Livestock and poultry manure anaerobic fermentation biogas residue biomass charcoal as well as preparation method and application thereof

A technology for anaerobic fermentation and livestock and poultry manure, applied in chemical instruments and methods, vaporization of by-products, and other chemical processes, can solve the problems of increased preparation costs and complicated preparation methods, and achieve low preparation costs and simple synthetic routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A synthetic route of cow dung biogas residue biochar, comprising the following steps:

[0033] (1) Dry the collected cow dung biogas residue at 60°C for 12 hours, and mechanically crush it into powder for later use;

[0034] (2) Take 4 parts of the powder obtained in step (1) and place them in the crucibles of samples labeled 1#-4# respectively. Take the 1# sample and put it in a muffle furnace at 500°C, and put the 2# sample into a muffle furnace at 600°C. In the Furnace, the 3# sample was placed in a 700°C muffle furnace, the 4# sample was placed in a 800°C muffle furnace, the heating rate of the muffle furnace was 10°C / min, and the 1#-4# samples were heated separately. solution for 2 hours;

[0035] (3) grinding the sample after step (2) pyrolysis into black powder after cooling down;

[0036] (4) Wash the sample obtained in step (3) repeatedly with distilled water to remove impurities therein and ensure that the solution pH=7;

[0037] (5) drying the sample obtai...

Embodiment 2

[0042] The biogas residue biochar prepared in Example 1 was used as the adsorbent of BPA. The experimental steps are as follows:

[0043] (1) Use a 100mL beaker as a reactor, add 50mL of 10mg / L BPA wastewater, and number 1#-4# reactors respectively.

[0044] In 1# reactor, add 1# sample in 10mg embodiment 1;

[0045] In 2# reactor, add 2# sample in 10mg embodiment 1;

[0046] In 3# reactor, add 3# sample in 10mg embodiment 1;

[0047] In 4# reactor, add 4# sample in 10mg embodiment 1.

[0048] Magnetic stirring (150 rpm) was performed respectively, and samples were taken at preset time intervals.

[0049] The concentration of remaining BPA was detected by high performance liquid chromatography, and the adsorption kinetic curve was drawn.

