Tin sulfide/tin disulfide heterojunction material and preparation method thereof

A technology of tin disulfide and tin sulfide, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the pollution of heterojunction surface interface, heterogeneous interface is prone to defects, and the quality of heterogeneous crystals is low and other problems, to achieve the effect of simple preparation process, high repeatability and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

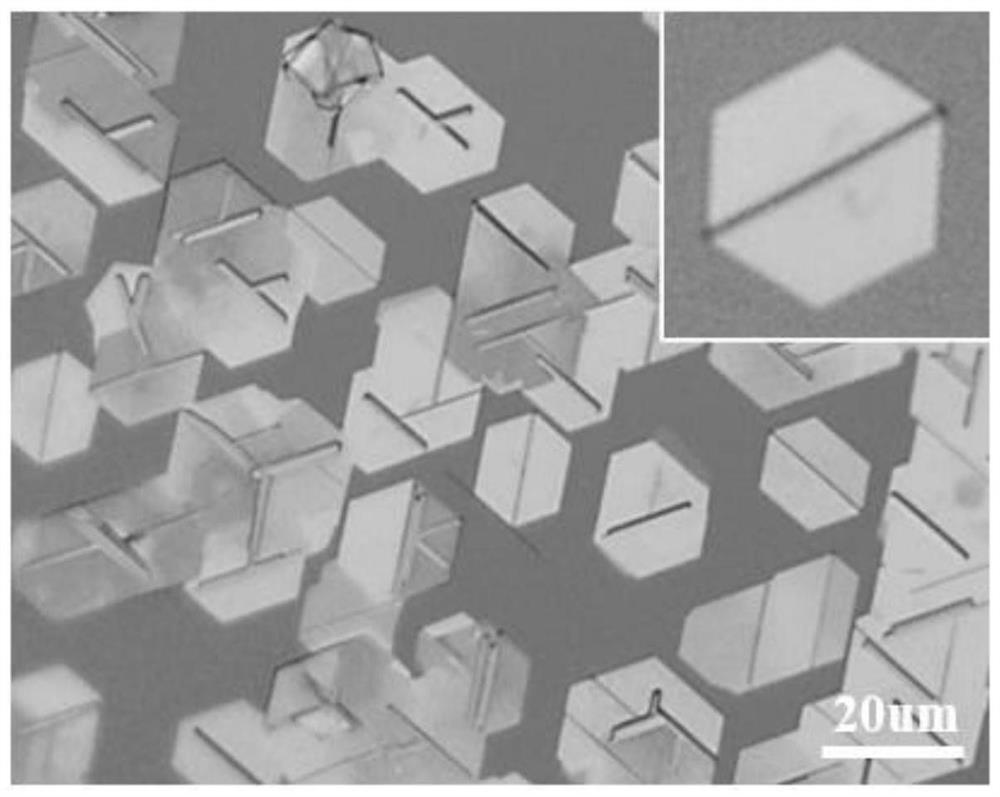

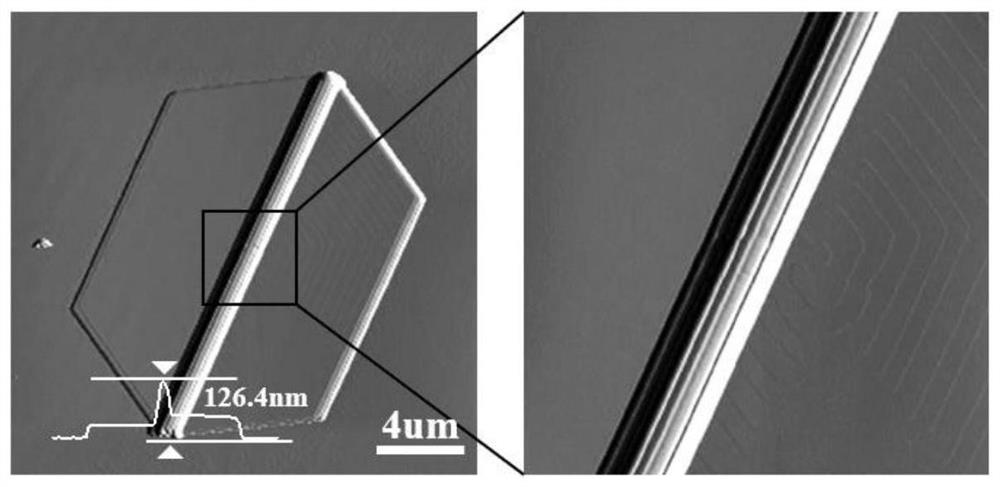

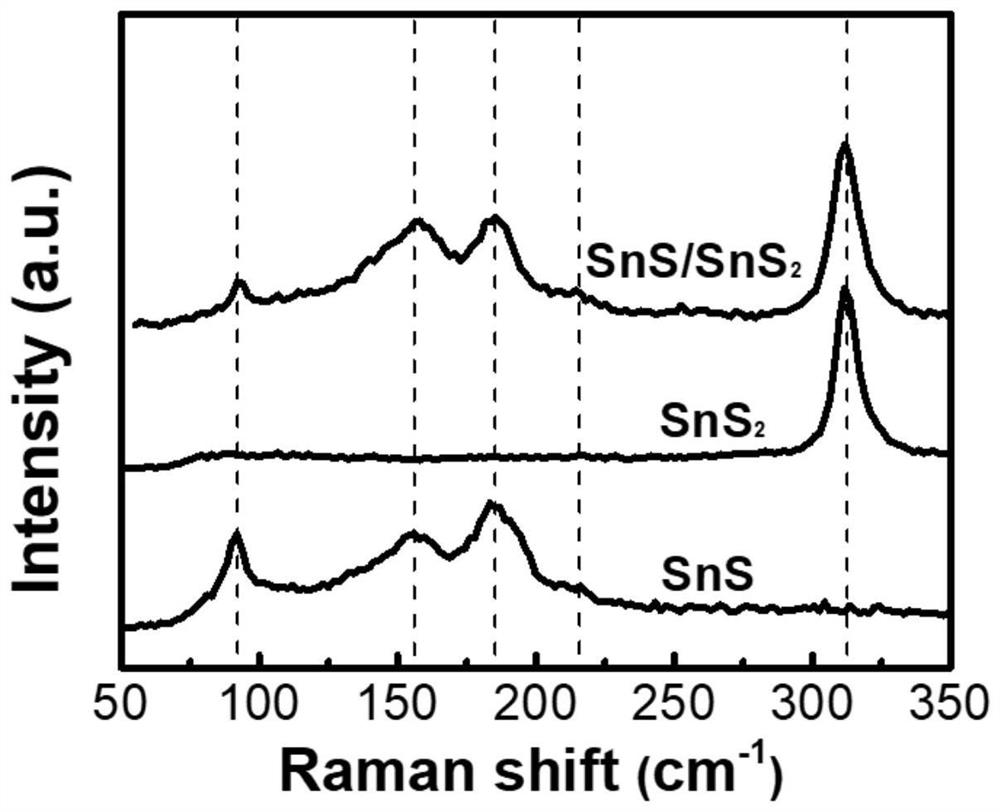

[0026] A one-dimensional tin sulfide / two-dimensional tin disulfide heterojunction and a preparation method thereof, comprising the following steps:

[0027] Step 1: Wipe the three-temperature zone CVD tube furnace clean with absolute ethanol, and anneal at a high temperature of 600°C for 10 minutes, and flush with 500 sccm of high-purity argon during the annealing;

[0028] Step 2: Weigh 150mg of sulfur powder (S) and 50mg of tin sulfide powder (SnS) respectively into the quartz boat; place the quartz boat with S powder in the first temperature zone of the three-temperature zone CVD tube furnace, load The quartz boat with SnS powder is placed in the second temperature zone; at the same time, the freshly peeled fluorophlogopite substrate is placed in the downstream direction of the SnS powder, with a distance of 6cm;

[0029] Step 3: Pump the CVD tube furnace, first turn on the mechanical pump to reduce the pressure in the furnace to 5Pa, then turn on the molecular pump to pump...

Embodiment 1

