Preparation method of heat-insulating and flame-retardant composite aerogel foam

A flame retardant composite and composite gel technology, which is applied in airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem of poor compatibility between inorganic flame retardants and polymer foam resins, and the flame retardant effect cannot meet the requirements , organic flame retardants are not environmentally friendly, etc., to achieve the effect of short gel time, low shrinkage rate, good heat insulation and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

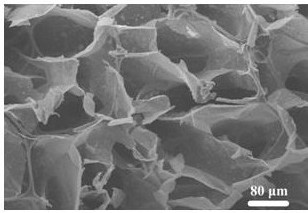

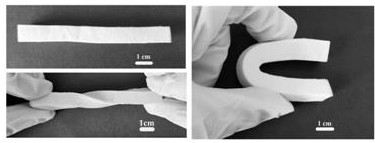

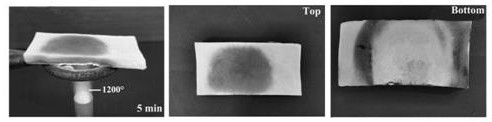

Embodiment approach 1

[0024] Attapulgite was uniformly dispersed in water to prepare 50 mL of attapulgite slurry with a concentration of 3 wt%. Chitosan was uniformly dispersed in an acetic acid solution with a pH of 4 to prepare 50 ml of chitosan sol with a concentration of 2 wt%. The attapulgite slurry and chitosan sol were uniformly mixed at a volume ratio of 1:0.5, stirred at a constant speed at 1000 rpm for 30 min, and then 3 mL of glutaraldehyde solution with a mass concentration of 2.5% was added as a crosslinking agent, and the stirring was continued. Obtain attapulgite-chitosan composite slurry uniformly. The melamine foam was evenly immersed in the attapulgite-chitosan composite slurry, and the foam was evenly squeezed for 5 min to make the attapulgite-chitosan composite slurry filled with the melamine foam. Soak the melamine foam with attapulgite-chitosan composite slurry in an alkaline solution with pH=10 to form a gel, and age the gel for 24 hours to obtain a composite gel foam. The ...

Embodiment approach 2

[0026] The sepiolite was uniformly dispersed in water to prepare 50 mL of sepiolite slurry with a concentration of 5 wt%. Sodium alginate was uniformly dispersed in aqueous solution to prepare 50 ml of sodium alginate sol with a concentration of 0.5 wt%. The above-mentioned sepiolite slurry and sodium alginate sol were uniformly mixed at a volume ratio of 1:0.2, stirred at a constant speed at 1000 rpm for 30 min, and then 1 mL of glutaraldehyde solution with a mass concentration of 2.5% was added as a crosslinking agent. Continue to stir evenly to obtain sepiolite-sodium alginate composite slurry. The melamine foam was evenly immersed in the sepiolite-sodium alginate composite slurry, and the foam was evenly squeezed for 10 min to fill the sepiolite-sodium alginate composite slurry with the melamine foam. Soak the melamine foam with sepiolite-sodium alginate composite slurry in the aqueous solution, add 1 mL of 1 wt% calcium chloride solution to form a gel, and age the gel fo...

Embodiment approach 3

[0028] Halloysite was uniformly dispersed in water to prepare 50 mL of halloysite slurry with a concentration of 4 wt%. Pectin was uniformly dispersed in aqueous solution to prepare 50 ml pectin sol with a concentration of 5 wt%. The above-mentioned halloysite slurry and pectin sol were uniformly mixed at a volume ratio of 1:1, and after stirring at a constant speed of 1000 rpm for 30 min, 1.5 mL of glutaraldehyde solution with a mass concentration of 2.5% was added as a crosslinking agent, continued Stir evenly to obtain halloysite pectin compound slurry. The melamine foam was evenly immersed in the halloysite-pectin composite slurry, and the foam was evenly squeezed for 8 min to fill the halloysite-pectin composite slurry with the melamine foam. Soak the melamine foam with halloysite-pectin composite slurry in the alkaline aqueous solution of pH=9, add 3 mL of 2.5 wt% calcium chloride solution to form a gel, and age the gel for 24 hours Composite gel foam. The above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com