A kind of max phase multilayer composite coating and its preparation method and application

A multi-layer composite and coating technology, which is applied in coatings, metal material coating processes, electrochemical generators, etc., can solve the problems of reduced corrosion resistance of MAX phase coatings, and achieve excellent corrosion resistance and excellent electrical conductivity , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

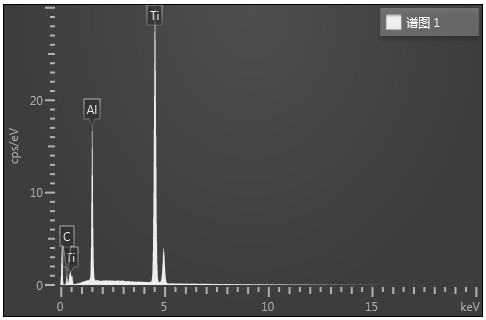

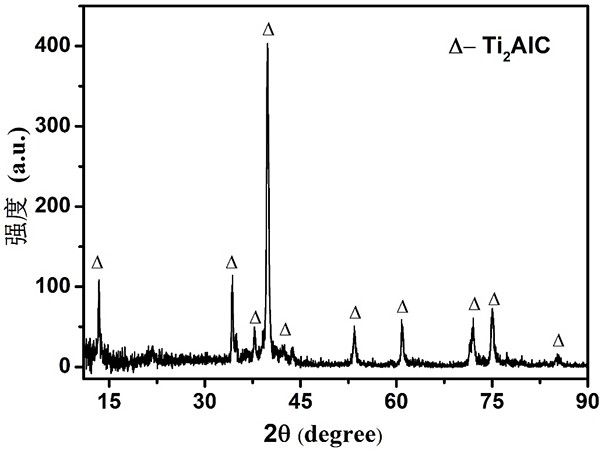

[0029] One aspect of the embodiments of the present invention provides a method for preparing a MAX phase multilayer composite coating, which includes:

[0030] Using high-power pulse magnetron sputtering technology, using Ti target as target material, CH 4 As a working gas, deposit and form Ti on the surface of the substrate 2 C precursor layer;

[0031] Using high-power pulse magnetron co-sputtering technology, using Ti target and Al target as target materials, CH 4 For the working gas, the Ti 2 Deposition on the surface of C precursor layer to form Ti 2 AlC precursor layer;

[0032] and, for deposition with the Ti 2 C precursor layer and Ti 2 The substrate of the AlC precursor layer is vacuum annealed to form Ti on the surface of the substrate 2 C transition layer and Ti 2 AlC layer, that is, to obtain the MAX phase multilayer composite coating (also denoted as Ti 2 AlCMAX phase multilayer composite coating).

[0033] In some more specific embodiments, the prepara...

Embodiment 1

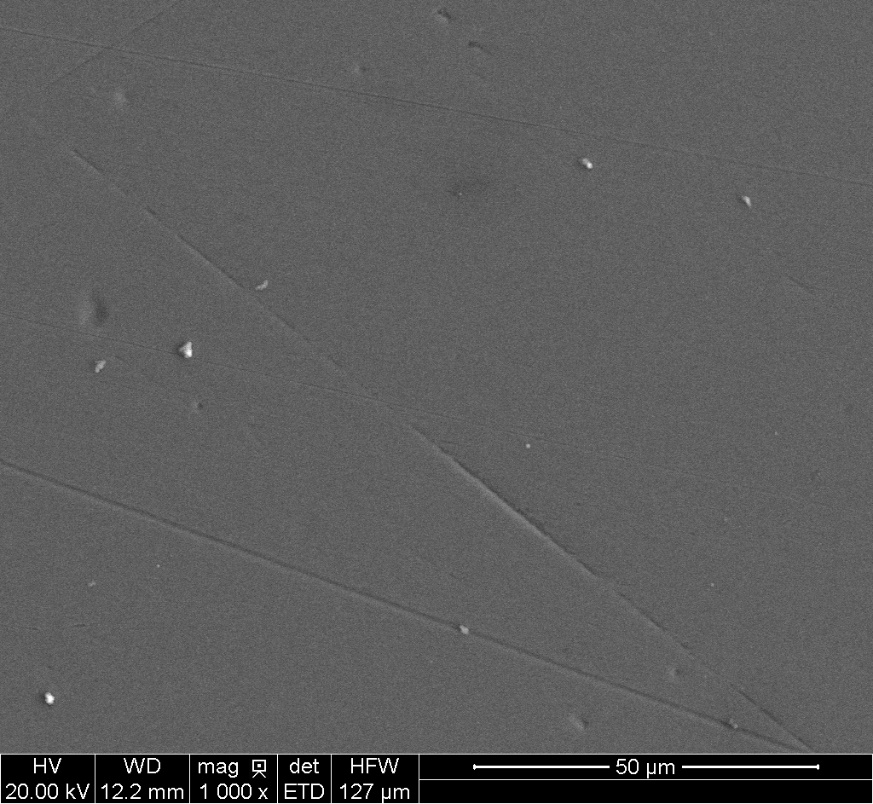

[0067] In this embodiment, the substrate is a 316L stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the preparation method of the MAX phase multilayer composite coating on the surface of the substrate is as follows:

[0068] (1) Put the substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Pa, feed 60 ml / min of argon gas into the vacuum chamber, set the linear anode ion source current to 0.5 A, the substrate bias to -60V, and use ionized argon ions to etch the substrate for 30 minutes;

[0069] (2) The Ti-C layer was deposited by single-target high-power pulse magnetron sputtering technology, the substrate bias was -180 V, the high-power pulse duty cycle was 4.5%, the high-power pulse frequency was 900 Hz, and the pulse width was 400 μs, the average sputtering power of the Ti target is 1000 W, and the reaction gas CH 4 The flow rate was 2 sccm, the target distance bet...

Embodiment 2

[0082] In this embodiment, the substrate is a titanium alloy used for proton exchange membrane fuel cells, and the preparation method of the MAX phase multilayer composite coating on the surface of the substrate is as follows:

[0083] (1) Put the substrate after cleaning, degreasing and drying into the cavity, and wait until the vacuum pressure in the cavity is 3.0×10 -5 Below Pa, flow 60 ml / min of argon gas into the vacuum chamber, set the linear anode ion source current to 0.5 A, substrate bias to -60V, and use ionized argon ions to etch the substrate for 30 min;

[0084] (2) The Ti-C layer was deposited by single-target high-power pulsed magnetron sputtering technology, the substrate bias was -200 V, the high-power pulse duty cycle was 5%, the high-power pulse frequency was 1000 Hz, and the pulse width was 500 μs, the average sputtering power of the Ti target is 1000W, the reaction gas CH 4 The flow rate was 2 sccm, the target distance between the substrate and the Ti tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com