Scandium bulk phase doped and lithium chromium titanium phosphate modified positive electrode material precursor and preparation method thereof

A technology of titanium chromium lithium phosphate and positive electrode materials, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of high production cost, high energy consumption, uneven shape of precursors, etc., and achieve narrow particle size distribution , the effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

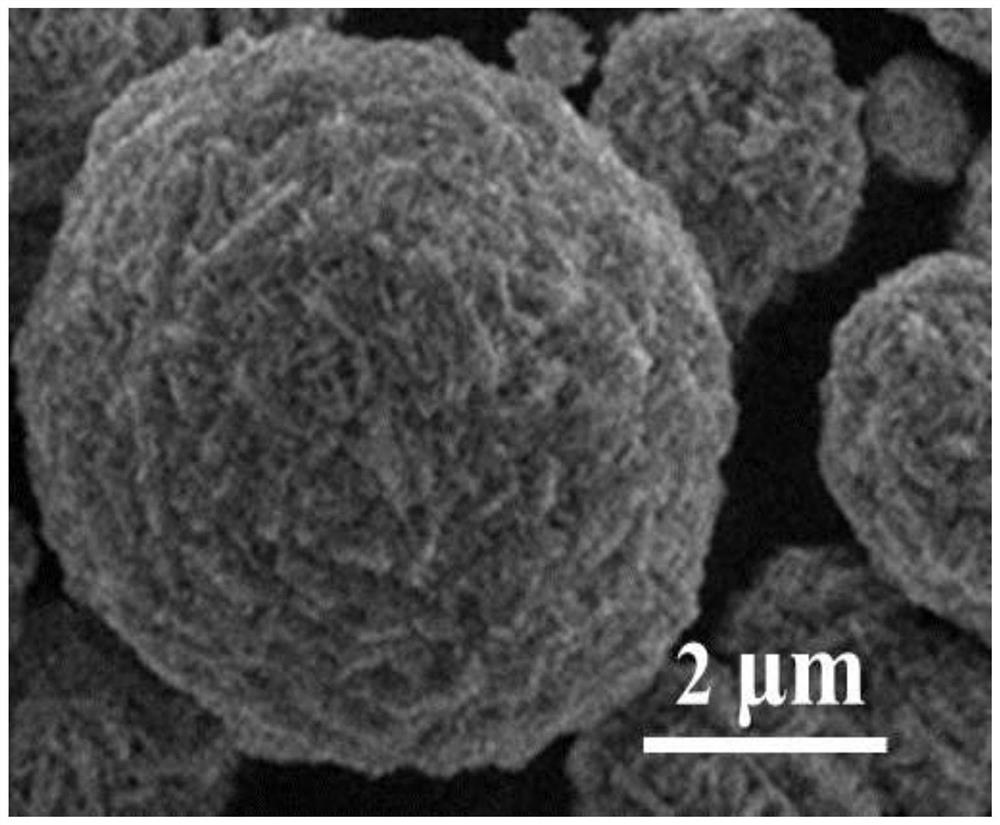

Embodiment 1

[0040] In this example, the chemical formula of scandium bulk phase doping and titanium chromium lithium phosphate modified positive electrode material precursor is Ni 0.92 co 0.04 mn 0.04 sc 0.001 (OH) 2 0.01 Li 2 CrTi(PO 4 ) 3 .

[0041] In this embodiment, the preparation method of scandium body phase doping and titanium chromium lithium phosphate modified positive electrode material precursor includes the following steps:

[0042] (1) Add 0.46L 2moL / L NiSO 4 ·6H 2 O solution, 0.02L 2moL / L CoSO 4 ·7H 2 O solution, 0.02L2moL / L MnSO 4 ·H 2 O solution and 0.0005L 2moL / L Sc(NO 3 ) 3 The solution is mixed evenly to obtain a mixed solution;

[0043] (2) Add 4L 6mol / L NH to the mixed solution obtained in step (1) 3 ·H 2 O solution and 0.34L 6mol / LNaOH solution were stirred continuously, the pH value of the reaction system was controlled to be 10.5, the concentration of ammonia water was 2mol / L, and a co-precipitation reaction was carried out for 40 hours to obtain...