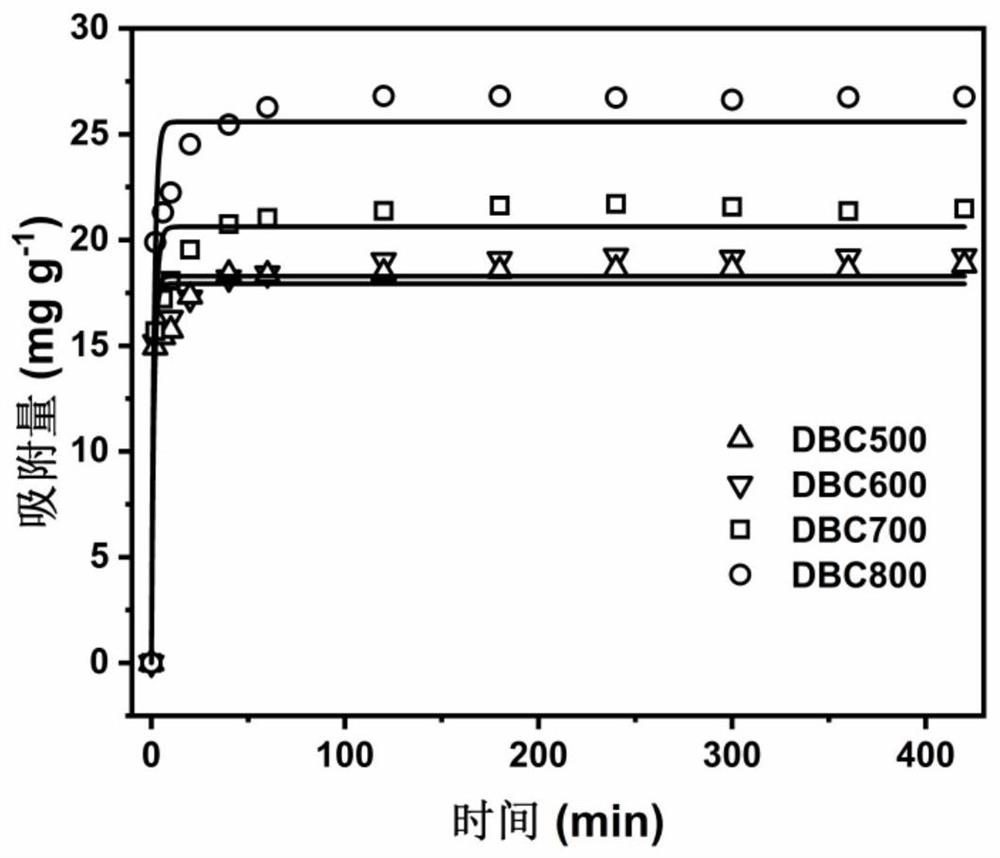

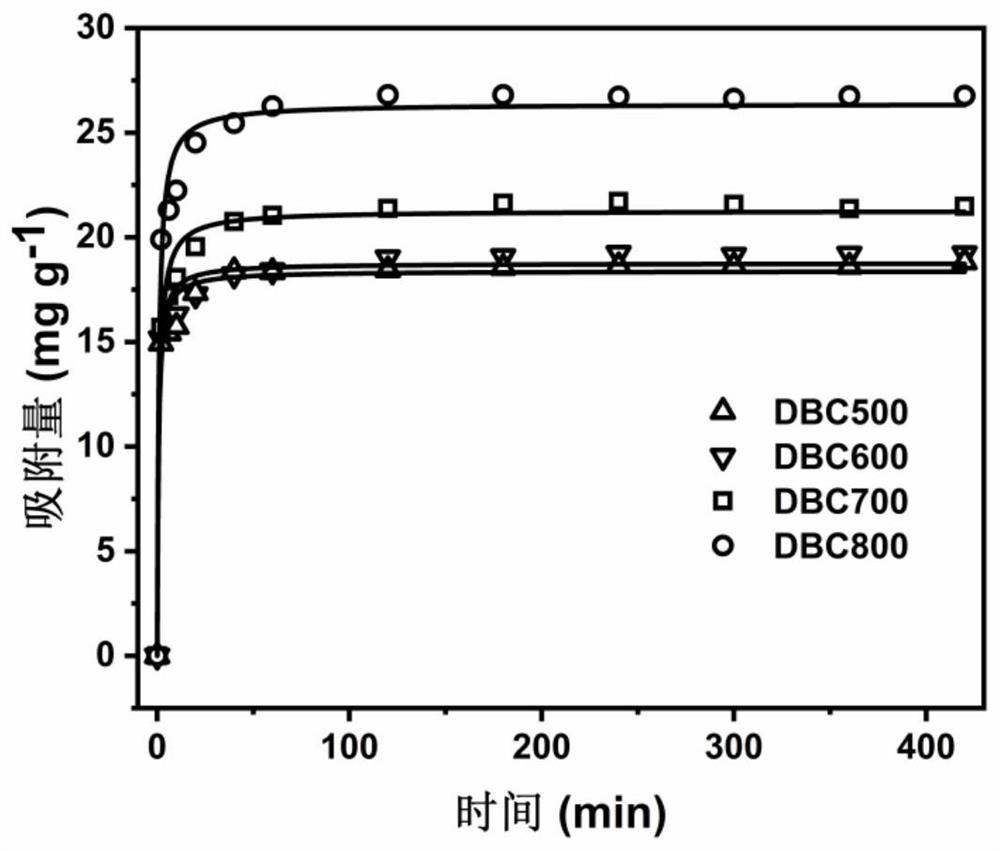

[0050] The biogas residue biochar prepared at different temperatures in Example 1 is to BPA adsorption kinetics result as follows figure 1 and figure 2 shown. Depend on figure 1 and figure 2 It can be seen that the adsorption capac...

Embodiment 3

[0052] The experimental steps and conditions are similar to those in Example 2. After the BPA adsorption reaches equilibrium, add 5mM of H to 1#-4# reactors respectively 2 o 2 , stirred and sampled.

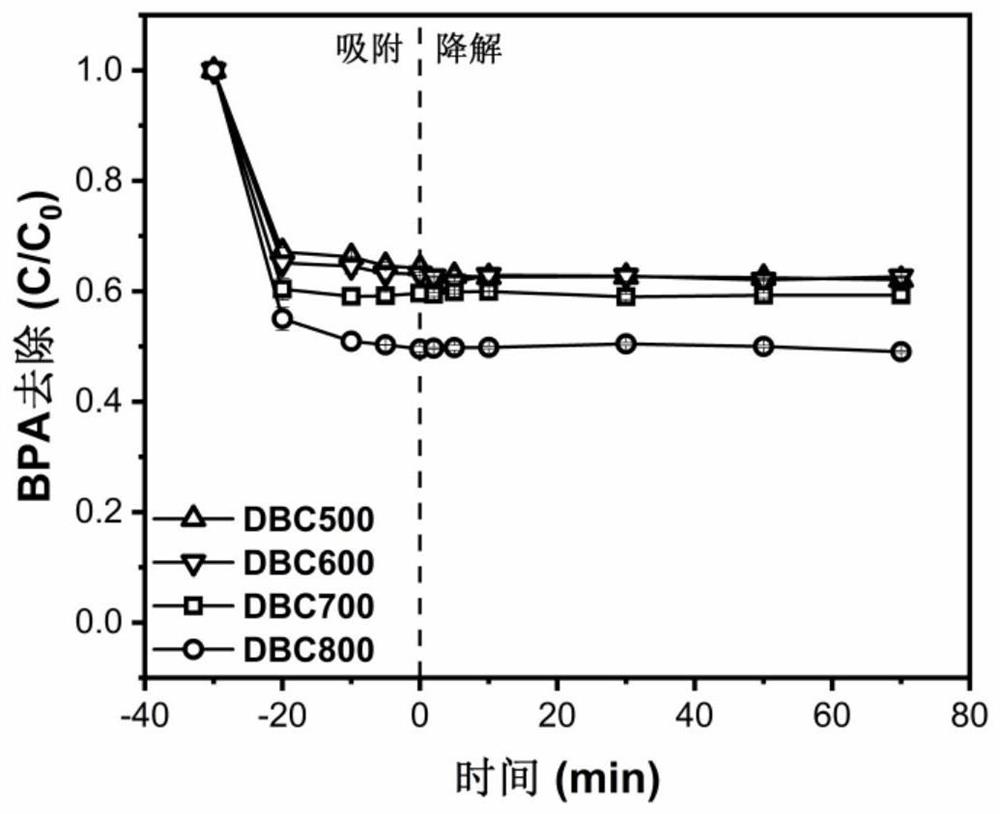

[0053] Biogas residue biochar prepared at different temperatures in Example 1 activates H 2 o 2 The effect of degrading BPA-containing wastewater is as follows: image 3 shown. Such as image 3 As shown, the effect of biochar from biogas residue on H 2 o 2 The activation ability is weak. It is worth noting that biochar from biogas residues prepared at different pyrolysis temperatures activated H 2 o 2 The effect is different. Among them, DBC800 for H 2 o 2 has the strongest activation ability. It can be seen from the figure that DBC800 has the best removal effect on BPA, so follow-up research mainly focuses on DBC800.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com