Polyphosphazene-based hydrogel wound dressing with antibacterial and wet surface adhesion properties, and preparation method thereof

A wound dressing and hydrogel technology, applied in pharmaceutical formulations, pharmaceutical sciences, drug delivery, etc., can solve the problems of the wounded being unable to receive professional care, difficult to effectively control bleeding, unable to meet emergency hemostasis, etc. Effects of wound healing properties, excellent hemostatic properties, and good self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve 30.2 mg of polyphosphazene and 30.3 mg of polyvinyl alcohol in 970 μl of deionized water respectively, and wait until completely dissolved to obtain polyphosphazene solution and polyvinyl alcohol solution.

[0041] The polyphosphazene solution and the polyvinyl alcohol solution are mixed and stirred, the rotating speed is 500-1000 rpm, and the stirring time is 50-10 minutes to obtain a polyphosphazene-based hydrogel wound dressing with deionized water as a solvent.

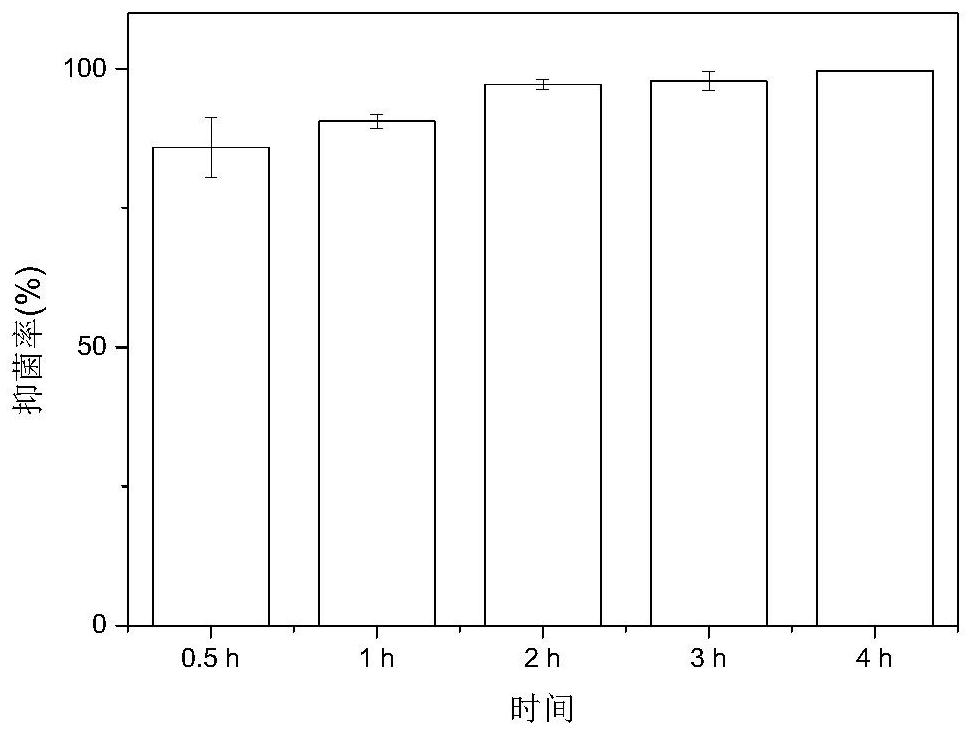

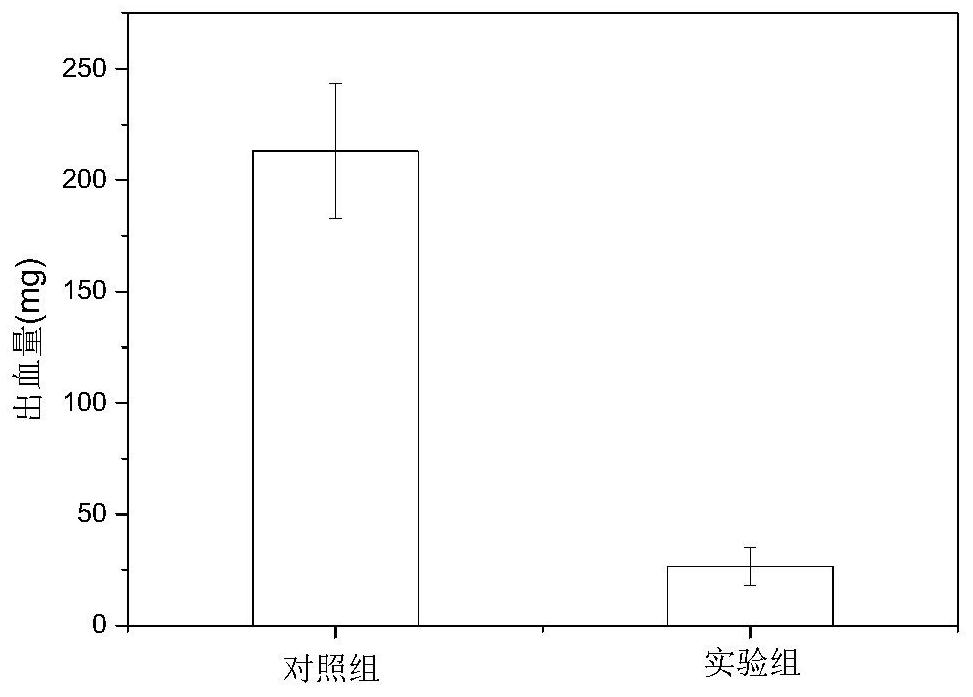

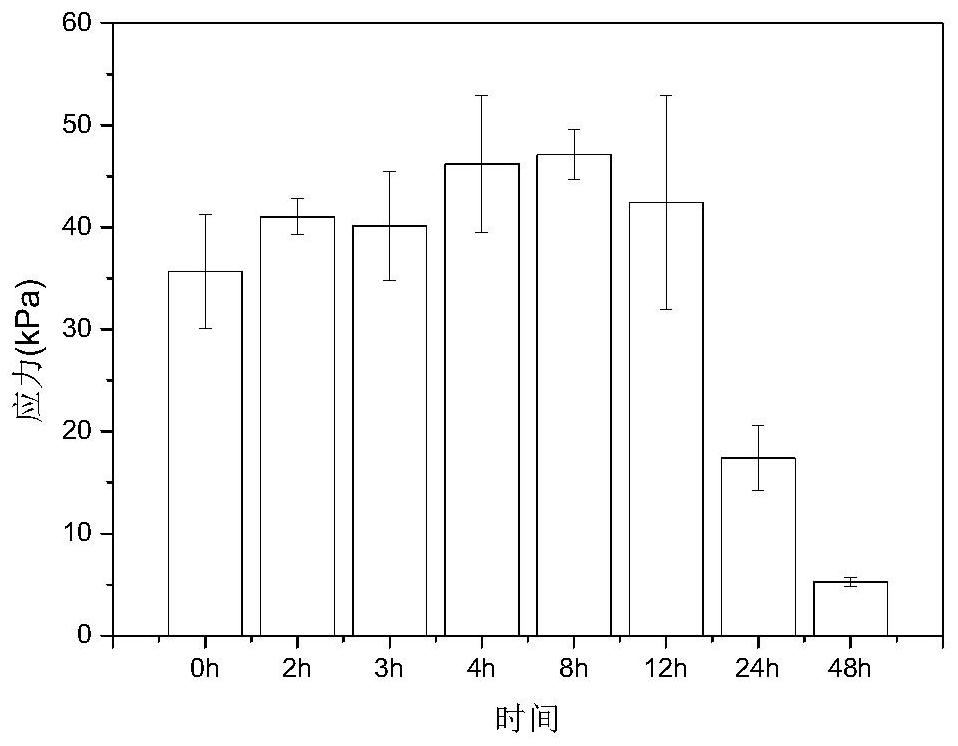

[0042] In the logarithmic growth phase, 10 μl of Escherichia coli ATCC25922 bacterial suspension with a concentration of 106 CFU was dispersed on the surface of the hydrogel wound dressing, and cultured in a 37°C constant temperature incubator for 0.5h, 1h, 2h, 3h and 4h. After co-cultivation, 1 ml of PBS solution was added to the surface of the hydrogel wound dressing and sonicated for 30 min. Take 100 μl of the solution to coat LB solid medium, culture overnight in a constant temperature incubato...

Embodiment 2

[0047] Dissolve 30.7 mg of polyphosphazene and 30.2 mg of polyvinyl alcohol in 970 μl of deionized water respectively, and wait until completely dissolved to obtain polyphosphazene solution and polyvinyl alcohol solution.