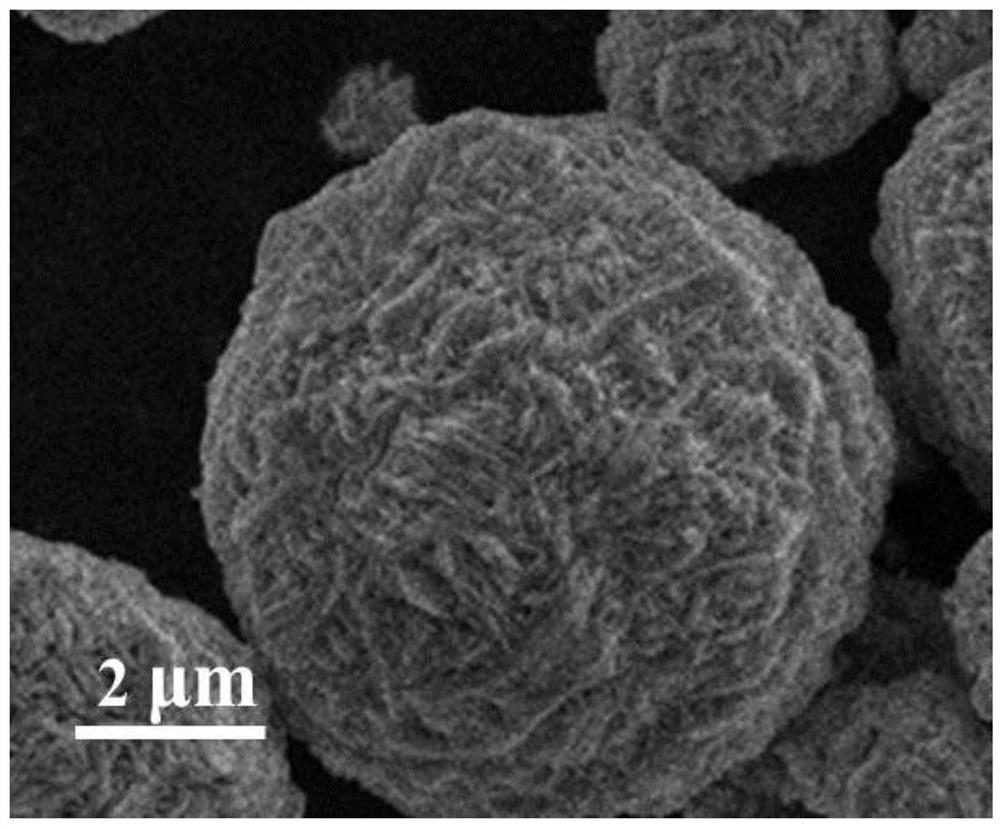

Embodiment 2

[0049] In this example, the chemical formula of scandium bulk phase doping and titanium chromium lithium phosphate modified positive electrode material precursor is Ni 0.92 co 0.04 mn 0.04 sc 0.002 (OH) 2 0.02Li 2 CrTi(PO 4 ) 3 .

[0050] In this embodiment, the preparation method of scandium body phase doping and titanium chromium lithium phosphate modified positive electrode material precursor includes the following steps:

[0051] (1) Add 0.31L 3moL / L NiSO 4 ·6H 2 O solution, 0.013L 3moL / L CoSO 4 ·7H 2 O solution, 0.013L3moL / L MnSO 4 ·H 2 O solution and 0.0006L 3moL / L Sc(NO 3 ) 3 The solution is mixed evenly to obtain a mixed solution;

[0052] (2) Add 4.5L 6.5mol / L NH 3 ·H 2 O solution and 0.27L7.5mol / L NaOH solution were stirred continuously, the pH value of the reaction system was controlled to be 11.0, the concentration of ammonia water was 2.8mol / L, and a co-precipitation reaction was carried out for 40 hours to obtain a solid-liquid mixture;

[0053]...

