Preparation method and application of multifunctional laccase-like CuNi/CoMoO4

A multifunctional, laccase technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical analysis using catalysis, etc., to achieve the effect of increasing specific surface area, good catalytic activity, and good substrate versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

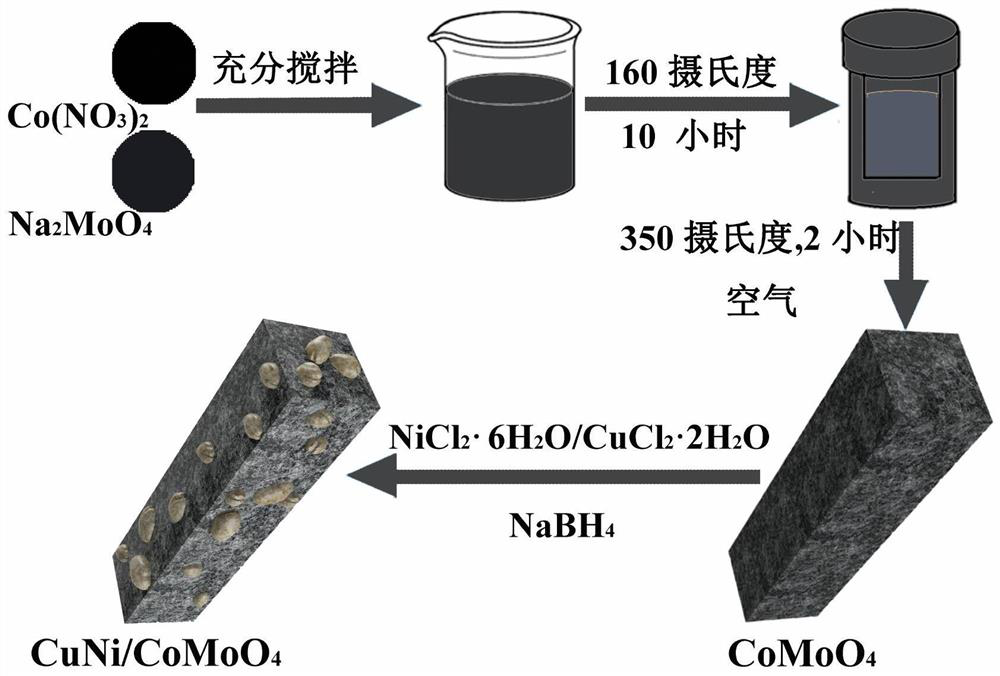

[0075] A CuNi / CoMoO as a multifunctional laccase-like 4 A preparation method comprising the steps of:

[0076] S1: CoMoO 4 preparation of

[0077] Na 2 MoO 4 2H 2 O and Co(NO 3 ) 2 ·6H 2 O was fully stirred and dissolved in deionized water, and then reacted in an autoclave; after centrifugation, it was washed three times with deionized water and ethanol to obtain a precursor; after that, it was vacuum-dried, and the precursor was calcined to obtain CoMoO 4 ;

[0078] S2: CuNi / CoMoO 4 preparation of

[0079] CuCl 2 2H 2 O, NiCl 2 ·6H 2 O and prepared CoMoO 4 Dissolve in deionized water and stir; then add NaHB 4 Stirring, followed by washing with deionized water and ethanol, followed by vacuum drying, yielded CuNi / CoMoO 4 .

[0080] In step S1: Na 2 MoO 4 2H 2 O and Co(NO 3 ) 2 ·6H 2 The amount ratio of O is the molar ratio, and the molar ratio is 1:1; the reaction conditions in the autoclave are: the reaction temperature is 155-165°C, the reaction time i...

Embodiment

[0090] (1) CuNi / CoMoO 4 Preparation example

[0091] S1: CoMoO 4 preparation of

[0092] 1mmolNa 2 MoO4·2H 2 O and 1mmolCo(NO 3 ) 2 ·6H 2 O was fully stirred and dissolved in 40mL deionized water, and then reacted in a 50mL autoclave at 160°C for 10h; after centrifugation, washed three times with deionized water and ethanol to obtain the precursor; then vacuum-dried at 80°C, the precursor Calcined at 350 °C for 2 h in the air to obtain CoMoO 4 .

[0093] S2: CuNi / CoMoO 4 preparation of

[0094] Weigh 0.0768g of CuCl at a molar ratio of 3:1 2 2H 2 O, 0.0387g NiCl 2 ·6H 2 0.04g of CoMoO prepared by O and S1 4 Dissolve in 20mL deionized water and stir for 3h, then add 10mL, 10mg / mL NaHB 4 Stirring for 5 h, followed by washing with deionized water and ethanol, and vacuum drying at 80 °C, CuNi / CoMoO with a Cu / Ni molar ratio of about 3:1 was obtained 4 .

