Preparation method of sulfonated graphene oxide/polymer mixed matrix membrane used for gas separation

A mixed-matrix membrane and graphene technology, which is applied in separation methods, carbon compounds, chemical instruments and methods, etc., can solve the problems that the performance of mixed-matrix membranes cannot be optimized, the film formation process is difficult, and the long-term instability is achieved. Excellent performance, good stability, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

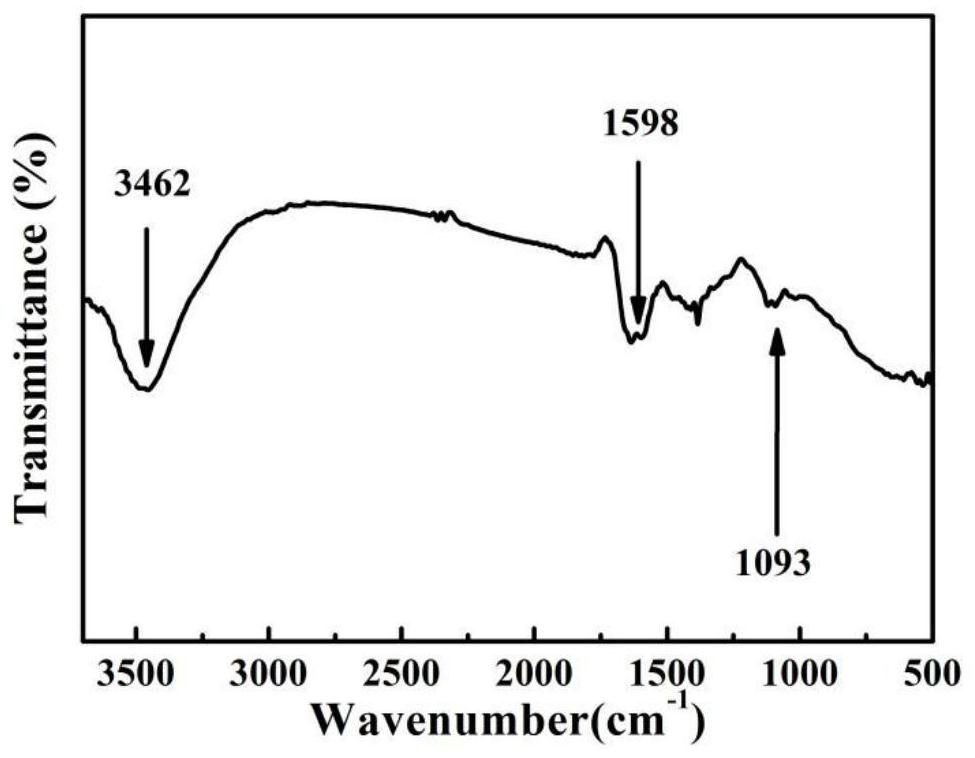

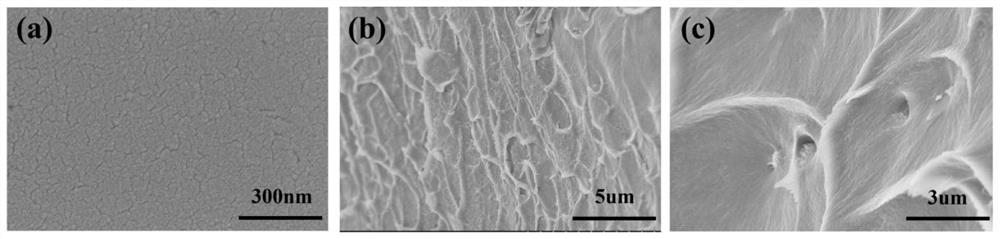

[0032] Example 1 Preparation of sulfonated reduced graphene oxide / polyimide mixed matrix membrane

