Triangular nano array assembled by iron-doped cobalt sulfide and molybdenum sulfide nanosheets as well as preparation method and application of triangular nano array

A nano-array and cobalt sulfide technology, applied in the field of triangular nano-array and its preparation, can solve the problems of lack of practicability, difficulty in taking into account high catalytic activity and electrochemical stability, and achieve improved HER catalytic activity, excellent HER catalytic activity, increased The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The second aspect of the present application provides a method for preparing the triangular nanoarray assembled with iron-doped cobalt sulfide and molybdenum sulfide nanosheets provided in the first aspect of the present application, which includes the following steps:

[0026] (1) Mix 0.025-0.075mol / L divalent cobalt salt aqueous solution with 0.3-0.5mol / L 2-methylimidazole aqueous solution at a volume ratio of 1:2-2:1, immerse the carbon cloth in it, and statically Leave it for 2-6 hours to get CC@Co-MOF;

[0027] Among them, the CC@Co-MOF represents a Co metal-organic framework compound grown on a carbon cloth base. The inventors found in the research that the CC@Co-MOF has a controllable size and uniform element distribution, which is an ideal precursors. Co-MOF is grown on the carbon cloth substrate in the form of triangular nanowalls, forming triangular nanoarrays.

[0028] (2) Immerse the CC@Co-MOF in 10-20 mg / mL of K 4 [Fe(CN) 6 ] in aqueous solution, let it...

preparation example 1C

[0038] Preparation Example 1CC@Fe-CoS 2 @MoS 2 Synthesis

[0039] 1) Carbon cloth pretreatment

[0040] Cut 2×3cm 2 The carbon cloth was ultrasonically cleaned with concentrated nitric acid, acetone, ethanol and deionized water for 30 min to remove surface impurities.

[0041] 2) Synthesis of CC@Co-MOF

[0042] 0.582g(2mmol)Co(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL of deionized water, and 0.05 mol / L cobalt nitrate aqueous solution was obtained after ultrasonication for 10 min. 1.313g of 2-methylimidazole was dissolved in 40mL of deionized water, and 0.4mol / L 2-methylimidazole aqueous solution was obtained after ultrasonication for 10min. After mixing the above two solutions, quickly add a piece of 2×3cm 2 The carbon cloth was taken out after standing for 4 hours, and the product was washed with deionized water and dried in vacuum to obtain the Co-MOF grown on the carbon cloth, which was denoted as CC@Co-MOF.

[0043] 3) Synthesis of CC@CoFe PBA

[0044] Immerse CC@...

Embodiment 1X

[0055] Embodiment 1 X-ray diffraction (XRD) analysis:

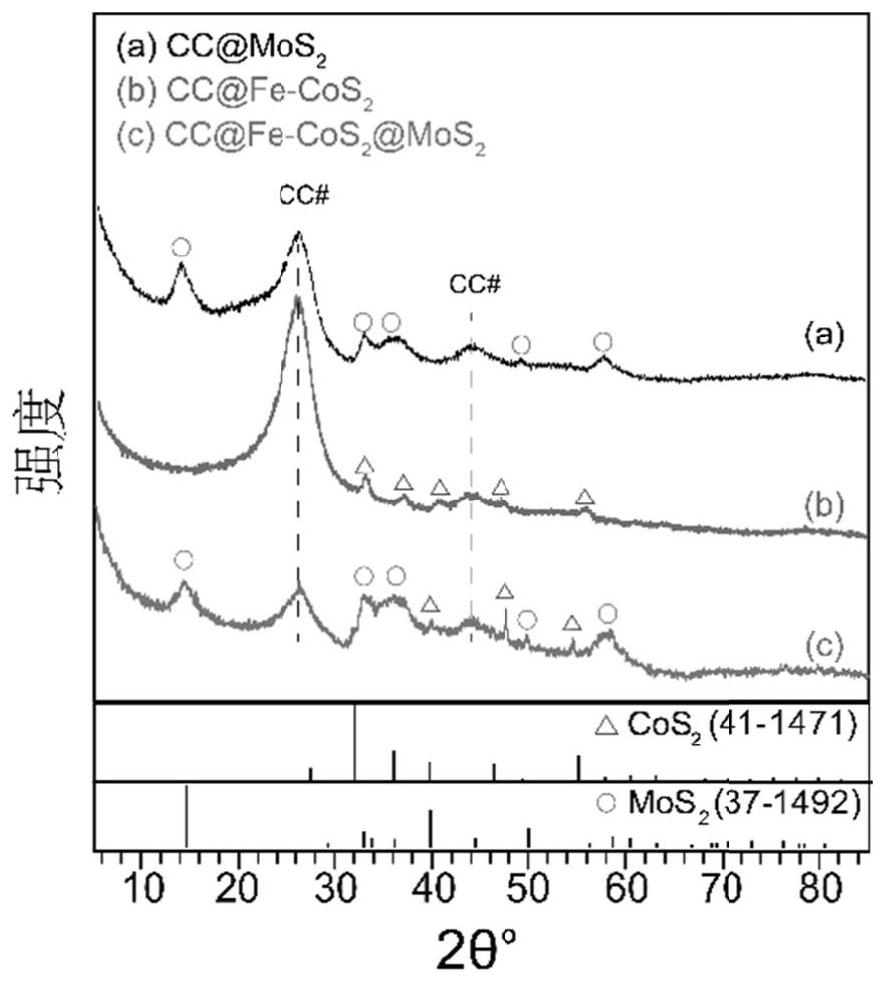

[0056] For the intermediate CC@Fe-CoS of Preparation Example 1 2、 Final product CC@Fe-CoS 2 @MoS 2 and CC@MoS of Comparative Example 1 2 Carry out XRD analysis, gained XRD pattern is as follows figure 1 shown. Among them, (a) is CC@MoS 2 ; (b) is CC@Fe-CoS 2 ; (c) is CC@Fe-CoS 2 @MoS 2 . As can be seen from the figure, CC@Fe-CoS 2 (b) Diffraction peaks appear at 32.9°, 36.9°, 40.8°, 47.1° and 55.9°, corresponding to CoS 2 (PDF card number 41-1471, identified by the symbol "Δ") (200), (210), (211), (220) and (311) crystal planes. with CoS 2 Compared with the standard card (the corresponding diffraction peak positions are 32.4°, 36.3°, 40.0°, 46.4°, 55.0°), the peak positions are slightly shifted to the right, corresponding to the decrease of the interplanar distance, indicating that Fe with a small radius 2+ (ionic radius of 0.061nm) partially replaces Co with a larger radius 2+ (radius 0.065nm), lattice dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com