A method for constructing a flexible metal negative electrode using a positive electrode material as an interface layer

A cathode material, flexible metal technology, applied in electrode collector coatings, structural parts, battery electrodes, etc., can solve the problems of many side reactions, poor mechanical stability, poor safety, etc., to achieve good bendability, cycle good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

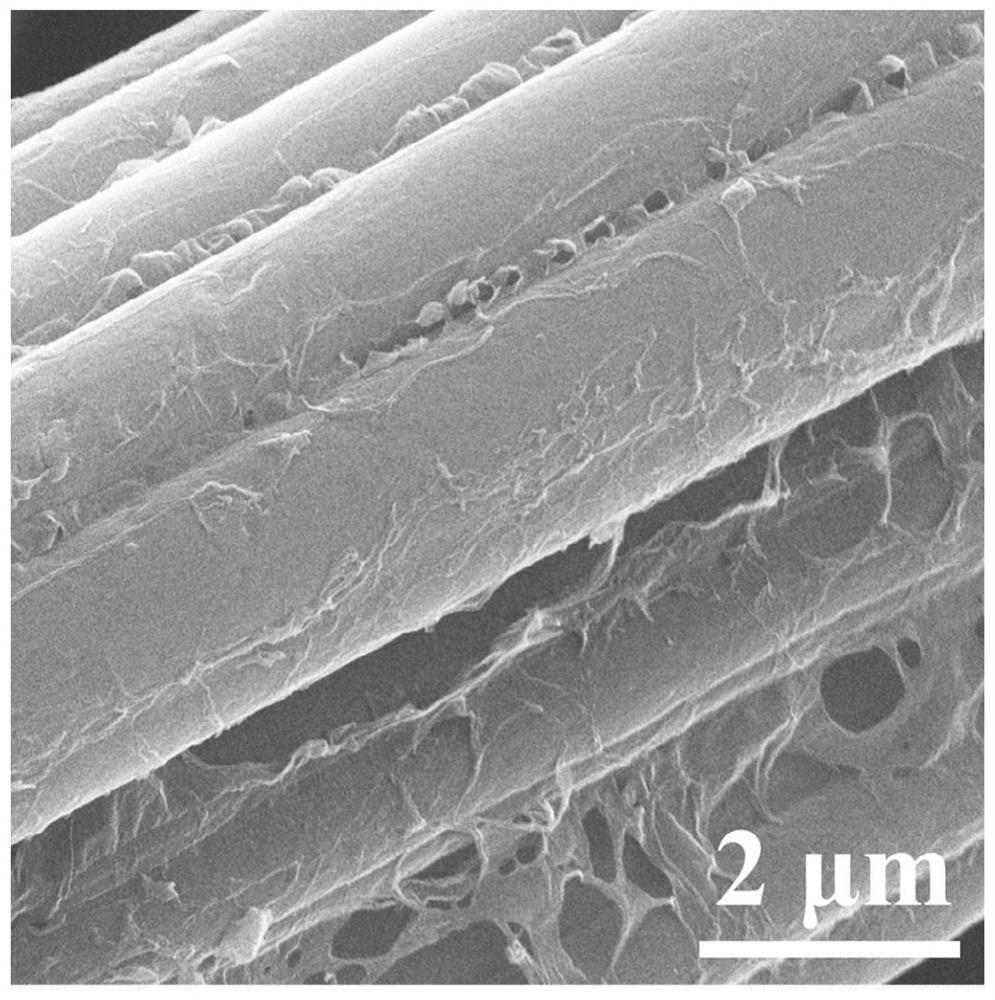

[0025] Deposition of metallic zinc on the surface of carbon cloth modified vanadium oxide cathode film:

[0026] a: prepare the 0.02M ammonium metavanadate solution of 100mL, transfer to the reaction kettle of polytetrafluoroethylene after ultrasonic dispersion;

[0027] b: carbon with a size of 3*5 is arranged in the above-mentioned ammonium metavanadate solution, then, after being continuously heated in an oven at 160 ° C for 10 min, it is naturally cooled, and then washed with deionized water and dried;

[0028] c: Assemble the sample obtained in step b and the zinc sheet into a half-cell, and after standing for 12 hours, use the blue electric system to deposit metal zinc, and the deposition amount is 6mAh cm –2 .

