A kind of parabolic polyimide/silver composite film and preparation method thereof

A technology of polyimide and composite film, which is applied in textiles and papermaking, fiber treatment, fiber type, etc. It can solve the problems of high requirements for power supply equipment, high voltage, and affecting the normal operation of other equipment, and achieve excellent interface performance. Easy to form and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

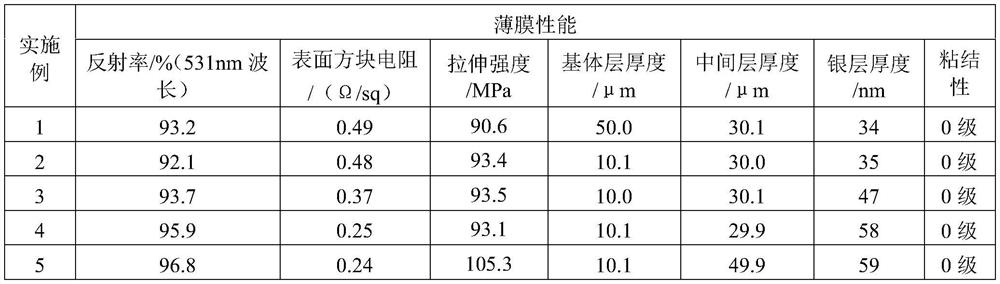

Embodiment 1

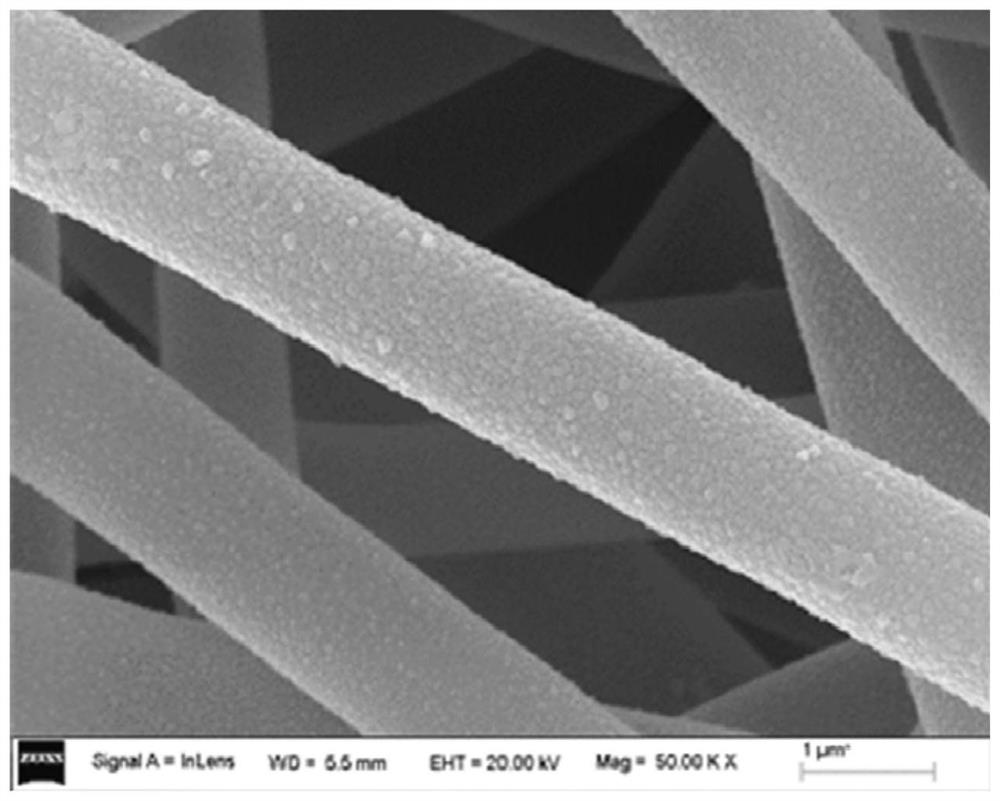

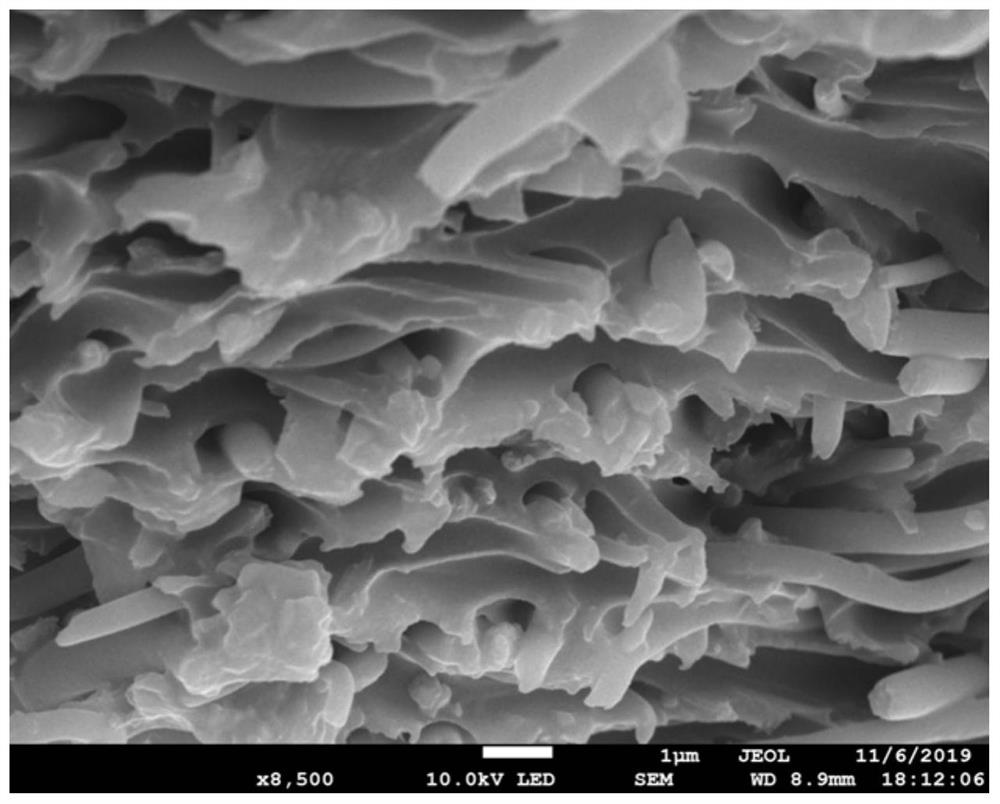

[0030] A. Using BTDA and ODA as a monomer to synthesize a polyamic acid solution with a solid content of 15wt% in DMAc, the curvature is 5m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 50 μm is spun by electrospinning on a parabolic substrate;

[0031] B. Soak the nanofibrous membrane obtained in step A in 0.1M silver nitrate solution for 20min to carry out ion exchange, the consumption of soluble silver salt solution is 2g / cm 2 Polyamic acid nanofiber membrane, and the nanofiber membrane is micro-crosslinked under the induction of metal ions, and after washing and drying, a parabolic anchored polyamic acid network insoluble in DMAc is formed;

[0032] C. Mix the polyamic acid solution with a solid content of 12% and silver trifluoroacetylacetonate (AgTFA) according to the silver content of 13wt% and stir vigorously until uniform, and the parabolic anchored polyamic acid network obtained in step B flows upstream Extend into a film with a thickness of 30...

Embodiment 2

[0035] A. Using BTDA and ODA as a monomer to synthesize a polyamic acid solution with a solid content of 15wt% in DMAc, the curvature is 5m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 10 μm is spun by electrospinning on a parabolic substrate;