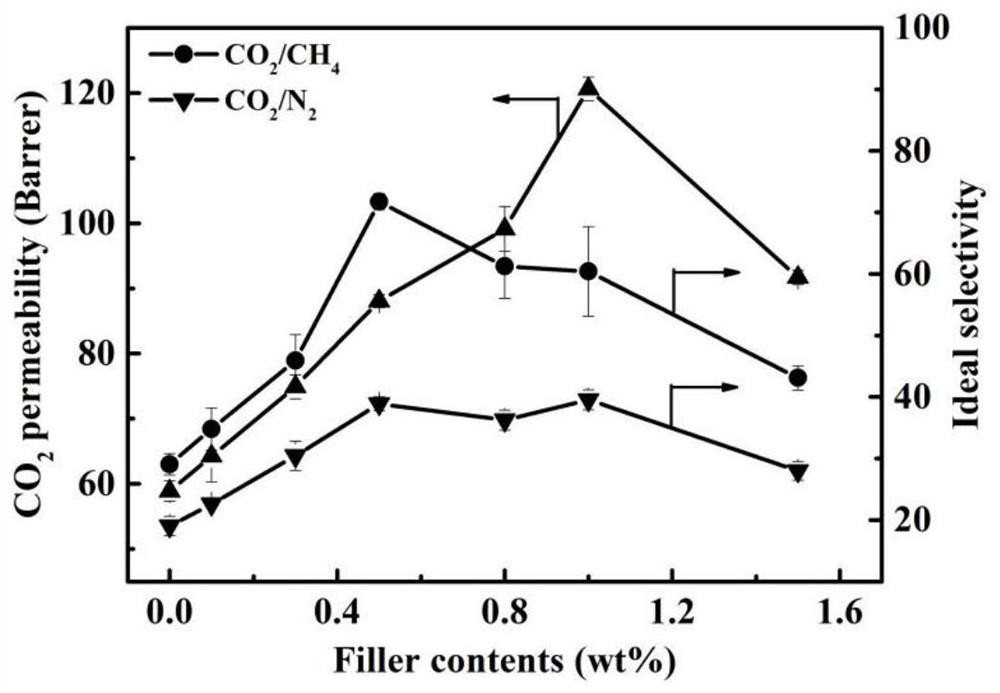

[0033] Take 0.005g of the prepared sulfonated reduced graphene oxide and 2mL N,N-dimethylacetamide to prepare a filler suspension, and dissolve 1g of polyimide polymer in 8mL of an organic solvent to prepare an organic casting solution. Blend the suspension with the casting solution to form a mixed matrix membrane casting solution, use the drop coating method to heat the film at 60°C, and peel off at 80°C (2h), 120°C (2h), 150°C (18h) . The stripped membrane material was placed in a gas permeation instrument, and the gas separation performance was tested at 35°C and 3 bar. Among them, the carbon dioxide permeation flux was 69.74 barrer, the carbon dioxide / methane separation coefficient was 81, and the carbon dioxide / nitrogen separation coefficient was 40.5; test its gas separation performance at 75°C and 3bar to test its high-temperature gas separation performance, in which the...

Embodiment 2

[0034] Example 2 Preparation of sulfonated reduced graphene oxide / polyimide mixed matrix membrane

[0035] Take 0.01g of the prepared sulfonated reduced graphene oxide and 2mL N,N-dimethylacetamide to form a filler suspension, and dissolve 1g of polyimide polymer in 8mL of an organic solvent to form an organic casting solution. Blend the suspension with the casting solution to form a mixed matrix membrane casting solution, use the drop coating method to heat the film at 60°C, and peel off at 80°C (2h), 120°C (2h), 150°C (18h) . Test its gas separation performance, in which the permeation flux of carbon dioxide is 103.3 barrer, the separation coefficient of carbon dioxide / methane is 45.4, and the separation coefficient of carbon dioxide / nitrogen is 19.9; the performance of high-temperature gas separation is tested, in which the permeation flux of carbon dioxide is 120.3 barrer, the separation coefficient of carbon dioxide / nitrogen is 120.3 barrer, The methane separation factor...

Embodiment 3

[0043] Example 3 Preparation of sulfonated reduced graphene oxide / cellulose acetate mixed matrix membrane

[0044] Take 0.005 g of the prepared sulfonated reduced graphene oxide and 2 mL of acetone to prepare a filler suspension, dissolve 1 g of cellulose acetate polymer in 8 mL of an organic solvent to prepare an organic film casting liquid, and mix the suspension with the film casting liquid Blend to form a mixed matrix membrane casting solution, use the drop coating method to heat the film at 60°C, and peel off at 80°C (2h), 120°C (2h), and 150°C (18h).

[0045] Gas separation performance test:

[0046] The stripped membrane material was placed in a gas permeation instrument, and the gas separation performance was tested at 35°C and 3 bar. Among them, the carbon dioxide permeation flux was 12.28 barrer, and the carbon dioxide / methane separation coefficient was 47.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com