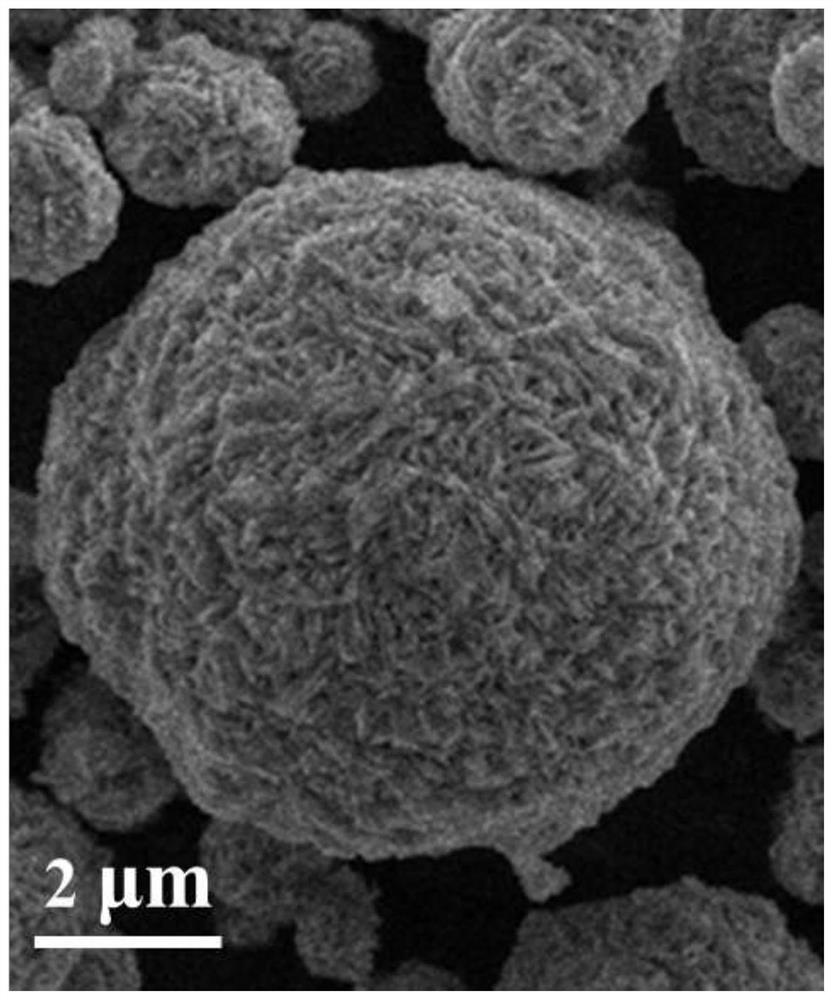

Embodiment 3

[0058] In this example, the chemical formula of scandium bulk phase doping and titanium chromium lithium phosphate modified positive electrode material precursor is Ni 0.92 co 0.04 mn 0.04 sc 0.003 (OH) 2 0.03 Li 2 CrTi(PO 4 ) 3 .

[0059] In this embodiment, the preparation method of scandium body phase doping and titanium chromium lithium phosphate modified positive electrode material precursor includes the following steps:

[0060] (1) Add 0.31L 3moL / L NiSO 4 ·6H 2 O solution, 0.013L 3moL / L CoSO 4 ·7H 2 O solution, 0.013L3moL / L MnSO 4 ·H 2 O solution and 0.001L 3moL / L Sc(NO 3 ) 3 The solution is mixed evenly to obtain a mixed solution;

[0061] (2) Add 4L 7mol / L NH to the mixed solution obtained in step (1) 3 ·H 2 O solution and 0.286L 7mol / LNaOH solution were stirred continuously, the pH value of the reaction system was controlled to be 11.0, the concentration of ammonia water was 2.5mol / L, and a coprecipitation reaction was carried out for 40 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com