Prussian blue and analogue thereof, and defect repair method and application thereof

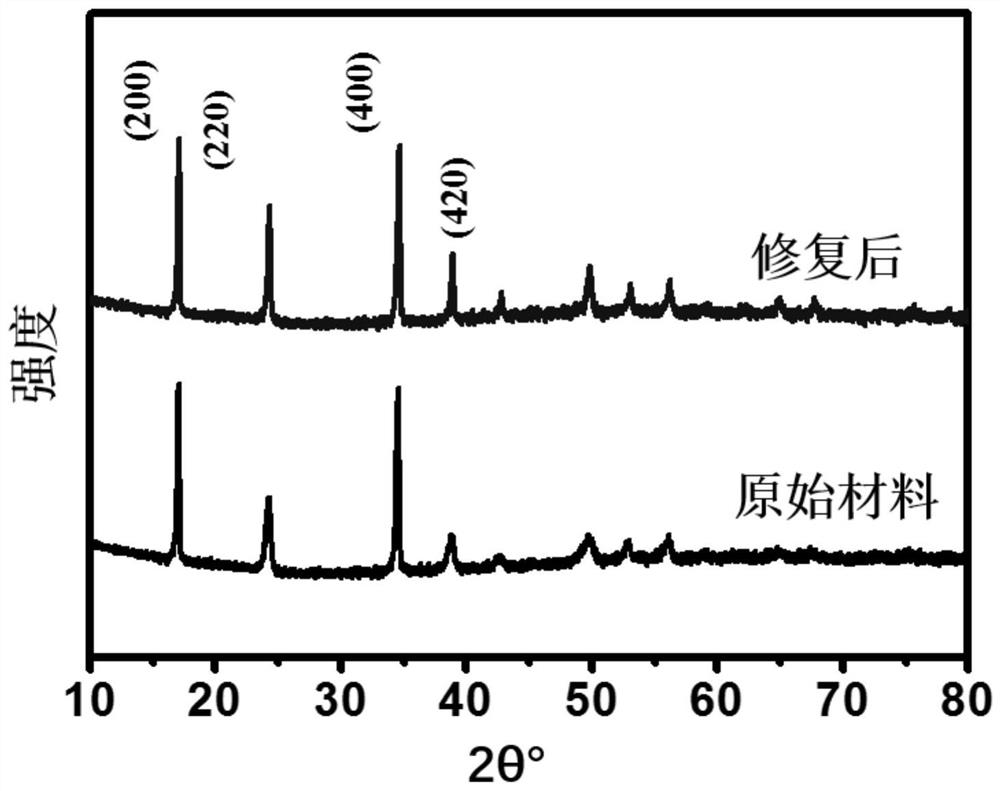

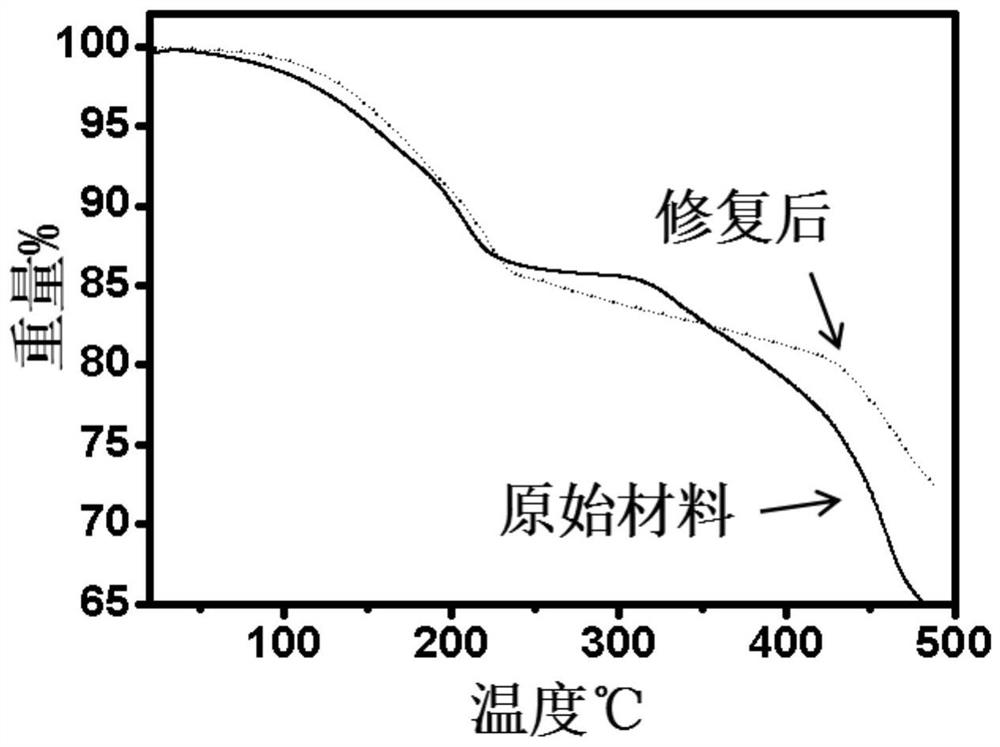

A Prussian blue and defect repairing technology, applied in the direction of ferricyanide, metal cyanide, active material electrodes, etc., can solve the problems of low yield, long reaction time, clogged iron base, etc., and achieve the improvement of charge-discharge specific capacity and cycle The effect of stability improvement and vacancy defect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

