Method for preparing small-grain SAPO-34 molecular sieve

A SAPO-34, molecular sieve technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of accelerated equipment corrosion, expensive template agent, and increased operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

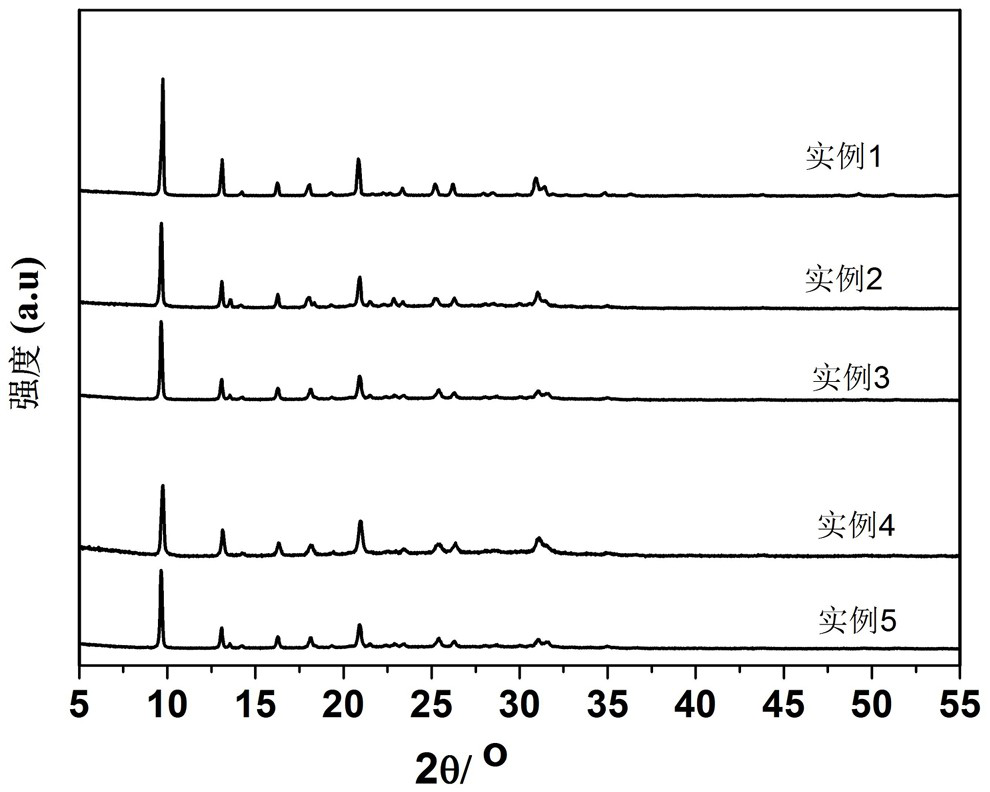

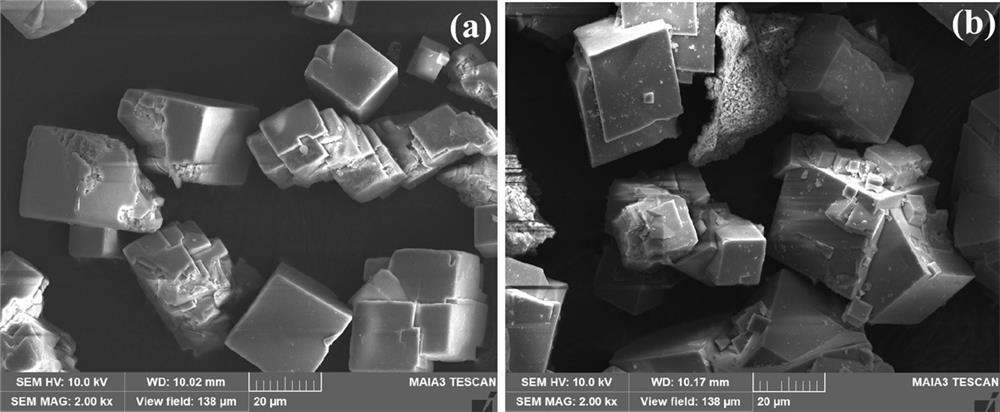

Embodiment 1

[0021] Add 16.4 g of aluminum isopropoxide to 46 g of water and stir magnetically at room temperature for 3 h, add 8.5 g of phosphoric acid and continue stirring for 1 h, then add 14.5 g of hectorite gel with a mass fraction of 8% and stir for 1 h, and finally add 2.5 g tetraethyl orthosilicate, stirred for 3 h to form an initial gel. The gel was stirred at 80 ºC for 12 h to prepare dry gel, which was ground into powder. Take 7.0 g of dry glue and place it in the upper part of the reactor, and the lower part of the reactor is a mixed solution of 4.9 g of morpholine and 4.9 g of water, and crystallize the reactor at 180ºC for 36 h. After the reaction, the product was fully washed, filtered, dried in an oven at 100 ºC for 5 h, and calcined at 550 ºC for 8 h to obtain small-grained SAPO-34 molecular sieves.

Embodiment 2

[0027] Add 16.4 g of aluminum isopropoxide to 40 g of water and stir magnetically at room temperature for 3 h, add 8.5 g of phosphoric acid and continue stirring for 1 h, then add 19.2 g of laponite gel with a mass fraction of 8 wt% and stir for 1 h, and finally add 1.25 g