Injectable high-pressure-resistant high-strength anti-freezing genipin cross-linked gelatin hydrogel and preparation method thereof

A technology of cross-linked gelatin and genipin, which is applied in the field of preparation of injectable high-pressure-resistant and high-strength freeze-resistant genipin cross-linked gelatin hydrogel, which can solve the problems of safety and potential risks, cytotoxicity, permanent It can achieve excellent frost resistance, long-term stability, excellent anti-fatigue and pressure resistance, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

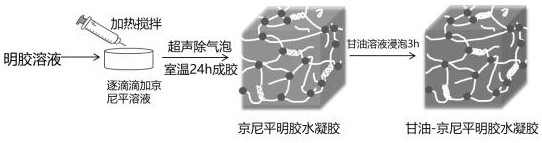

[0035] A preparation method for injectable genipin cross-linked gelatin hydrogel with high pressure resistance, high strength and fatigue resistance, comprising the steps of:

[0036] (1) Dissolve 0.01 g of genipin in ethanol solution, shake and dissolve with an oscillator, and prepare a 1wt% genipin solution;

[0037] (2) Dissolve 2.5g of gelatin in 9ml of deionized water, heat and stir at 50°C to dissolve, and prepare a gelatin solution;

[0038] (3) Use a 1ml syringe to absorb 1wt% genipin solution, add it drop by drop (1 drop per second) to the gelatin solution, heat and stir the mixed solution at 50°C for 14 minutes, ultrasonically remove air bubbles, and stand at room temperature for 24 hours to obtain 0.1GP25GEL (genipin mass fraction 0.1wt%, gelatin mass fraction 25wt%).

[0039] (4) Prepare a glycerin solution with a mass ratio (water:glycerol) of 1:2. Soak 0.1GP25GEL in different glycerin solutions for 3h.

[0040] (5) Take out the soaked hydrogel and rinse with d...

Embodiment 2

[0046] A preparation method of high pressure resistance and high strength genipin cross-linked gelatin hydrogel, comprising the steps of:

[0047] (1) Dissolve 0.05 g of genipin in ethanol solution, shake and dissolve with an oscillator, and prepare a 5wt% genipin solution;

[0048] (2) Dissolve 2.5g of gelatin in 9ml of deionized water, heat and stir at 50°C to dissolve, and prepare a gelatin solution;

[0049] (3) Use a 1ml syringe to absorb 5wt% genipin solution, add it drop by drop (1 drop per second) to the gelatin solution, heat and stir the mixed solution at 50°C for 11 minutes, ultrasonically remove air bubbles, and stand at room temperature for 24 hours to obtain 0.5GP25GEL (genipin mass fraction 0.5wt%, gelatin mass fraction 25wt%).

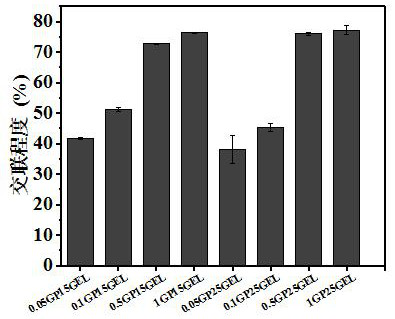

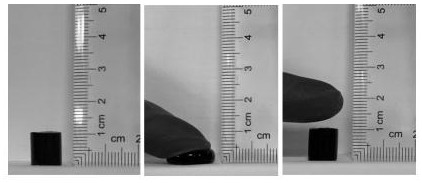

[0050] Such as figure 2 and Figure 4 As shown, the water content of 0.5GP25GEL is 73.5%, the degree of crosslinking is 75.97%; under the strain of 97%, the compressive fracture stress is 10.95MPa, which has high fracture strength. ...

Embodiment 3

[0052] A preparation method for low-strength genipin cross-linked gelatin hydrogel, comprising the steps:

[0053] (1) Dissolve 0.005g of genipin in ethanol solution, shake and dissolve with an oscillator, and prepare a 0.5wt% genipin solution;

[0054] (2) Dissolve 0.5g of gelatin in 9ml of deionized water, heat and stir at 50°C to dissolve, and prepare a gelatin solution;

[0055] (3) Draw up 0.5wt% genipin solution with a 1ml syringe, add it drop by drop (1 drop per second) into the gelatin solution, heat and stir the mixed solution at 50°C for 40 min, remove bubbles by ultrasonic waves, and let stand at room temperature for 24 hours to obtain 0.05GP5GEL (genipin mass fraction 0.05wt%, gelatin mass fraction 5wt%).

[0056] Such as Figure 4 As shown, 0.05GP5GEL has a compressive fracture stress of 0.21MPa under a strain of 75%, and its fracture compressive stress and strain are relatively weak, which are lower than the gelatin hydrogel in the most suitable genipin concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com