Gelatin-based biocompatible polymer dressing

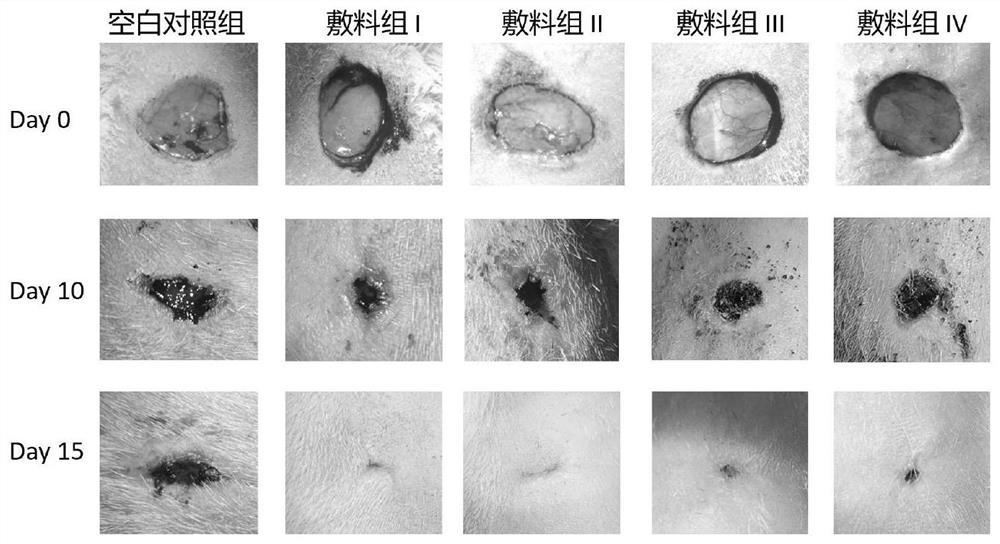

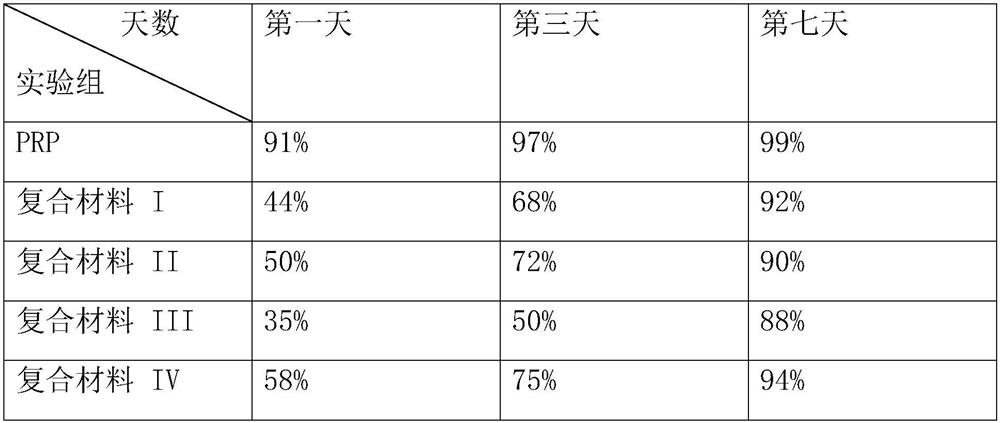

A biocompatible, polymer technology, applied in medical science, bandages, etc., can solve the problems of low wound healing promotion effect, synthetic hydrocolloid dressings unable to provide good support for wound cell migration, limited biological inertness of materials, etc. Achieving the effect of uniform and delicate texture, promoting the healing of chronic skin wounds, and steadily healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 dressing

[0039] 10 grams of hyaluronic acid (weight average molecular weight: 400 kDa) was weighed and dissolved in 500 ml of deionized water to obtain a hyaluronic acid solution with a w / v concentration of 2.0%. Weigh 5.35 g of sodium periodate, add it to the hyaluronic acid solution, stir at room temperature in the dark for 24 hours, add 5 ml of ethylene glycol and continue stirring for 1 hour to terminate the reaction. The obtained solution was dialyzed in deionized water for five days to obtain 860 ml of oxidized hyaluronic acid solution, and the concentration of oxidized hyaluronic acid in the obtained solution was determined to be 8.6 mg / mL by solid content detection.

[0040] 10 g of gelatin was weighed and dissolved in 100 ml of 0.1 M (0.1 mol / L) acetic acid solution to obtain a gelatin solution with a w / v concentration of 10%. Take 232 ml of the above-mentioned oxidized hyaluronic acid solution, add it dropwise to the gelatin ...

Embodiment 2

[0041] The preparation of embodiment 2 dressings

[0042] 4 grams of starch (weight average molecular weight: 60 kDa) was weighed and dissolved in 100 ml of deionized water to obtain a starch solution with a w / v concentration of 4.0%. Weigh 5.35 g of sodium periodate, add it into the starch solution, and stir for 12 hours at room temperature in the dark, then add 5 ml of ethylene glycol and continue stirring for 1 hour to terminate the reaction. The obtained solution was dialyzed in deionized water for five days to obtain 153 ml of oxidized starch solution, and the concentration of oxidized starch in the obtained solution was determined to be 22.9 mg / mL by solid content detection.

[0043] 10 g of gelatin was weighed and dissolved in 100 ml of 0.1 M acetic acid solution to obtain a gelatin solution with a w / v concentration of 10%. Take 87 ml of the above-mentioned oxidized starch solution, add it dropwise into the gelatin solution, and stir until a uniform solution is obtaine...

Embodiment 3

[0044] The preparation of embodiment 3 dressings

[0045] Weighed 11.9 grams of chondroitin sulfate (weight average molecular weight: 100 kDa), dissolved in 100 ml of deionized water to obtain a chondroitin sulfate solution with a w / v concentration of 11.9%. Weigh 5.35 g of sodium periodate, add it into the chondroitin sulfate solution, stir at room temperature in the dark for 10 hours, add 5 ml of ethylene glycol and continue stirring for 1 hour to terminate the reaction. The obtained solution was dialyzed in deionized water for five days to obtain 348 ml of oxidized chondroitin sulfate solution, and the concentration of oxidized chondroitin sulfate in the obtained solution was determined to be 28.7 mg / mL by solid content detection.

[0046] 10 g of gelatin was weighed and dissolved in 1000 ml of 0.1 M acetic acid solution to obtain a gelatin solution with a w / v concentration of 1.0%. Take 70 ml of the above-mentioned oxidized chondroitin sulfate solution, add it dropwise to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com