Flexible honeycomb bimetallic nitride supercapacitor electrode and preparation method thereof

A supercapacitor and bimetal technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, electrolytic capacitors, etc., can solve the problems of limited nickel-cobalt nitride materials, insufficient superelectric performance, and cumbersome process. The effect of excellent cycle performance, excellent cycle stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a flexible honeycomb double metal nitride electrode, comprising the following steps:

[0039] S1. Dissolve cobalt nitrate and nickel nitrate in 30mL methanol, then add 2-methylimidazole and continue to stir for 0.5h to obtain a mixed solution; wherein, in the mixed solution, the molar concentration of cobalt nitrate, nickel nitrate, and 2-methylimidazole 10mmol / L, 10mmol / L, 40mmol / L respectively;

[0040] S2. Put the flexible porous carbon cloth into 1M hydrochloric acid, acetone, ethanol and deionized water in sequence, and after each ultrasonic cleaning for 10 min, vacuum dry at 60° C. for 12 h.

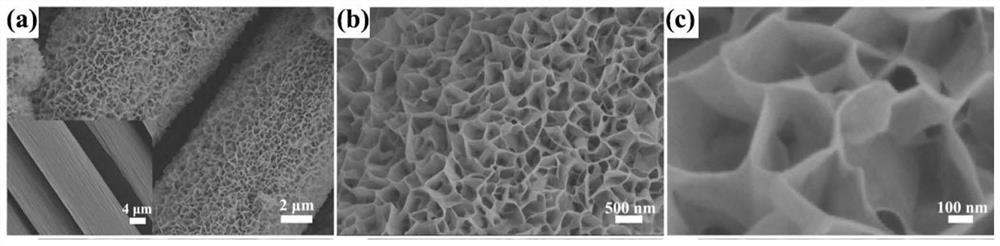

[0041] S3. Put the above mixed solution and the cleaned flexible porous carbon cloth into an autoclave in turn, and keep them warm at 120° C. for 14 hours to obtain a Ni-Co LDH / CC precursor film;

[0042] S4. Place the Ni-Co LDH / CC precursor thin film in a tube furnace, inject flowing ammonia gas into the tube furnace, raise the temperature of the tub...

Embodiment 2

[0044] A kind of preparation method of flexible honeycomb double metal nitride electrode

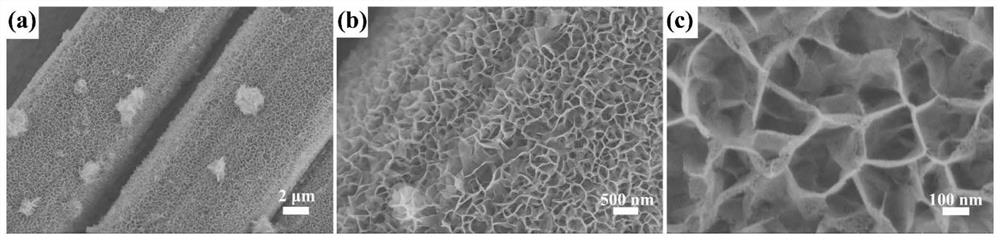

[0045] Compared with Example 1, the only difference is that S4 is different, specifically:

[0046] S4. Place the Ni-Co LDH / CC precursor thin film in a tube furnace, inject flowing ammonia gas into the tube furnace, raise the temperature of the tube furnace to 200 °C at a rate of 2 °C / min, and keep it for 2 hours to obtain Ni -Co-N / CC porous film.

Embodiment 3

[0048] A kind of preparation method of flexible honeycomb double metal nitride electrode

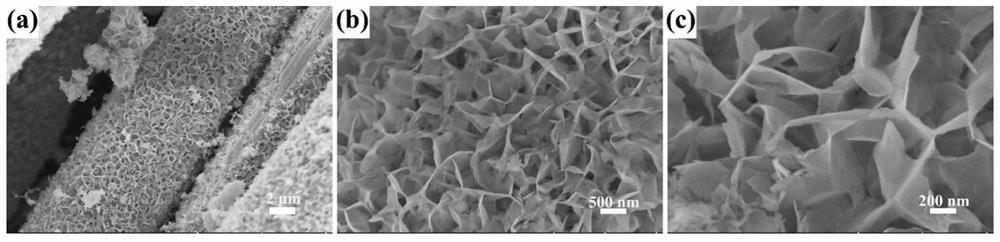

[0049] Compared with Example 1, the only difference is that S4 is different, specifically:

[0050] S4. Place the Ni-Co LDH / CC precursor thin film in a tube furnace, inject flowing ammonia gas into the tube furnace, raise the temperature of the tube furnace to 400 °C at a rate of 2 °C / min, and keep it for 2 hours to obtain Ni -Co-N / CC porous film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com