Embodiment 2

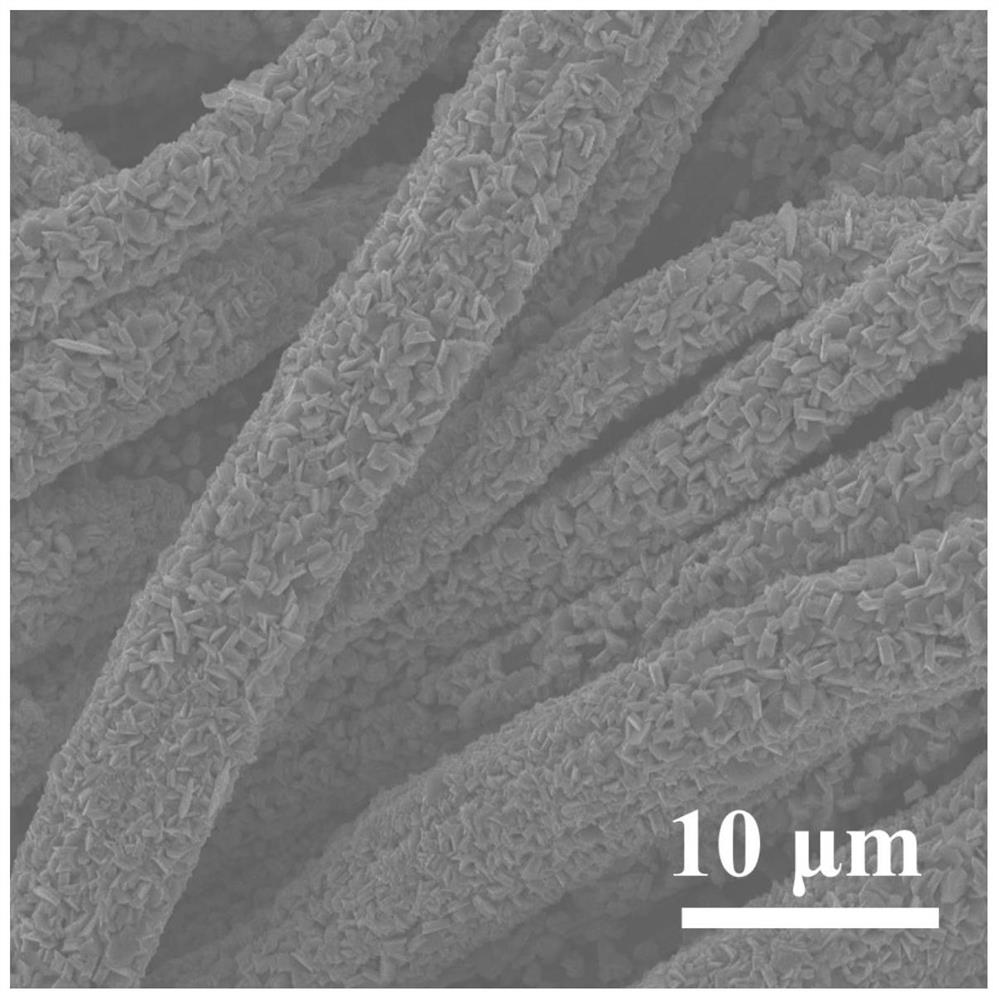

[0030] Deposition of metallic zinc on the surface of carbon cloth modified manganese oxide cathode film:

[0031] a: prepare the 0.02M potassium permanganate solution of 100mL, transfer to the reaction kettle of polytetrafluoroethylene after ultrasonic dispersion;

[0032] b: commercial carbon with a size of 3*5 is arranged in the above potassium permanganate solution, then, after being continuously heated in an oven at 180 ° C for 10 min, it is naturally cooled, and then washed with deionized water and dried;

[0033] c: Assemble the sample obtained in step b and the zinc sheet into a half-cell, and after standing for 12 hours, use the blue electric system to deposit metal zinc, and the deposition amount is 6mAh cm –2 .