[0048] The polyphosphazene solution and the polyvinyl alcohol solution are mixed and stirred, the rotating speed is 500-1000 rpm, and the stirring time is 50-10 minutes to obtain a hydrogel wound dressing with deionized water as a solvent.

[0049] In the logarithmic growth phase, 10 μl of Escherichia coli ATCC25922 bacterial suspension with a concentration of 106 CFU was dispersed on the surface of the hydrogel wound dressing, and cultured in a 37°C constant temperature incubator for 0.5h, 1h, 2h, 3h and 4h. After co-cultivation, 1 ml of PBS solution was added to the surface of the hydrogel wound dressing and sonicated for 30 min. Take 100 μl of the solution to coat LB solid medium, culture overnight in a constant temperature incubator at 37°C, and count t...

Embodiment 3

[0054] Dissolve 30.6 mg of polyphosphazene and 30.8 mg of polyvinyl alcohol in 970 μl of deionized water respectively, and wait for complete dissolution to obtain polyphosphazene solution and polyvinyl alcohol solution.

[0055] The polyphosphazene solution and the polyvinyl alcohol solution are mixed and stirred, the rotating speed is 500-1000 rpm, and the stirring time is 50-10 minutes to obtain a hydrogel wound dressing with deionized water as a solvent.

[0056] In the logarithmic growth phase, 10 μl of Escherichia coli ATCC25922 bacterial suspension with a concentration of 106 CFU was dispersed on the surface of the hydrogel wound dressing, and cultured in a 37°C constant temperature incubator for 0.5h, 1h, 2h, 3h and 4h. After co-cultivation, 1 ml of PBS solution was added to the surface of the hydrogel wound dressing and sonicated for 30 min. Take 100 μl of the solution to coat LB solid medium, culture overnight in a constant temperature incubator at 37°C, and count the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com