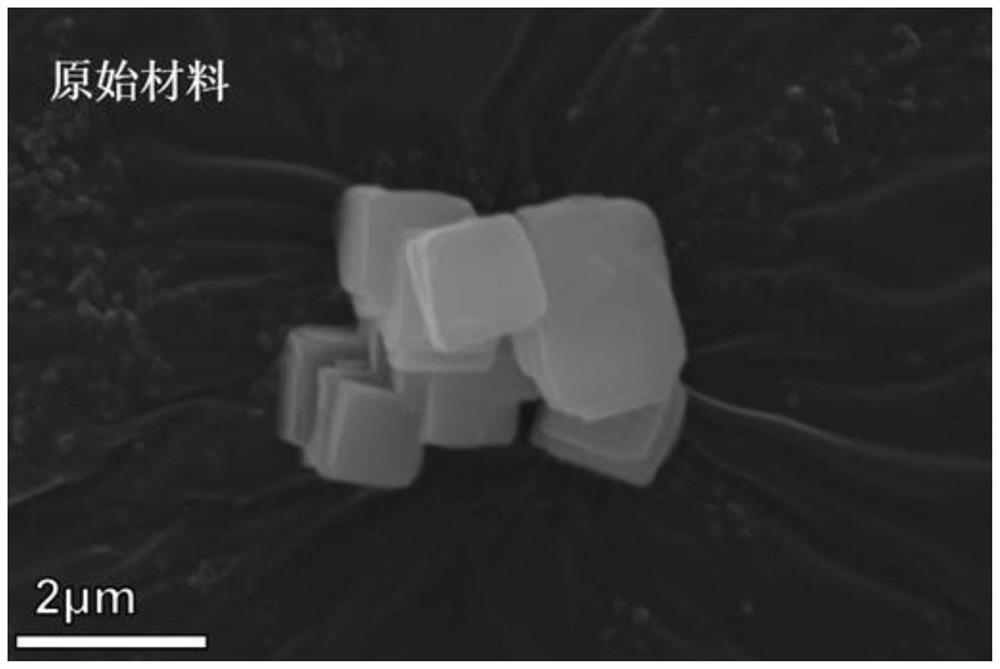

[0033] This embodiment provides a method for repairing defects of Prussian blue and its analogs, the repaired Prussian blue and its analogs obtained through the repair, and using the Prussian blue and its analogs as anode materials for sodium-ion batteries. The method comprises the steps of:

[0034] S1 Add 48.4 grams of sodium ferrocyanide powder with a purity greater than 99.5% into 100 ml of deionized water, and stir at a temperature of 40°C until a nearly saturated yellow solution of sodium ferrocyanide is formed 1;

[0035] S2 prepared the original material of Prussian blue by traditional dual-iron source co-precipitation method. Specifically, 1.112 grams of ferrous sulfate and 20 grams of sodium ferrocyanide were added to 100 milliliters of deionized water to prepare solution A, and then 0.484 grams of sodium ferrocyanide was dissolved in 100 milliliters of deionized water to be solution B. The AB solution was mixed, stirred for 1 hour, and stood at room temperature for...

Embodiment 2

[0044] This embodiment provides a method for repairing defects of Prussian blue and its analogs, the repaired Prussian blue and its analogs obtained through the repair, and using the Prussian blue and its analogs as anode materials for sodium-ion batteries. The method comprises the steps of:

[0045] S1 Add 48.4 grams of sodium ferrocyanide powder with a purity greater than 99.5% into 100 ml of deionized water, and stir at a temperature of 40°C until a nearly saturated yellow solution of sodium ferrocyanide is formed 1;

[0046] S2 prepared the original material of Prussian blue by traditional dual-iron source co-precipitation method. Specifically, 1.112 grams of ferrous sulfate and 20 grams of sodium ferrocyanide were added to 100 milliliters of deionized water to prepare solution A, and then 0.484 grams of sodium ferrocyanide was dissolved in 100 milliliters of deionized water to be solution B. The AB solution was mixed, stirred for 1 hour, and stood at room temperature for...

Embodiment 3

[0052] This embodiment provides a method for repairing defects of Prussian blue and its analogs, the repaired Prussian blue and its analogs obtained through the repair, and using the Prussian blue and its analogs as anode materials for sodium-ion batteries. The method comprises the steps of:

[0053] S1 Add 48.4 grams of sodium ferrocyanide powder with a purity greater than 99.5% into 100 ml of deionized water, and stir at a temperature of 40°C until a nearly saturated yellow solution of sodium ferrocyanide is formed 1;

[0054] S2 uses commercial sodium-free Prussian blue as the raw material, CAS: 14038-43-8, manufacturer: Aladdin, specification: 25 grams;

[0055] S3 Take 0.5 g of the original powder of S2 Prussian blue and add it to solution 1, stir at 40°C for 12 hours and then let it stand for 2 hours to obtain a precipitate;

[0056] S4 collects the precipitate obtained in step S3 by centrifugation, and rinses with deionized water and absolute ethanol for 3 times;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com