Method for preparing cryptographic primitive based on perovskite crystal and application thereof

A perovskite and crystal technology, applied in the field of cryptographic communication, can solve the problems of low authentication throughput, low efficiency, and high cost of cryptographic primitives, achieving the effects of more pixels, efficient programming and authentication, and strong randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

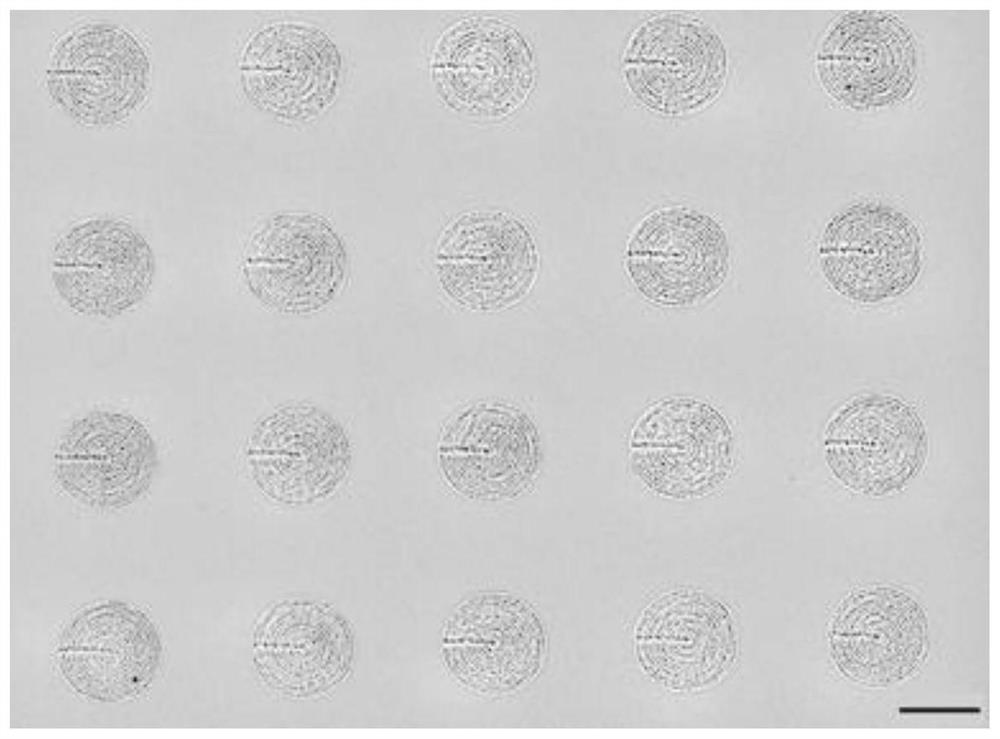

[0040] Example 1: Verification of the randomness of crystal morphology produced during the evaporation of precursor droplets

[0041] Step 1. Prepare the liquid-repellent substrate

[0042] Perform plasma cleaning on the surface of the silicon wafer substrate, then put 3 μl of perfluorooctyltriethoxysilane in an open vial, and then put it in a closed box with the substrate, and then place the box at 120 °C In the oven for 2 hours, vapor-deposit perfluorooctyltriethoxysilane on the surface of the substrate to modify the surface of the substrate to form a hydrophobic surface. Hydrophilic patterned arrays (such as figure 1 shown), then place it in ethanol for ultrasonic cleaning for 5 minutes and then dry it for later use;

[0043] Step 2. Prepare precursor fluid

[0044] The precursor fluid is CsPbClBr 2 / DMSO, the concentration is 0.1mol / L;

[0045] Step 3. In situ observation of droplet evaporation process

[0046] Place the liquid-friendly substrate obtained in Step 1 u...

Embodiment 2

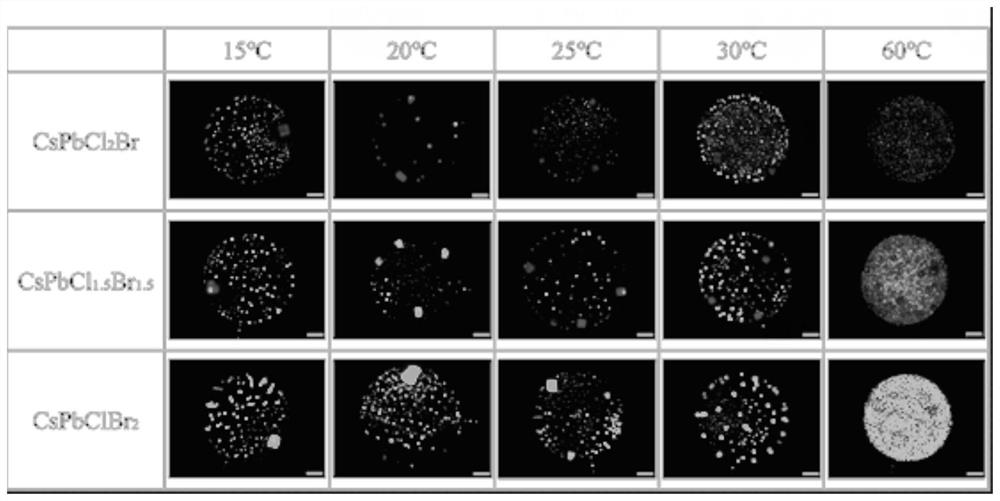

[0048] Embodiment 2 screens the most suitable evaporation temperature

[0049] Step 1. Prepare the liquid-repellent substrate

[0050] Perform plasma cleaning on the surface of the silicon wafer substrate, then put 5 μl of perfluorooctyltriethoxysilane in an open vial, and then put it in a closed box with the substrate, and then place the box in a 120°C In the oven for 2 hours, vapor-deposit perfluorooctyltriethoxysilane on the surface of the substrate to modify the surface of the substrate to form a hydrophobic surface. The hydrophilic patterned array was obtained, and then it was ultrasonically cleaned in ethanol for 5 minutes and then dried for use;

[0051] Step 2. Prepare precursor fluid

[0052] Prepare three precursor fluids with a concentration of 0.1mol / L. The preparation method is as follows:

[0053] CsPbClBr 2 / DMSO precursor fluid: take 0.1mmol PbBr 2 Dissolve in 10mL DMSO solvent, and stir magnetically at 50°C until the powder is completely dissolved. Then ...

Embodiment 3

[0062] Embodiment 3 The influence of base pattern size on perovskite crystal quantity and size

[0063] Rough hydrophilic pattern arrays with diameters of 40 μm, 60 μm, 80 μm, 100 μm, 120 μm and 140 μm were constructed on the hydrophilic and hydrophobic substrates using the same laser engraving processing parameters to construct CsPbCl 1.5 Br 1.5 Precursor droplet array to ensure other parameters are consistent, including the use of the same precursor solution, the same coating parameters, consistent substrate temperature and ambient humidity during coating, the same temperature and humidity during evaporation in a constant temperature and humidity box, and evaporation time. Finally, we fabricated perovskite crystal arrays with compositional segregation on arrays of hydrophilic-hydrophobic patterns of different sizes. We use SEM to take pictures of its microscopic appearance, and take pictures of the microscopic appearance of one hundred hydrophilic patterns for each size pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com