Substrate type SOFC anode support body and preparation method and equipment thereof

A technology for anode support and manufacturing equipment, which is applied in the direction of battery electrodes, final product manufacturing, sustainable manufacturing/processing, etc. It can solve the problems of SOFC easy fracture failure, deterioration of high-temperature mechanical properties, and increased pressurization pressure, etc., to achieve increased Three-phase reaction interface, improved electrical conductivity, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a substrate-type SOFC anode support, comprising the steps of:

[0029] 1) Preparation of pouring slurry

[0030] In terms of parts by mass, 600-1000 parts of NiO-YSZ powder, 20-100 parts of pore-forming agent, 10-30 parts of polyacrylic acid, 150-250 parts of acrylamide monomer, 1-2.5 parts of cross-linking agent and 100 parts ~150 parts of deionized water, mix well, adjust the pH value to 9~10 with alkaline solution, then add 5~30 parts of plasticizer, mix well to obtain the mixed slurry;

[0031] The NiO content in the NiO-YSZ powder can be 40% to 70%, and the YSZ content can be 60% to 30%.

[0032] After the mixed slurry is ground, it passes through a 100-200 mesh screen, and can be mixed with a ball mill, and the discharge port of the ball mill is blocked with a 100-200 mesh screen or screen cloth, and it is first filtered through a screen during the discharge process. Degassing, and at the same time filter out the coa...

Embodiment 1

[0057] 1) In terms of parts by mass, 600 parts of NiO-YSZ powder, 50 parts of polymethyl methacrylate, 10 parts of polyacrylic acid, 150 parts of acrylamide monomer, 2 parts of methylenebisacrylamide and 150 parts of Ionized water, mixed evenly, adjusted the pH value to between 9 and 10 with ammonia water, then added 10 parts of glycerin, mixed evenly, to obtain a mixed slurry;

[0058] Transfer the mixed slurry to a ball mill, feed in batches at a ball-to-material ratio of 2:1, mix and mill for 10 hours, set a 200-mesh screen at the outlet of the ball mill, and transfer the sieved slurry to a vacuum In the stirring and degassing device, stir for 1 hour under the vacuum degree of -0.06Pa, then add 5 parts of 50% tetramethylethylenediamine aqueous solution and 2 parts of 6% ammonium persulfate aqueous solution, and mix well to obtain the pouring slurry;

