Processing method of cooked rice containing gamma-aminobutyric acid

A technology of aminobutyric acid and processing method, applied in chemical instruments and methods, dissolution, food ingredients, etc., can solve the problems of single taste, low processing efficiency, poor appearance, etc., to meet the requirements of processing and use, and to process quickly , the effect of various tastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Propose a kind of processing method containing the rice rice of gamma-aminobutyric acid in this implementation, comprise the steps:

[0034] S1: Carry out enzymatic hydrolysis of brown rice, soak the brown rice in the enzymatic hydrolysis solution, the soaking time is 30 minutes, the soaking temperature is 30°C, and the pH of the enzymatic hydrolysis solution is adjusted to 4 with fruit acid, and the enzymatic hydrolysis solution is made of fiber Prepared by sudase, pectinase, amylase and water, and the fruit acid is one of citric acid, gluconic acid, malic acid, mandelic acid and lactic acid;

[0035] S2: Washing and lightly cooking the ingredients, the ingredients include one or more of black rice, glutinous rice, red japonica rice, oat rice, millet, large yellow rice, millet, corn grits, red bean, black bean, kidney bean, and mung bean;

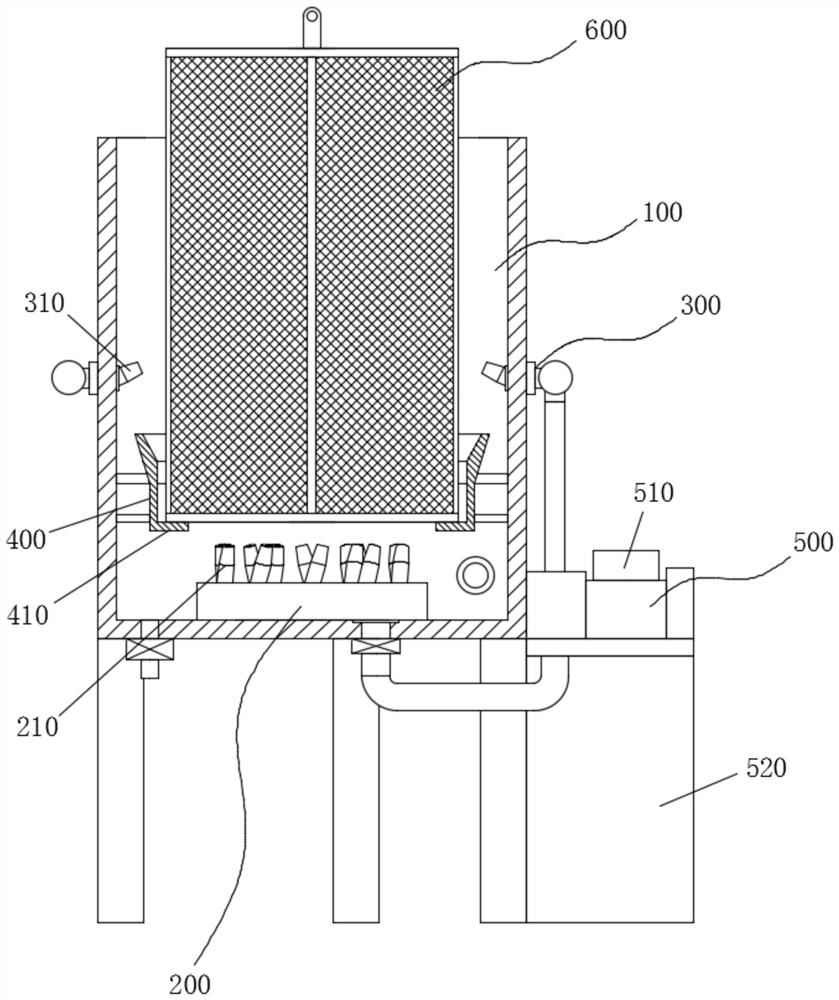

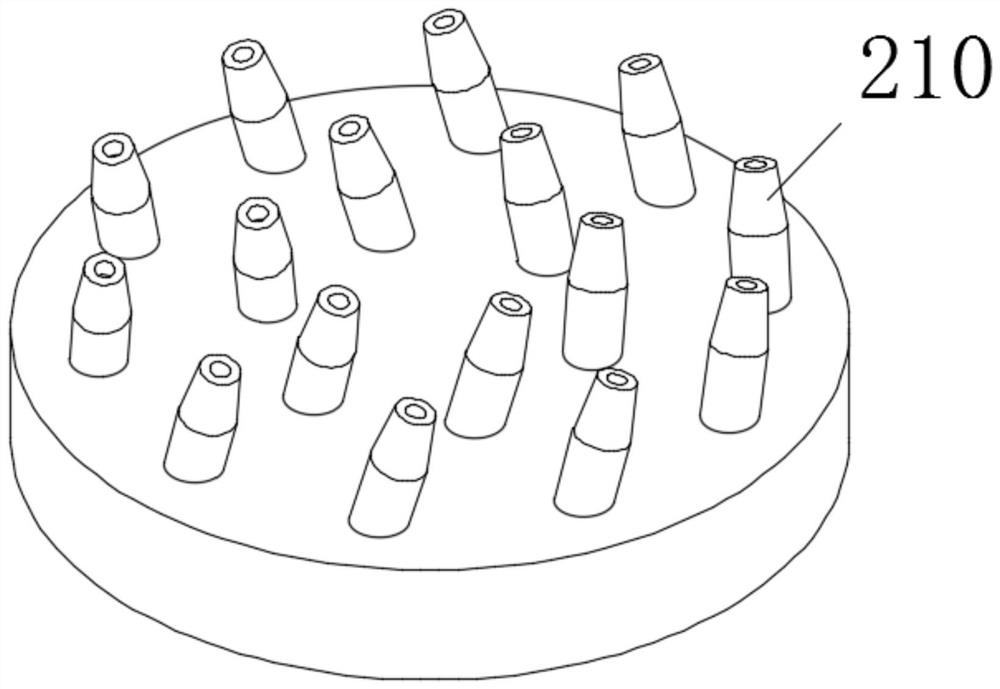

[0036] S3: Take out the soaked brown rice, wash it with water, and use the mixing mechanism to mix the brown rice and ingredients ...

Embodiment 2

[0041] Propose a kind of processing method containing the rice rice of gamma-aminobutyric acid in the present embodiment, comprise the steps:

