A photothermally enhanced supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, copper sulfide, etc. It can solve the problems of poor electrode flexibility and stability, supercapacitor capacity decay, and easy shedding of active materials. Achieve the effect of accelerating kinetic process, improving electrochemical performance and increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

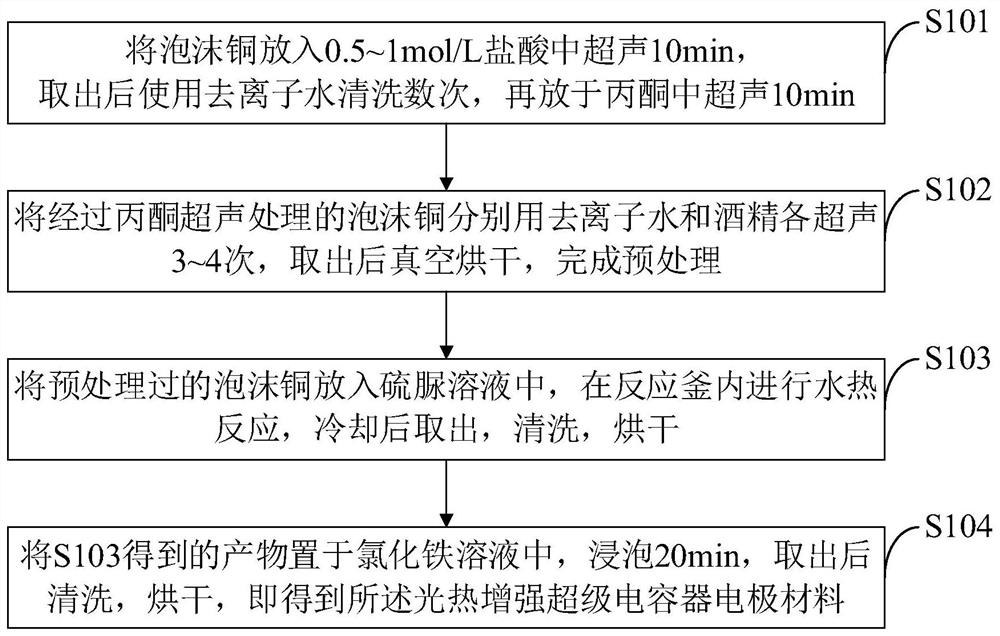

[0034] like figure 1 As shown, the preparation method of the photothermally enhanced supercapacitor electrode material provided by the embodiment of the present invention includes the following steps:

[0035] S101, put the foamed copper into 0.5-1 mol / L hydrochloric acid for 10 minutes, wash it with deionized water for several times after taking it out, and then put it in acetone for 10 minutes of ultrasound;

[0036] S102, the copper foam that has been ultrasonically treated with acetone is ultrasonicated 3 to 4 times with deionized water and alcohol respectively, taken out and dried in vacuum to complete the pretreatment;

[0037] S103, putting the pretreated copper foam into a thiourea solution, carrying out a hydrothermal reaction in the reactor, taking out after cooling, cleaning, and drying;

[0038] S104, the product obtained in S103 is placed in a ferric chloride solution, soaked for 20 minutes, taken out, cleaned, and dried to obtain the photothermally enhanced supe...

Embodiment 2

[0055] The preparation method of the supercapacitor electrode material with photothermal enhancement effect provided by the embodiment of the present invention comprises the following steps:

[0056] Step 1, cut the foam copper into 1cm*3cm, put it into 1mol / L hydrochloric acid for 10min, wash it with deionized water for 3 times after taking it out, and then put it in acetone for sonication for 10min; Deionized water and alcohol were used for ultrasonic 3 times respectively. After taking them out, they were dried in a vacuum drying oven at 50 °C to complete the pretreatment;

[0057] Step 2, weigh 90 mg of thiourea and add it to a mixed solution of 15 mL of absolute ethanol and 5 mL of deionized water, stir evenly to obtain a thiourea solution; put the pretreated foam copper into the thiourea solution, and transfer it to polytetrafluoroethylene. In the vinyl fluoride stainless steel reactor, hydrothermally reacted at 150 °C for 6 hours. After the reaction was completed, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com