High-power sweetening agent for improving taste and mouth feel of mogroside and preparation method of high-power sweetening agent

A technology of mogroside and high-intensity sweetener, which is applied in chemical instruments and methods, medical preparations of non-active ingredients, pharmaceutical formulas, etc., and can solve the problem of product residue, failure to effectively separate, and lack of adjustment process technology, etc. problem, to achieve the effect of changing the powder form, improving the taste of the product, and improving the taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

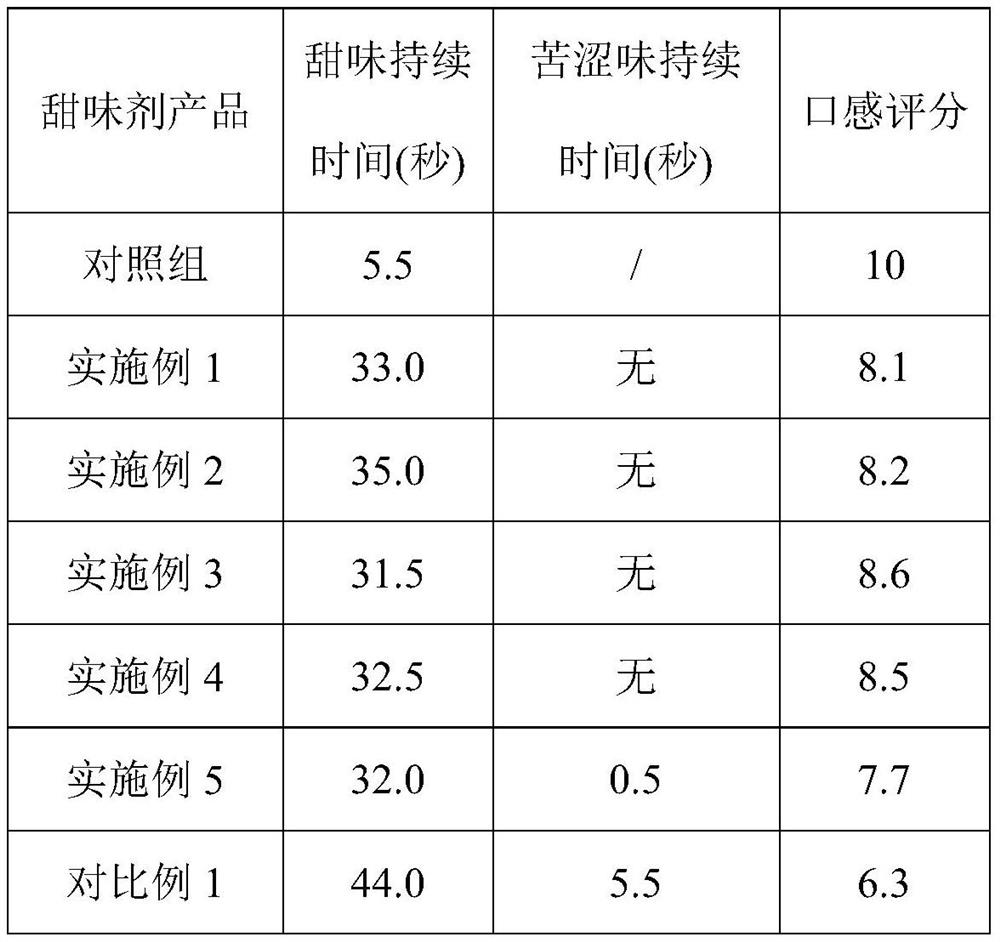

Examples

preparation example 1

[0070] Preparation example 1 Cross-linking modification of XDA-200B resin

[0071] Add 1kg of XDA-200B resin, 3.5L of BCMB, and 12L of carbon tetrachloride into a stirred reactor, let it swell for 10 hours, add 0.2kg of anhydrous zinc chloride, and react at 60°C for 12 hours, After the reaction, wash with absolute ethanol and deionized water until no precipitation occurs after adding the nitrate solution to obtain chloromethylated XDA-200B resin. Chloromethylated XDA-200B resin was added to 12L dimethyl sulfoxide after water removal to swell for 8 hours, and slowly added 0.2kg anhydrous aluminum chloride, 0.1kg anhydrous zinc chloride and 0.08kg triethylenetetramine , heated to 50°C and reacted for 12 hours under stirring conditions, filtered, washed with absolute ethanol and deionized water respectively, until no precipitation occurred after adding the nitrate solution, put the obtained resin in a blower dryer, and vacuum-dried overnight at 60°C, A cross-linked modified XDA-...

preparation example 2

[0073] Preparation example 2 Cross-linking modification of LSA-5B resin

[0074] Add 1kg of LSA-5B resin, 3.5L of BCMB, and 12L of carbon tetrachloride into a stirred reactor, let it swell for 10 hours, add 0.2kg of anhydrous zinc chloride, and react at 60°C for 12 hours, After the reaction, wash with absolute ethanol and deionized water until no precipitation occurs after adding the nitrate solution to obtain chloromethylated LSA-5B resin. Chloromethylated LSA-5B resin was added to 12L dimethyl sulfoxide after water removal to swell for 8h, slowly added 0.2kg anhydrous aluminum chloride, 0.1kg anhydrous zinc chloride and 0.12k ethylenediamine, and heated React at 50°C for 12h under stirring conditions, filter, wash with absolute ethanol and deionized water respectively, until no precipitation occurs after adding the nitrate solution, place the obtained resin in a blower dryer, and vacuum dry overnight at 60°C to obtain cross-linked Co-modified LSA-5B resin.

[0075] After t...

Embodiment 1

[0077] (1) 80kg of LX-17 resin is preliminarily packed in a stainless steel chromatography column and treated with ethanol, 4% sodium hydroxide aqueous solution, and 4% hydrochloric acid according to the standard procedure for regeneration of macroporous adsorption resin for use. Take 10kg of mogroside V50 powder, add 150L of purified water, stir to dissolve, then pass the solution through a chromatographic column equipped with LX-17 resin, and collect the feed effluent; after feeding the material, add 130L of purified water to wash the resin column , collect the washing solution, and combine the feed effluent and the washing solution.

[0078] (2) 18kg of XDA-200B resin is preliminarily packed in a stainless steel chromatography column and treated with ethanol, 4% sodium hydroxide aqueous solution, and 4% hydrochloric acid according to the standard procedure for regeneration of macroporous adsorption resin for use. Pass the combined liquid obtained in step (1) through the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com