Oil stain adsorbent and preparation method thereof

An adsorbent, oil pollution technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of difficult to remove oil pollution, without considering the effect of adsorbing emulsified oil to absorb oil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

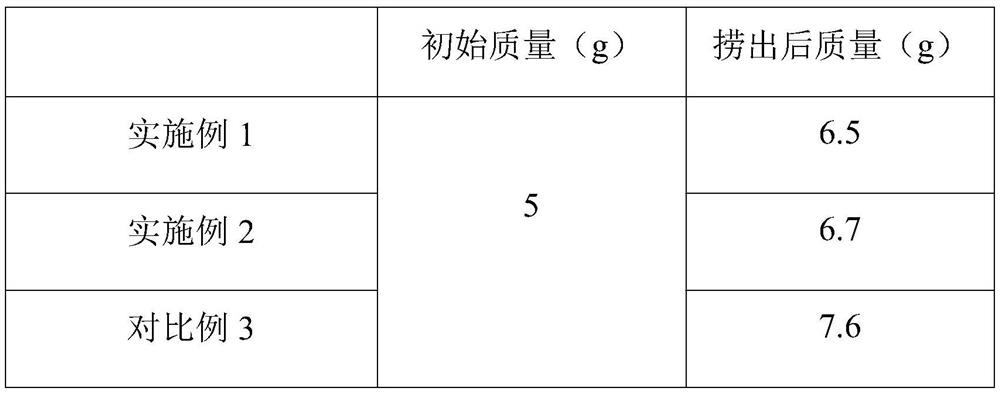

Examples

Embodiment 1

[0029] A kind of oil stain adsorbent, in parts by weight, mainly comprises:

[0030] 1 part of modified activated carbon, 2 parts of modified chitosan;

[0031] A kind of preparation of oil stain adsorbent, described oil stain adsorbent preparation method is:

[0032] (1) Mix the carbonaceous material and the calcium-aluminum hydrotalcite evenly according to the mass ratio of 8:1, make the mixture and carry out ball milling in a ball mill for 1.5 hours, and pass through a 100-mesh sieve;

[0033] (2) Add coal tar of 0.125 times the mass of the mixed material to the mixed material after sieving, and press to form after stirring evenly to obtain an adsorbent blank;

[0034] (3) Preliminarily activate the adsorbent blank in a closed environment at a temperature of 850° C., and measure the pressure of the closed environment at the same time until the pressure in the closed environment is stable, and obtain the initially activated adsorbent matrix;

[0035] (4) Immediately transf...

Embodiment 2

[0039] A kind of oil stain adsorbent, in parts by weight, mainly comprises:

[0040] 1 part of modified activated carbon, 2 parts of modified chitosan;

[0041] A kind of preparation of oil stain adsorbent, described oil stain adsorbent preparation method is:

[0042] (1) Mix the carbonaceous material and the calcium-aluminum hydrotalcite evenly according to the mass ratio of 10:1, make a mixture and carry out ball milling in a ball mill for 3 hours, and pass through a 100-mesh sieve;

[0043] (2) Add coal tar of 0.1 times the mass of the mixture to the sieved mixture, stir evenly and press to form an adsorbent blank;

[0044] (3) Preliminarily activate the adsorbent blank in a closed environment at a temperature of 1100° C., and measure the pressure of the closed environment at the same time until the pressure in the closed environment is stable, and obtain the initially activated adsorbent matrix;

[0045] (4) Immediately transfer the adsorbent matrix to a potassium carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com