Embodiment 3

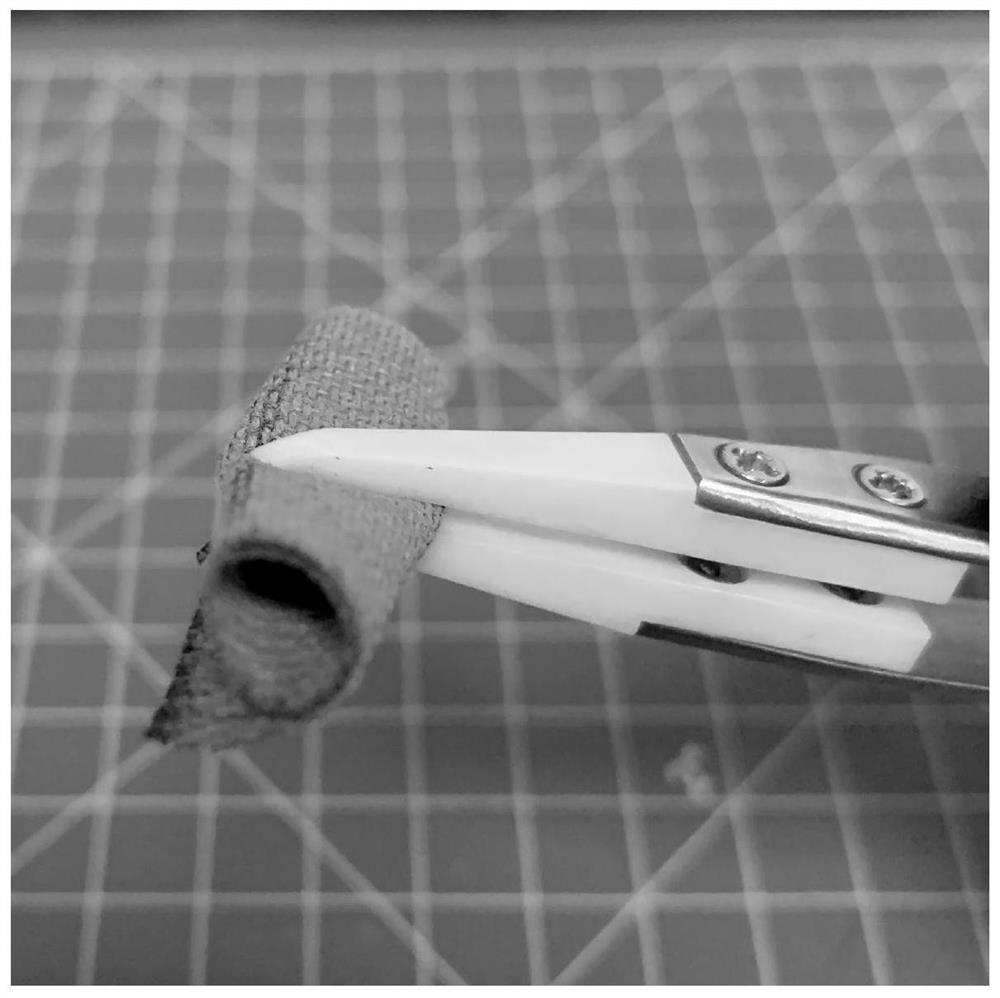

[0035] Deposition of lithium metal on the carbon cloth surface modified lithium cobalt oxide cathode film after delithiation:

[0036] a: The lithium cobalt oxide was sprayed on the carbon cloth substrate, sintered at a high temperature of 800°C, and cooled naturally;

[0037] b: then the above-mentioned material and graphite are assembled into a battery, and the charging process is carried out after standing for 12h, and lithium ions are removed, and then the battery is disassembled, and the electrode sheet is taken out for washing and drying;

[0038] c: Assemble the sample obtained in step b and the lithium sheet into a half-cell, and after standing for 12 hours, use the blue electric system to deposit lithium metal, and the deposition amount is 6mAh cm –2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com