[0042] S1: Carry out enzymatic hydrolysis of brown rice, soak the brown rice in the enzymatic hydrolysis solution, the ratio of soaking material to liquid is 1:4.5, the soaking time is 45min, the soaking temperature is 45°C, the pH of the enzymatic hydrolysis solution is adjusted to 5 with fruit acid, and the enzymatic hydrolysis solution is made of fiber Prepared by sudase, pectinase, amylase and water, and the fruit acid is one of citric acid, gluconic acid, malic acid, mandelic acid and lactic acid;

[0043] S2: Washing and lightly cooking the ingredients, the ingredients include one or more of black rice, glutinous rice, red japonica rice, oat rice, millet, large yellow rice, millet, corn grits, red bean, black bean, kidney bean, and mung bean;

[0044] S3: Take out the soaked brown rice, wash it with water, and use the mixing mech...

Embodiment 3

[0049] In this a kind of processing method of rice containing γ-aminobutyric acid, it is characterized in that, comprises the steps:

[0050] S1: Carry out enzymatic hydrolysis of brown rice, soak the brown rice in the enzymatic hydrolysis solution, the soaking material liquid ratio is 1:6, the soaking time is 60min, the soaking temperature is 60°C, the pH of the enzymatic hydrolysis solution is adjusted to 6 with fruit acid, and the enzymatic hydrolysis solution is made of fiber Prepared by sudase, pectinase, amylase and water, and the fruit acid is one of citric acid, gluconic acid, malic acid, mandelic acid and lactic acid;

[0051] S2: Washing and lightly cooking the ingredients, the ingredients include one or more of black rice, glutinous rice, red japonica rice, oat rice, millet, large yellow rice, millet, corn grits, red bean, black bean, kidney bean, and mung bean;

[0052] S3: Take out the soaked brown rice, wash it with water, and use the mixing mechanism to mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com