Processing and preparing method of high-thermal-conductivity PCB substrate

A high thermal conductivity, substrate technology, applied in the processing of insulating substrates/layers, printed circuit manufacturing, printed circuits, etc., can solve the problems of low resin content, decreased resin fluidity, brittle fracture, etc. The effect of increasing the bulk density and increasing the filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

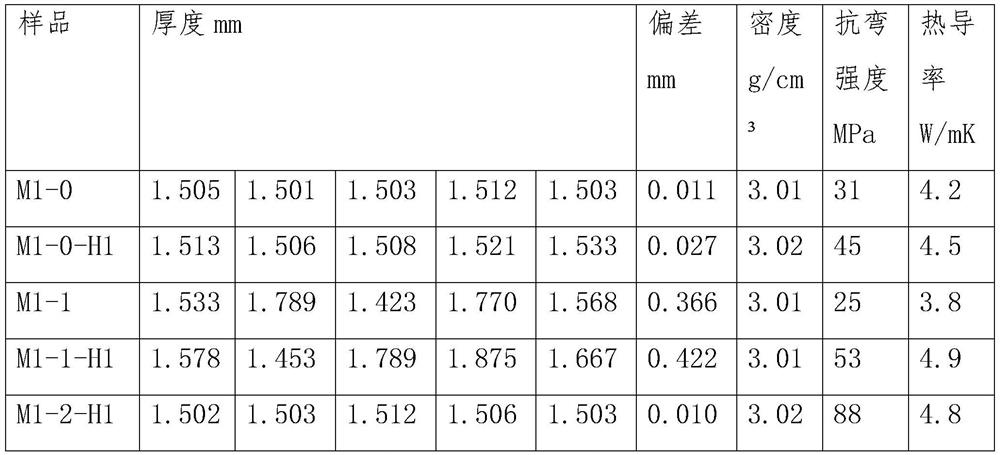

[0032] Weigh 15g of PPS (polyphenylene sulfide, Xinhecheng 11200F), 60g of corundum-type alumina particles of 300 mesh, and 25g of corundum-type alumina particles of 600 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0033] 100 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 200 MPa, a temperature of 300° C., and a pressing time of 20 min.

[0034] After cooling, the sample was taken out, and the sample was cut into 1.5mm thin slices with a diamond wire cutting machine (Tangshan Jingyu), marked as M1-0, and the thickness size distribution, thermal conductivity and mechanical properties were tested.

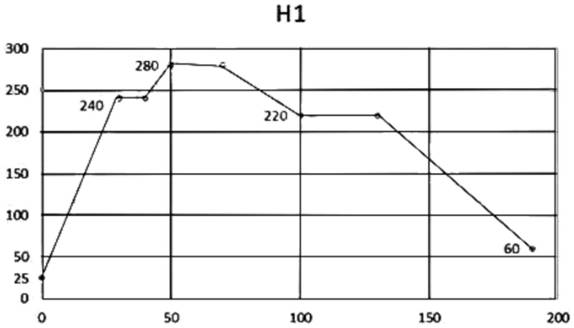

[0035] M1-0 is heat treated according to the curve H1, marked as M1-0-H1, and the thickness size distribution, thermal conductivity and mechanical properties are tested.

Embodiment 2

[0037] Weigh 15g of PPS (polyphenylene sulfide, Xinhecheng 11200F), 60g of corundum-type alumina particles of 300 mesh, and 25g of corundum-type alumina particles of 600 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0038] 10 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 200 MPa, a temperature of 300° C., and a pressing time of 20 min.

[0039] After cooling, the sample was taken out and marked as M1-1, and the thickness size distribution, thermal conductivity and mechanical properties were tested.

[0040] M1-1 is heat treated according to the curve H1, marked as M1-1-H1, and the thickness size distribution, thermal conductivity and mechanical properties are tested.

Embodiment 3

[0042] Weigh 15g of PPS (polyphenylene sulfide, Xinhecheng 11200F), 60g of corundum-type alumina particles of 300 mesh, and 25g of corundum-type alumina particles of 600 mesh. Mix in a small pulverizer for 10 seconds and set aside.

[0043] 10 g of the mixed sample was weighed, and hot-pressed in a circular mold with a diameter of 50 mm and a heating mantle at a pressure of 200 MPa, a temperature of 300° C., and a pressing time of 20 min.

[0044] After cooling, the sample was taken out, and after heat treatment according to molding H1, the sample was cut into 1.5mm thin slices with a diamond wire cutting machine (Tangshan Jingyu). Marked as M1-2-H1, testing thickness size distribution, thermal conductivity and mechanical properties.

[0045]

[0046] Such as figure 1 As shown, it is a graph of the heat treatment of the composite material body first, the ordinate is the temperature (°C), the abscissa is the time (min), the heat treatment temperature is 220°C-320°C, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com