Cuttlefish melanin-based nano-silver composite material as well as preparation method and catalytic application thereof

A composite material and melanin-based technology are applied in the field of squid melanin-based nano-silver composite materials and their preparation, which can solve the problems of complex synthesis process, complicated and expensive, and high energy consumption, and achieve stable catalytic performance, good catalytic performance, and difficulty in agglomeration. or shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

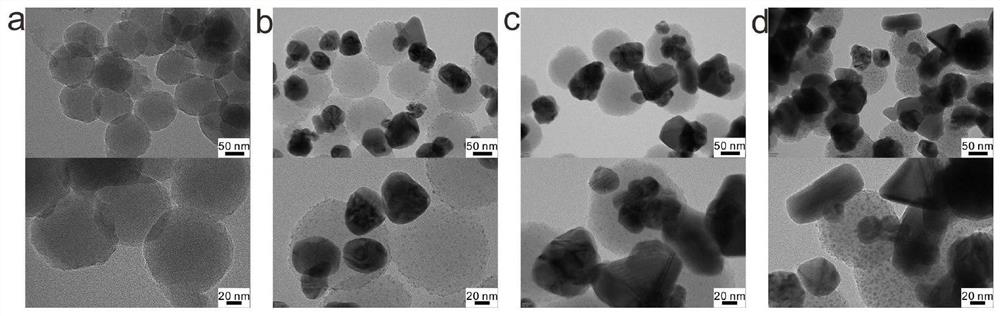

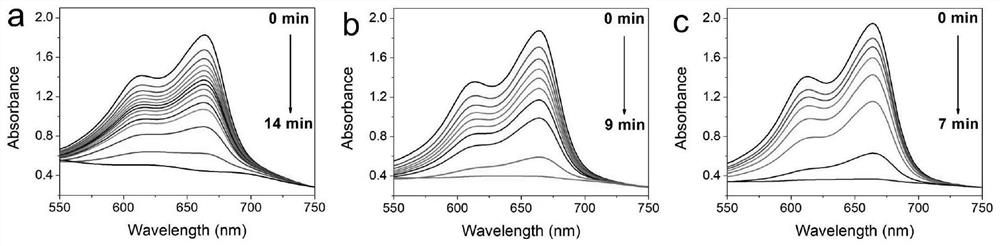

Embodiment 1

[0023] A squid melanin-based nano-silver composite material, the preparation method of which comprises the steps of:

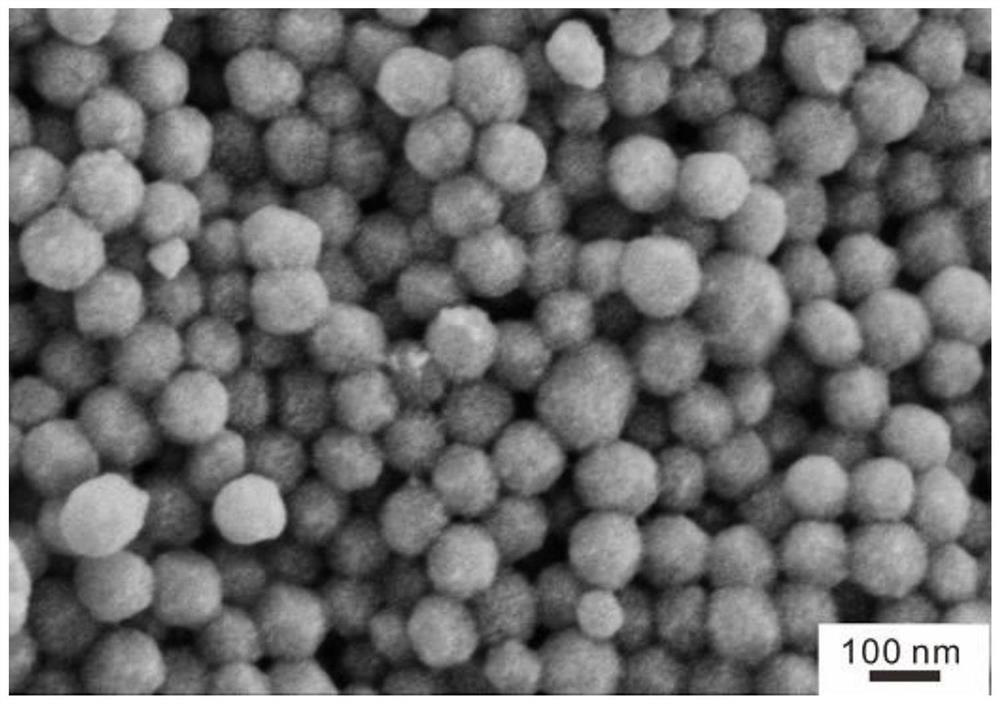

[0024] S1. Preparation of squid melanin dispersion: take squid ink sac, cut and squeeze out the ink, add 2 times the volume of deionized water to soak for 10 hours, centrifuge at 10000rmp, separate solid and liquid, and remove the filtrate and its soluble components , the remaining solid was vacuumized to -0.08MPa at 45°C, and dried for 24 hours to obtain squid melanin powder. Then take 0.2000g of squid melanin powder and add it to 9.8265g of deionized water, ultrasonically oscillate until the dispersion is uniform, and let it stand for precipitation 10-14h, slowly absorb the upper layer liquid (the mass of the precipitated part after drying is about 0.0265g), that is, a squid melanin dispersion with a solid content of about 1.735%, and set aside;

[0025] S2. Composite material preparation: Put 1g of PVP powder, 30mL of deionized water and 4g of S1 squid mela...

Embodiment 2

[0027] A squid melanin-based nano-silver composite material, the preparation method of which comprises the steps of:

[0028] S1. Preparation of squid melanin dispersion: take squid ink sac, cut and squeeze out the ink, add 2 times the volume of deionized water to soak for 10 hours, centrifuge at 10000rmp, separate solid and liquid, and remove the filtrate and its soluble components , the remaining solid was vacuumized to -0.08MPa at 45°C, and dried for 24 hours to obtain squid melanin powder. Then take 0.2000g of squid melanin powder and add it to 9.8265g of deionized water, ultrasonically oscillate until the dispersion is uniform, and let it stand for precipitation 10-14h, slowly absorb the upper layer liquid (the mass of the precipitated part after drying is about 0.0285g), that is, a squid melanin dispersion with a solid content of about 1.715%, and set aside;

[0029] S2. Composite material preparation: Put 1g of PVP powder, 30mL of deionized water and 4g of S1 squid mela...

Embodiment 3

[0031] A squid melanin-based nano-silver composite material, the preparation method of which comprises the steps of:

[0032] S1. Preparation of squid melanin dispersion: take squid ink sac, cut and squeeze out the ink, add 2 times the volume of deionized water to soak for 10 hours, centrifuge at 10000rmp, separate solid and liquid, and remove the filtrate and its soluble components , the remaining solid was vacuumized to -0.08MPa at 45°C, and dried for 24 hours to obtain squid melanin powder. Then take 0.2000g of squid melanin powder and add it to 9.8265g of deionized water, ultrasonically oscillate until the dispersion is uniform, and let it stand for precipitation 10-14h, slowly absorb the upper layer liquid (the mass of the precipitated part after drying is about 0.0305g), that is, a squid melanin dispersion with a solid content of about 1.695%, and set aside;

[0033] S2. Composite material preparation: put PVP powder 1g, deionized water 30mL and S1 squid melanin dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com