Method for preparing nano-structure transition metal nitride thin film by using plasma

A nanostructure and plasma technology, applied in the direction of nitrogen-metal/silicon/boron binary compounds, nitrogen compounds, chemical instruments and methods, etc., can solve the difficulty of uniform co-deposition of multi-element alloys, not suitable for engineering batch preparation, instruments and equipment High price and other problems, to achieve the effect of adjustable size, stable properties and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

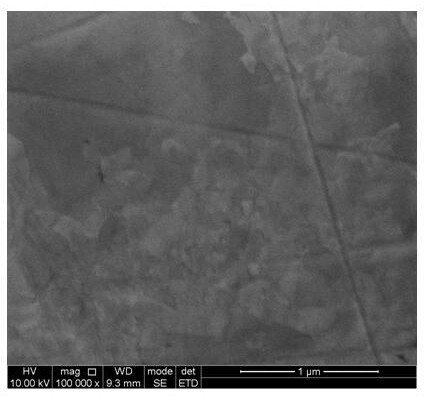

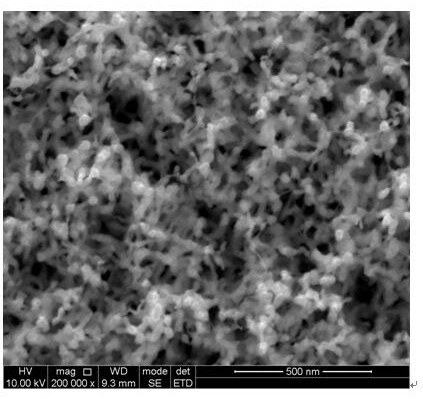

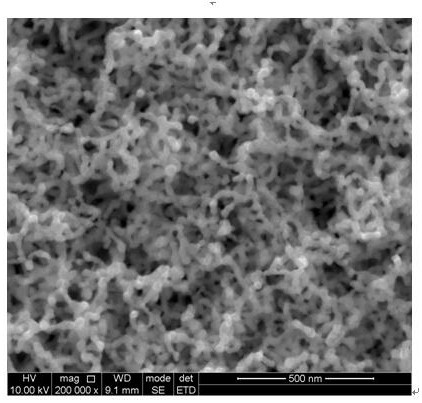

[0022] figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, the method for preparing a nanostructured transition metal nitride film using plasma uses a "cascade" arc discharge plasma device as the preparation device, and the preparation process includes Five steps; Step (1) Mechanically polish the bulk metal sample to the mirror surface, then use deionized water, ethanol and acetone for ultrasonic cleaning, dry it with a dryer and put it into the target chamber of the plasma equipment; Step ( 2) Vacuum the "cascaded" arc discharge plasma equipment, and then pass in Ar gas to perform sputter cleaning on the surface of the sample. After sputter cleaning and bombardment for a period of time, then pass in He gas to adjust the discharge current of the plasma equipment , the metal sample substrate is bombarded with high-energy He gas ions by plasma equipment for a period of time, and the surface of the metal sample is activated to form a metal elemental nano-fluff substrate; step (3) During ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com