Composite coating modified high-nickel NCA positive electrode material and preparation method thereof

A positive electrode material and coating technology, applied in the field of composite coating modified high-nickel NCA positive electrode material and its preparation, can solve the problems of low capacity and poor cycle performance of positive electrode materials, and achieve the solution of cycle performance degradation, increase capacity, The effect of improving capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

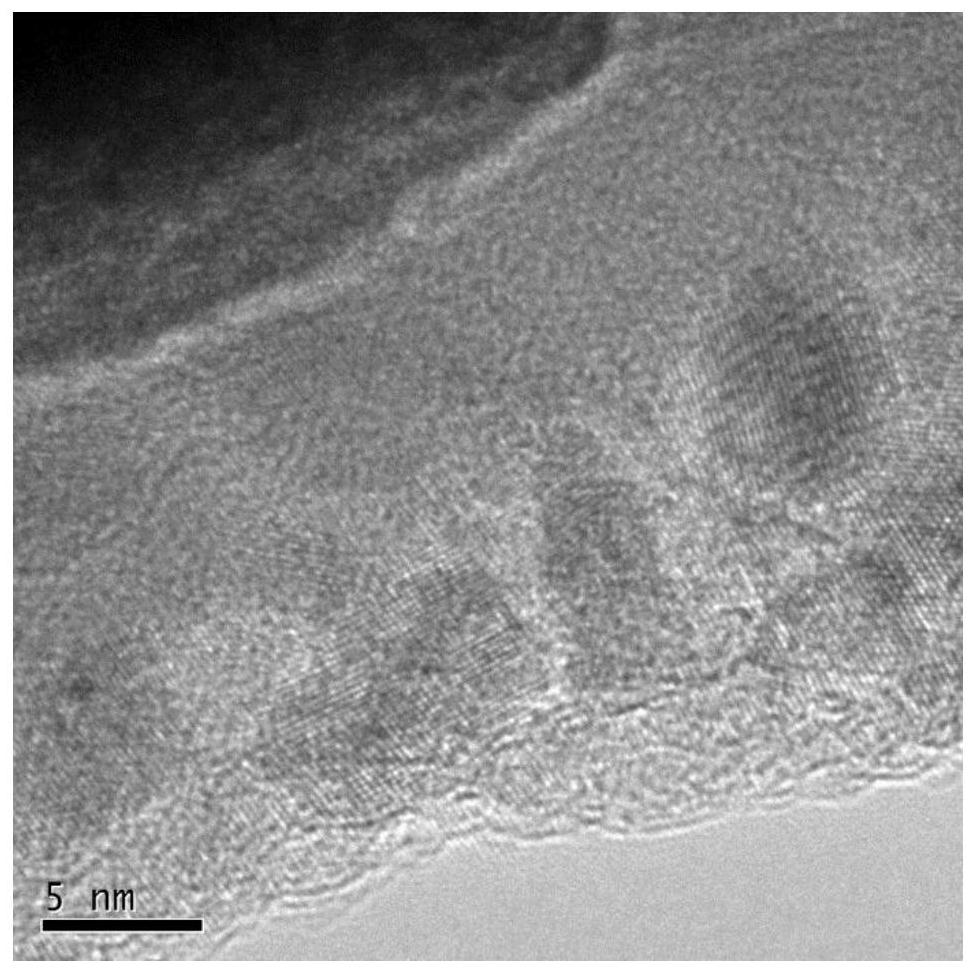

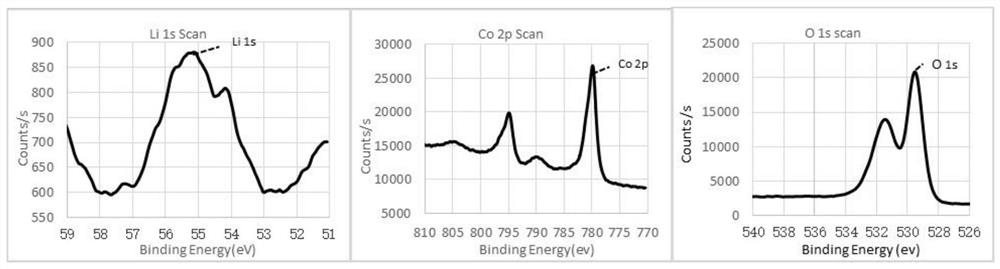

[0034] A composite coating modified high-nickel NCA positive electrode material. The NCA positive electrode material uses nickel-cobalt lithium aluminate as a matrix, and a composite coating modification layer is wrapped on the surface of the substrate. The composite coating modification layer is made of LiCoO 2 with Co 2 o 3 Composition, the content of the composite coating modified layer is 1.0wt% of the total weight of the matrix. LiCoO in composite coating modified layer 2 with Co 2 o 3 The molar ratio is 1:1.5.

[0035] The chemical formula of lithium nickel cobalt aluminate is Li 1.01 Ni 0.913 co 0.069 al 0.015 Ti 0.003 o 2 .

[0036] The method for preparing the above-mentioned NCA cathode material comprises the following steps:

[0037] S1. Preparation of precursors:

[0038] According to the condition of the molar ratio of Ni:Co 93:7, nickel sulfate solution and cobalt sulfate solution are mixed as raw materials, the metal molar concentration of the nicke...

Embodiment 2

[0047] A composite coating modified high-nickel NCA positive electrode material. The NCA positive electrode material uses nickel cobalt lithium manganese oxide as a matrix, and a composite coating modification layer is wrapped on the surface of the substrate. The composite coating modification layer is made of LiCoO 2 with Co 2 o 3 Composition, the content of the composite coating modification layer is 1.0wt% of the total weight of the matrix. LiCoO in composite coating modified layer 2 with Co 2 o 3 The molar ratio is 1:2.

[0048] The chemical formula of lithium nickel cobalt manganese oxide is Li 1.01 Ni 0.913 co 0.069 al 0.015 Ti 0.003 o 2 .

[0049] The method for preparing the above-mentioned NCA cathode material comprises the following steps:

[0050] S1. Preparation of precursors:

[0051] Under the condition of the molar ratio of Ni:Co 93:7, nickel nitrate solution and cobalt sulfate solution are mixed as raw materials, the metal molar concentration of th...

Embodiment 3

[0058] A composite coating modified high-nickel NCA positive electrode material. The NCA positive electrode material uses nickel-cobalt lithium aluminate as a matrix, and a composite coating modification layer is wrapped on the surface of the substrate. The composite coating modification layer is made of LiCoO 2 with Co 2 o 3 Composition, the content of the composite coating modified layer is 0.6wt% of the total weight of the matrix. LiCoO in composite coating modified layer 2 with Co 2 o 3 The molar ratio is 1:1.

[0059] The chemical formula of lithium nickel cobalt aluminate is Li 1.05 Ni 0.923 co 0.049 al 0.026 Y 0.002 o 2 .

[0060] The method for preparing the above-mentioned NCA cathode material comprises the following steps:

[0061] S1. Preparation of precursors:

[0062] Under the condition of the molar ratio of Ni:Co 95:5, the nickel nitrate solution and the cobalt chloride solution are mixed as raw materials, the metal molar concentration of the nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com