Method for improving strength and conductivity matching of copper-based composite material based on in-situ reaction

A copper-based composite material, in-situ reaction technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problem of the difficulty of matching the conductivity and strong plasticity of copper-based composite materials, low interface bonding strength, and poor dispersion problems, to achieve the effect of improving the interface bonding ability, improving the interface wettability, and improving the interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

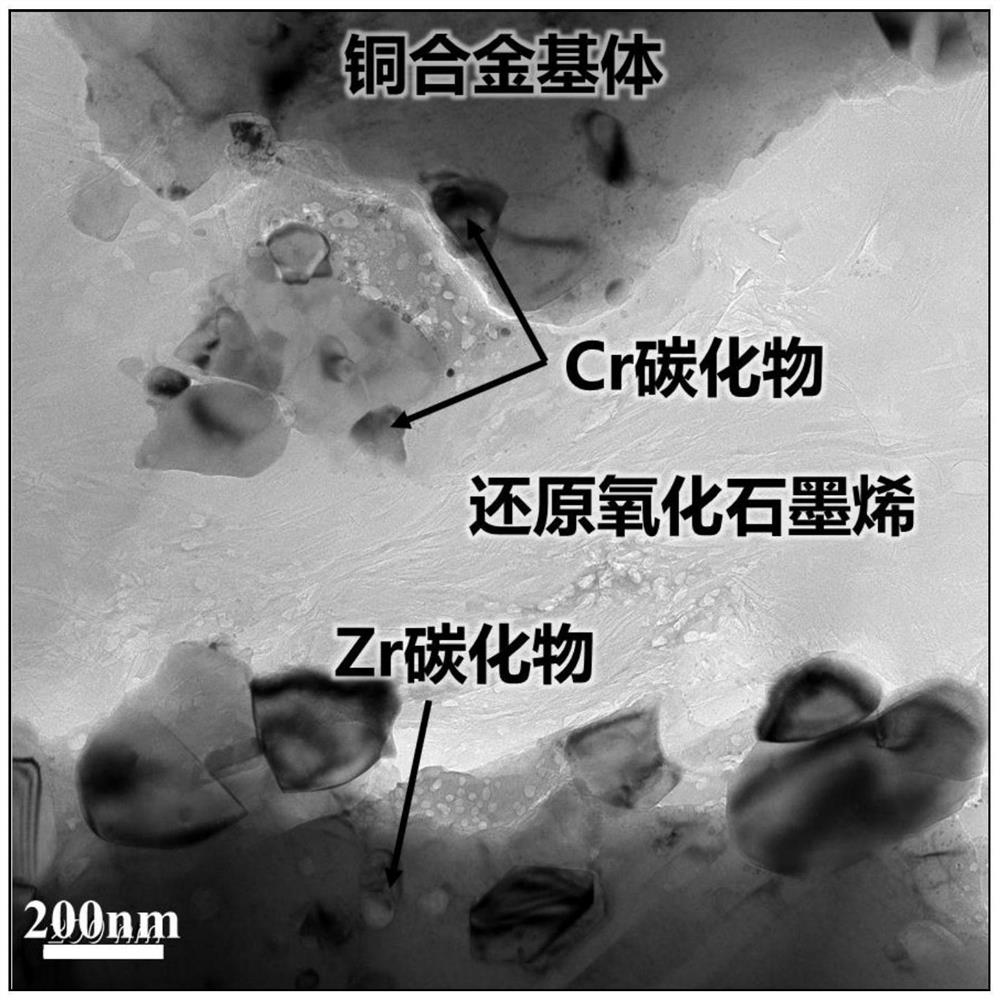

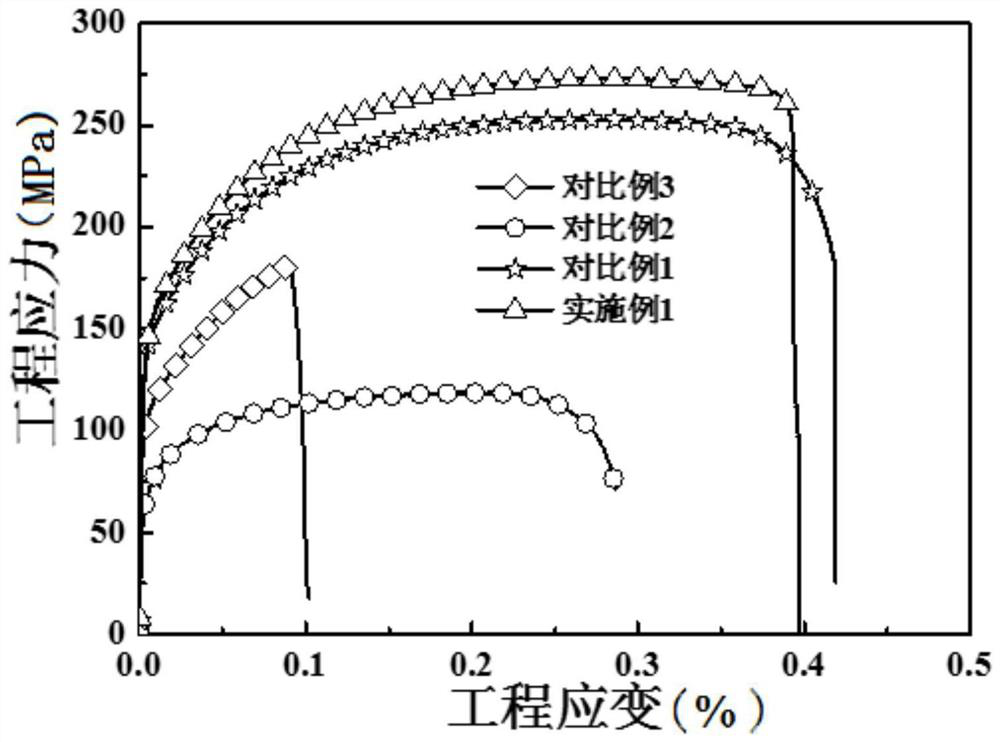

[0024] The preparation process of the copper matrix composite material of the present embodiment comprises the following steps:

[0025] Step 1. Weigh 0.3g of graphene oxide powder and 99.7g of CuCrZr alloy powder, wherein the graphene oxide powder is a nano-powder prepared by Hummers method, and the CuCrZr alloy powder is a 20 μm powder prepared by gas atomization method. The raw material powder is ground on the QM-3SP2 planetary ball mill, and the grinding speed is set to 300r / min. The grinding medium used in the grinding process is stainless steel grinding balls. Among them, 300g of stainless steel grinding balls with a diameter of 8mm and stainless steel grinding balls with a diameter of 5mm 100 g of grinding balls, 100 g of stainless steel grinding balls with a diameter of 2 mm, after grinding for 8 hours, a mixed powder is obtained;

[0026] Step 2. Plasma sintering the mixed powder obtained in step 1. The sintering temperature of plasma sintering is 900° C., the holding...

Embodiment 2

[0035] The preparation process of the copper matrix composite material of the present embodiment comprises the following steps:

[0036] Step 1. Weigh 0.1g of graphene oxide powder and 99.9g of CuCr alloy powder, wherein the graphene oxide powder is a nano-powder prepared by Hummers method, and the CuCr alloy powder is a 10 μm powder prepared by gas atomization method. The raw material powder is ground on the QM-3SP2 planetary ball mill, and the grinding speed is set to 350r / min. The grinding medium used in the grinding process is stainless steel grinding balls. Among them, 300g of stainless steel grinding balls with a diameter of 8mm and stainless steel grinding balls with a diameter of 5mm 100g of grinding balls, 100g of stainless steel grinding balls with a diameter of 2mm, to obtain mixed powder;

[0037] Step 2. Plasma sintering the mixed powder obtained in step 1. The sintering temperature of plasma sintering is 1000° C., the holding time is 20 minutes, the pressure is 1...

Embodiment 3

[0039] The preparation process of the copper matrix composite material of the present embodiment comprises the following steps:

[0040] Step 1. Weigh 10.0g of graphene oxide powder and 990.0g of CuCrZr alloy powder, wherein the graphene oxide powder is a nano-powder prepared by the Hummers method, and the CuCrZr alloy powder is a 60 μm powder prepared by a gas atomization method. The raw material powder is ground on the QM-3SP2 planetary ball mill, and the grinding speed is set to 250r / min. The grinding medium used in the grinding process is stainless steel grinding balls. Among them, 300g of stainless steel grinding balls with a diameter of 8mm, and stainless steel grinding balls with a diameter of 5mm 100 g of grinding balls, 100 g of stainless steel grinding balls with a diameter of 2 mm, after grinding for 5 hours, a mixed powder is obtained;

[0041] Step 2: Perform plasma sintering on the mixed powder obtained in step 1. The sintering temperature of plasma sintering is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com