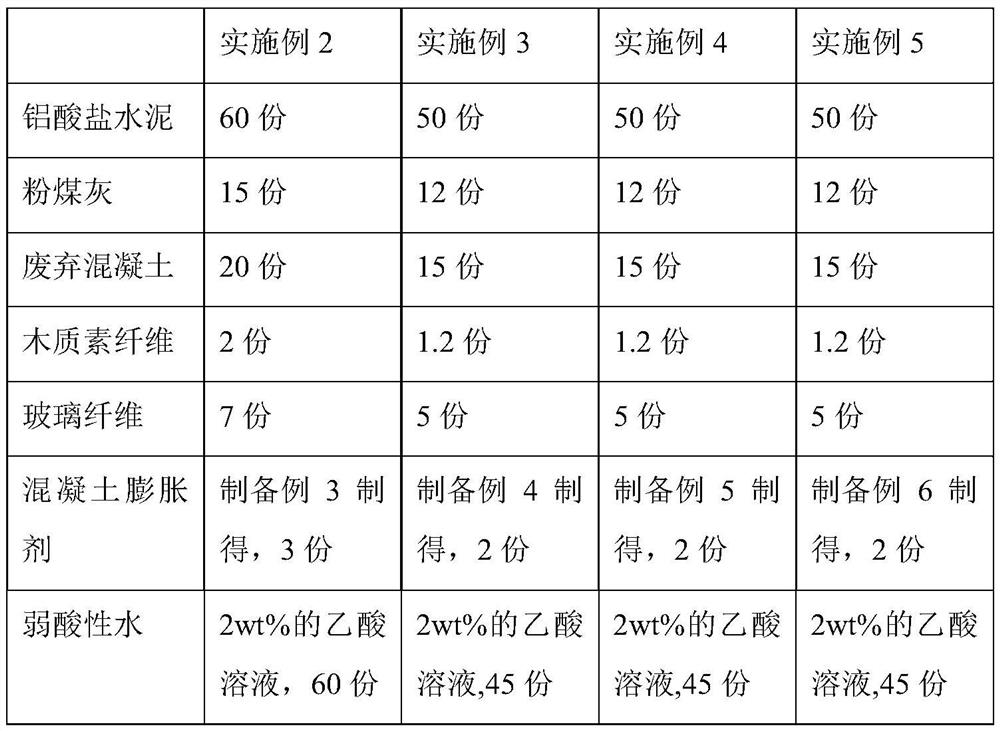

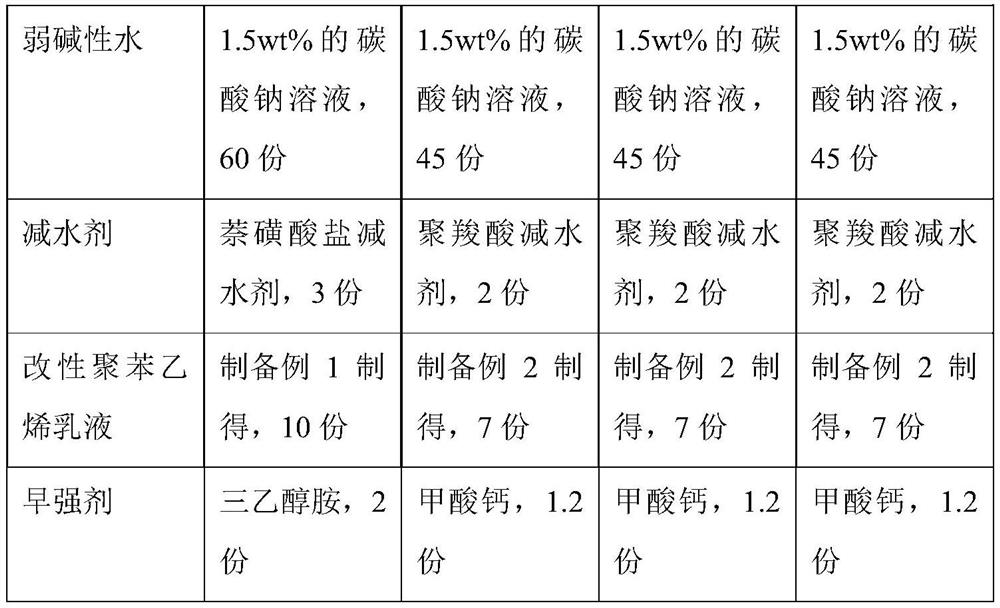

Examples

preparation example 1

[0043] The preparation of preparation example 1 modified polystyrene emulsion

[0044] Prepared by:

[0045] S1. Pre-irradiation: 100g polystyrene emulsion is irradiated; the irradiation treatment is irradiated under a Co-60 lamp for 3s, and the absorbed dose is 40kGy;

[0046] S2. Free radical polymerization: Add 5g of silane coupling agent KH570 to 100g of pre-irradiated polystyrene emulsion, under nitrogen, add 0.5g of initiator to carry out heating polymerization reaction to obtain silane coupling agent graft modified polystyrene Styrene emulsion.

[0047] The initiator consists of ammonium persulfate and potassium bisulfite with a mass ratio of 4:1.

preparation example 2

[0048] The preparation of preparation example 2 modified polystyrene emulsions

[0049] Prepared by:

[0050] S1. Pre-irradiation: 100g polystyrene emulsion is irradiated; the irradiation treatment is irradiated under a Co-60 lamp for 7s, and the absorbed dose is 60kGy;

[0051] S2. Free radical polymerization: Add 10g of silane coupling agent KH570 to 100g of pre-irradiated polystyrene emulsion, under nitrogen, add 0.5g of initiator to carry out heating polymerization reaction to obtain silane coupling agent graft modified polystyrene Styrene emulsion.

[0052] The initiator is composed of potassium persulfate and sodium hypophosphite with a mass ratio of 7:1.

preparation example 3

[0053] The preparation of preparation example 3 concrete expansive agent

[0054] Concrete expansion agent raw material composition: 7 parts of calcium oxide, 10 parts of magnesium oxide, 2 parts of sodium lignosulfonate, 15 parts of sodium alginate, 7 parts of calcium chloride and 1.5 parts of sodium tripolyphosphate.

[0055] Concrete expansion agent preparation includes the following steps:

[0056] S1. Grind sodium tripolyphosphate to 150 mesh, add calcium oxide and magnesium oxide, ball mill for 2 hours, and mix well;

[0057] S2. Add the mixture obtained in step S1 into water, after ultrasonic dispersion is uniform, add sodium lignosulfonate and sodium alginate, stir and dissolve, increase the stirring speed and stir for 0.5h, then add calcium chloride solution dropwise, and keep the stirring speed No change, after 0.5h of reaction, stop stirring, filter to obtain concrete expansion agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com