Modified fly ash adsorption-UF-RO advanced treatment coking wastewater detection method

A technology of UF-RO and coking wastewater, applied in the detection field of modified fly ash adsorption-UF-RO advanced treatment of coking wastewater, can solve the problems of harsh regeneration conditions, low removal rate and troublesome operation of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Content

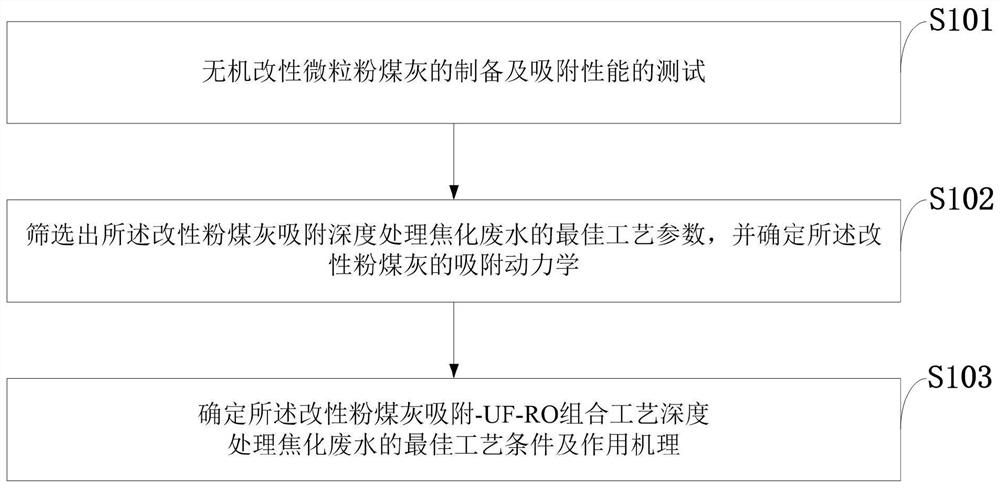

[0055] (1) Inorganic modification of fly ash and testing its adsorption performance.

[0056] Sodium hydroxide is used as a modifier to modify fly ash by hydrothermal method, and the modified fly ash is used to evaluate the adsorption performance of coking wastewater to test the ability and effect of modified fly ash to adsorb different types of pollutants .

[0057] (2) Based on the adsorption capacity of modified fly ash coking wastewater, determine the process conditions to achieve the maximum adsorption effect. The adsorption kinetics of coking wastewater by modified fly ash was studied.

[0058] Using a small experimental device in the laboratory, the secondary effluent of coking wastewater is used for adsorption of modified fly ash. By measuring the COD, ammonia nitrogen and turbidity of the influent and effluent, the pH value, dosage, and adsorption time of modified fly ash are studied. The influence of the conditions on the water quality of the m...

Embodiment 2

[0076] 1. Method

[0077] ① Preparation of inorganic modified particulate fly ash and test of its adsorption performance

[0078] Sodium hydroxide was used as modifier to modify fly ash by hydrothermal method. First, clean the original fly ash, wash it with deionized water for 3 to 4 times, then stir it with an electric mixer at a speed of 100r / min for 30min, and then settle it to remove the upper turbid liquid. The cleaned fly ash was dried in an oven at 105°C for 24 hours, during which it was stirred several times to prevent dry agglomeration. Grind on a ball mill, pass through a 120-mesh sieve, and dry for later use. Take 4 parts of a certain amount of pretreated fly ash, add 2mol / L, 4mol / L, 6mol / L, 8mol / L NaOH solution (solid-liquid ratio is 1g / 20mL) respectively to the fly ash, magnetically stir After 30 minutes, the solution was added to a polyethylene tetrafluoro reactor, and reacted in an electric constant temperature blast drying oven at 90°C for 2.5h, washed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com