of orthosilicon Acetate tetraethyl ester, stirred for 3 h to form an initial gel. The gel was stirred at 80 ºC for 12 h to prepare dry gel, which was ground into powder. Take 7.0 g of dry glue and place it in the upper part of the reactor, and the lower part of the reactor is a mixed solution of 4.9 g of morpholine and 4.9 g of water, and crystallize the reactor at 180ºC for 36 h. After the reaction, the product was fully washed, filtered, dried in an oven at 100 ºC for 5 h, and calcined at 550 ºC for 8 h to obtain small-grained SAPO-34 molecular sieves.

Embodiment 3

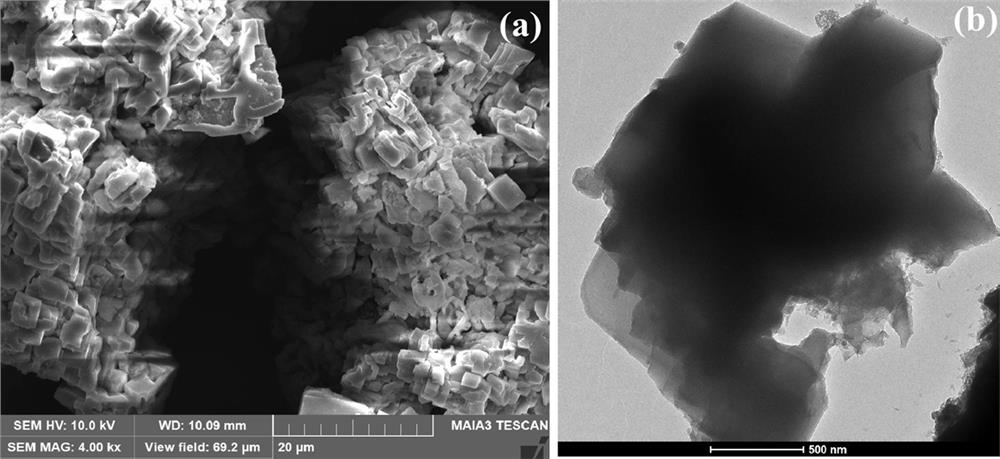

[0029]Add 16.4g of aluminum isopropoxide into 48g of water and stir magnetically at room temperature for 3h, add 8.5g of phosphoric acid and continue stirring for 1h, then add 9.6g of hectorite gel with a mass fraction of 8 wt% and stir for 1h, and finally add 3.75g of orthosilicon Acid tetraethyl ester, stirred for 3h to form an initial gel. The gel was stirred at 80 ºC for 12 h to prepare dry gel, which was ground into powder. Take 7.0g of dry glue and place it in the upper part of the reactor, and the lower part of the reactor is a mixed solution of 4.9 g of morpholine and 4.9 g of water, and crystallize the reactor at 180 ºC for 36 h. After the reaction, the product was fully washed, filtered, dried in an oven at 100 ºC for 5 h, and calcined at 550 ºC for 8 h to obtain small-grained SAPO-34 molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com