[0034]Wipe the three-temperature-zone CVD tube furnace clean with absolute ethanol, and anneal at 600°C for 10 minutes, and flush with 500 sccm of high-purity argon during annealing; weigh 150 mg of S powder and 50 mg of SnS powder respectively, and place them in a quartz boat; Place the quartz boat with S powder in the first temperature zone of the three-zone CVD tube furnace, place the quartz boat with SnS powder in the second temperature zone, and put the freshly peeled fluorophlogopite substrate into In the CVD tube furnace, it is located 6cm downstream of the SnS powder; after checking the airtightness of the CVD tube furnace, pump the CVD tube furnace, first turn on the mechanical pump to reduce the air pressure to 5 Pa, and then turn on the molecular pump to pump to below 2 Pa; then use 500sccm high-purity argon to quickly inflate the CVD tube furnace to standard atmospheric pressure; raise the temperature of the S powder temperature zone and the SnS temperature zone at ...

Embodiment 2

[0037] Wipe the three-temperature-zone CVD tube furnace clean with absolute ethanol, and anneal at 600°C for 10 minutes, and flush with 500 sccm of high-purity argon during annealing; weigh 150 mg of S powder and 50 mg of SnS powder respectively, and place them in a quartz boat; Place the quartz boat with S powder in the first temperature zone of the three-zone CVD tube furnace, place the quartz boat with SnS powder in the second temperature zone, and put the freshly peeled fluorophlogopite substrate into In the CVD tube furnace, it is located 6cm downstream of the SnS powder; after checking the airtightness of the CVD tube furnace, pump the CVD tube furnace, first turn on the mechanical pump to reduce the air pressure to 5 Pa, and then turn on the molecular pump to pump to below 2 Pa; then use 500sccm high-purity argon to quickly inflate the CVD tube furnace to standard atmospheric pressure; raise the temperature of the S powder temperature zone and the SnS temperature zone at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com