Two-dimensional nano-hybrid composite anticorrosive coating filler as well as preparation method and application thereof

A two-dimensional nano, anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

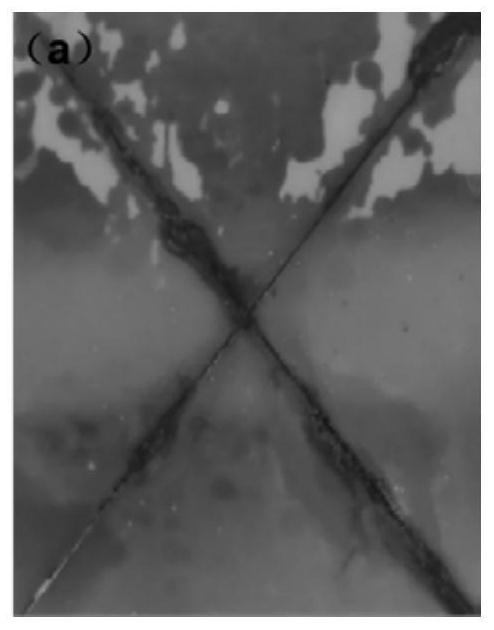

[0050] In this example, silane-functionalized graphene oxide nanosheets / g-C 3 N 4 The nanosheets were used as anti-corrosion nanofillers in a waterborne epoxy coating and applied by paint brush on a clean steel substrate.

[0051] g-C 3 N 4 Preparation of nanosheets: urea was used as a nitrogen-rich precursor, synthesized after heat treatment at 550°C for 2 hours in an alumina crucible with a cover, and then used.

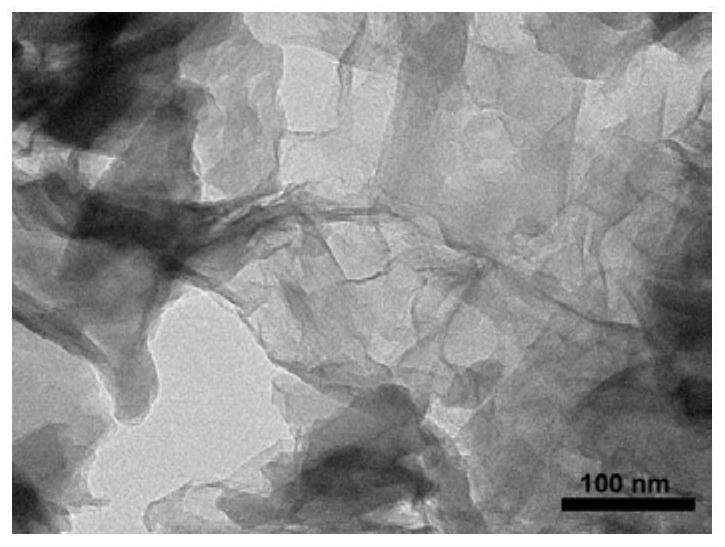

[0052] Then, a two-dimensional nano-hybrid material with a mass ratio of graphene oxide and g-C3N4 nanosheets of 1:1 was prepared by hydrothermal method: 0.5 g graphene oxide (50 ml graphene oxide with a concentration of 10 mg / ml) and 0.5 g g-C 3 N 4The nanosheets were distributed in 20ml ethanol, the bath was ultrasonicated for 60 minutes, followed by stirring at room temperature for 3h. The resulting mixture was transferred to a PTFE-lined stainless steel autoclave at 120 °C for 12 h to obtain graphene oxide / g-C 3 N 4 Two-dimensional nanohybridization of ...

Embodiment 2

[0065] In this example, silane-functionalized graphene oxide nanosheets / g-C 3 N 4 The nanosheets were used as anti-corrosion nanofillers in a waterborne epoxy coating and applied by paint brush on a clean steel substrate.

[0066] Using urea as a nitrogen-rich precursor, heat treatment in an alumina crucible to 550 °C for 2 hours to synthesize g-C 3 N 4 Nanosheets. Then, graphene oxide / g-C was prepared by solution mixing method 3 N 4 Nanosheets vs Graphene Oxide vs g-C 3 N 4 A two-dimensional nano-hybrid with a nanosheet weight ratio of 1:1. To this end, 50 mL of graphene oxide (concentration of graphene oxide solution is 10 mg / mL) was bath-sonicated in 50 mL of deionized water for 60 min. In another beaker, 0.5g g-C 3 N 4 The nanosheets were dispersed in 100 mL deionized water, and the bath was ultrasonically treated for 60 min. Then, it was added to the graphene oxide solution, continued bath sonication for 60 min, and then obtained by rotary evaporation at 80 °C....

Embodiment 3

[0071] Using the in situ synthesis method, 0.5 g of urea as a nitrogen-rich precursor was dissolved in 20 mL of deionized water by stirring at room temperature, and then 50 mL of graphene oxide solution (the concentration of graphene oxide solution was 10 mg / mL) was added. Stir vigorously at room temperature for 3 hours, and then dry at 80°C for 24 hours. The resulting product is placed in an alumina crucible with a cover, and heat-treated in a muffle furnace at 550°C for 2 hours to obtain graphene oxide / g-C 3 N 4 Nanosheet two-dimensional nanohybrid.

[0072] In the next step, for graphene oxide / g-C 3 N 4 Two-dimensional nanohybrids of nanosheets were functionalized with 3-aminopropyltriethoxysilane: 3-aminopropyltriethoxysilane was dissolved in deionized water at a volume ratio of 1:19, and 0.5 g of Two-dimensional nanohybrids. Then, the suspension was stirred and heated at 80° C. for 12 hours in a reflux system. Finally, the resulting suspension was centrifuged, washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com