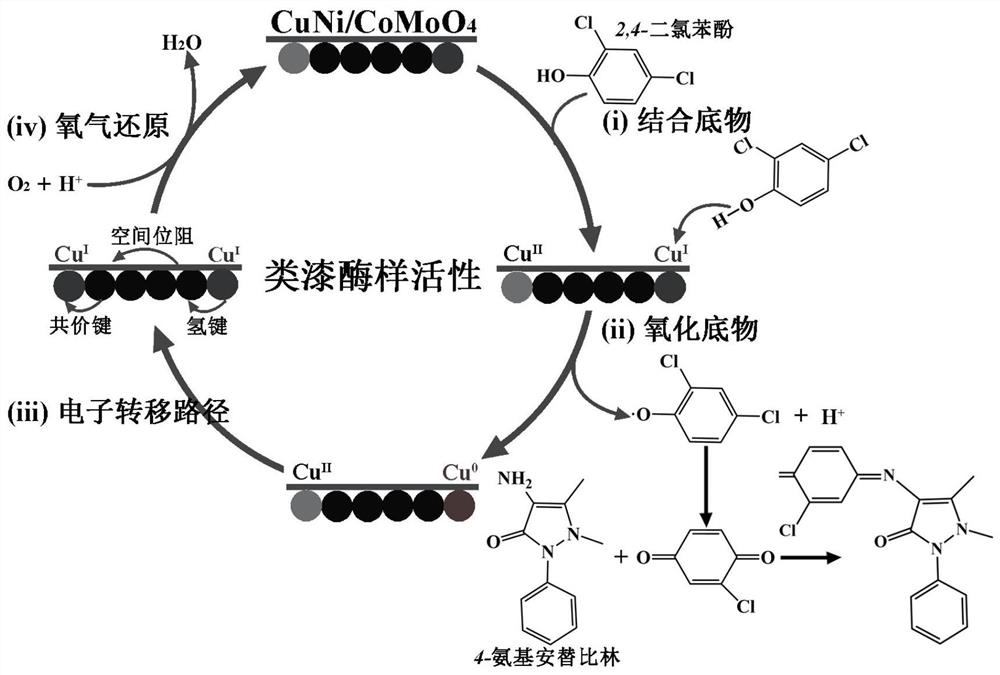

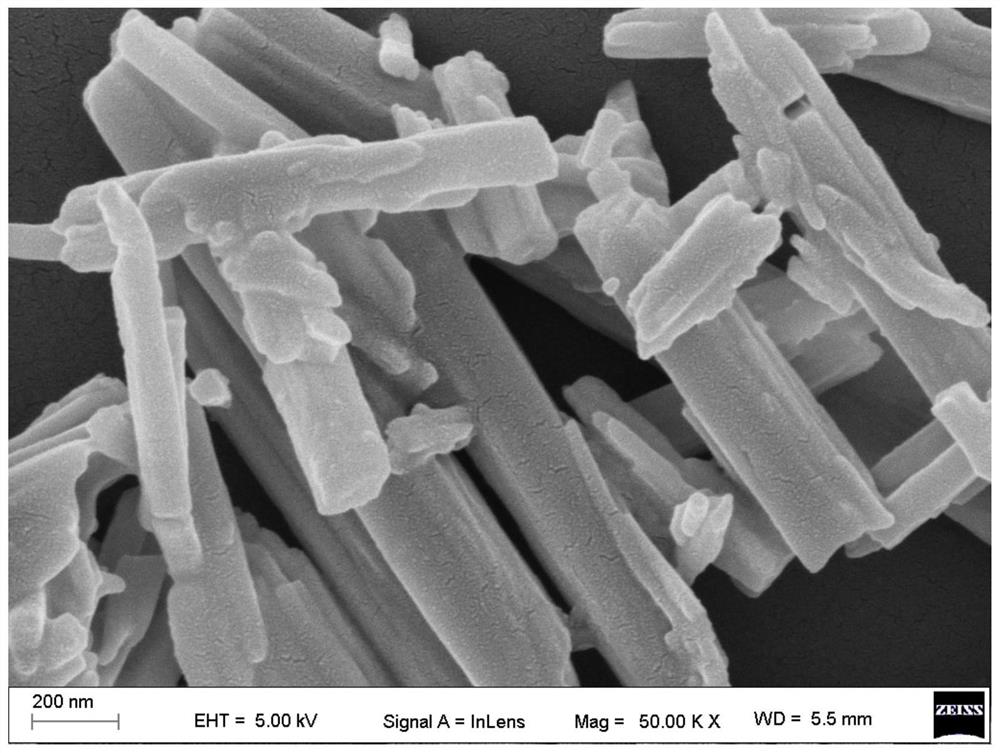

[0095] Such as Figure 1 to Figure 4 As shown, CuNi / CoMoO was prepared by a combined method of hydrothermal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com