[0036] B. Soak the nanofibrous membrane obtained in step A in 0.1M silver nitrate solution for 20min to carry out ion exchange, the consumption of soluble silver salt solution is 2g / cm 2 Polyamic acid nanofiber membrane, and the nanofiber membrane is micro-crosslinked under the induction of metal ions, and after washing and drying, a parabolic anchored polyamic acid network insoluble in DMAc is formed;

[0037] C. Mix the polyamic acid solution with a solid content of 12% and silver trifluoroacetylacetonate (AgTFA) according to the silver content of 13wt% and stir vigorously until uniform, and the parabolic anchored polyamic acid network obtained in step B flows upstream Extend into a film with a thickness of 30...

Embodiment 3

[0040] A. Using BTDA and ODA as a monomer to synthesize a polyamic acid solution with a solid content of 15wt% in DMAc, the curvature is 5m -1 A parabolic polyamic acid nanofiber membrane with a thickness of 10 μm is spun by electrospinning on a parabolic substrate;

[0041]B. Soak the nanofibrous membrane obtained in step A in 0.2M silver nitrate solution for 20min to carry out ion exchange, the consumption of soluble silver salt solution is 2g / cm 2 Polyamic acid nanofiber membrane, and the nanofiber membrane is micro-crosslinked under the induction of metal ions, and after washing and drying, a parabolic anchored polyamic acid network insoluble in DMAc is formed;

[0042] C. Mix the polyamic acid solution with a solid content of 12% and silver trifluoroacetylacetonate (AgTFA) according to the silver content of 13wt% and stir vigorously until uniform, and the parabolic anchored polyamic acid network obtained in step B flows upstream Extend into a film with a thickness of 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com