[0059] 2) Pouring and molding

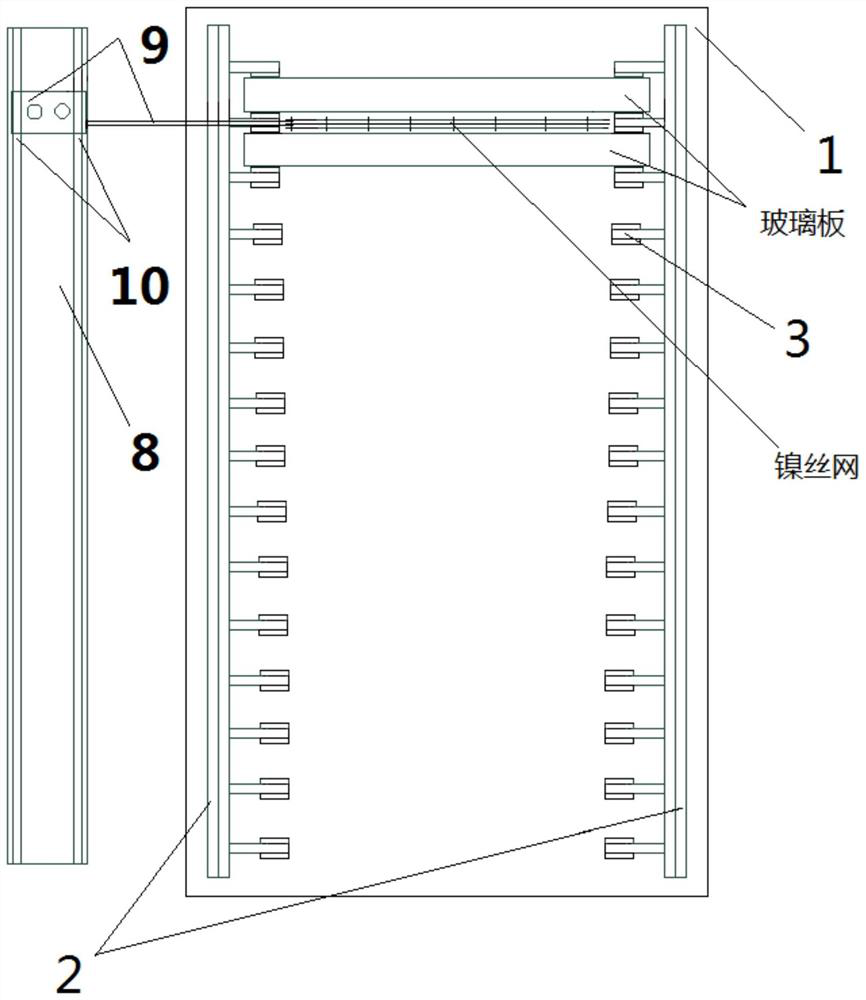

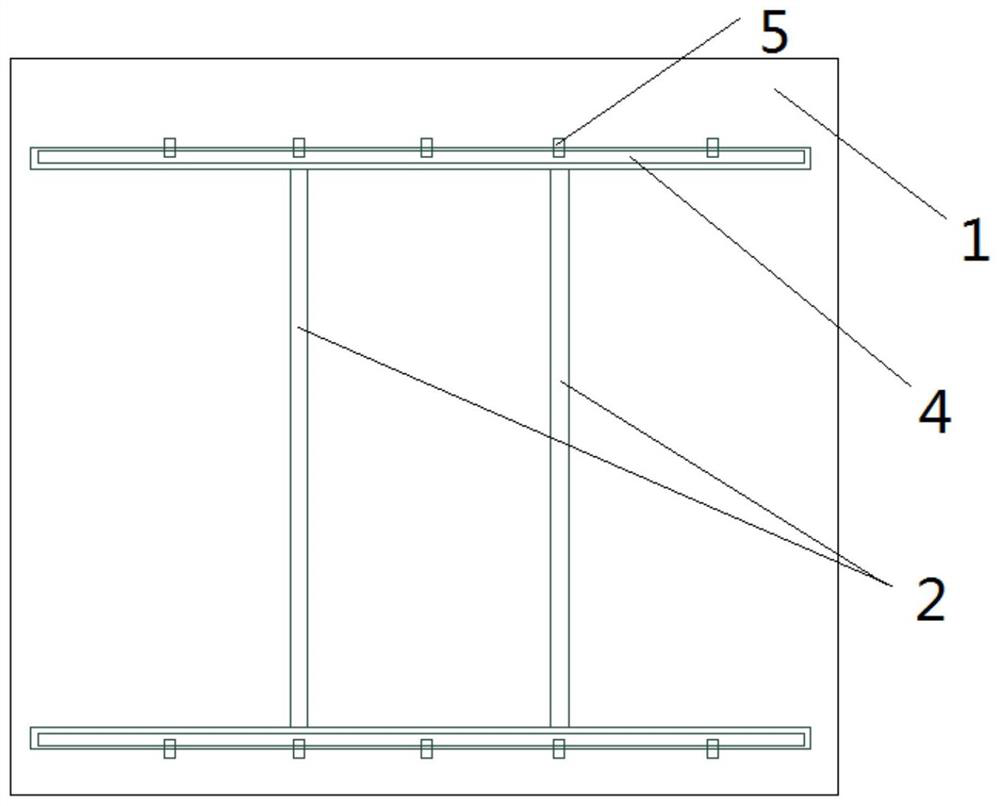

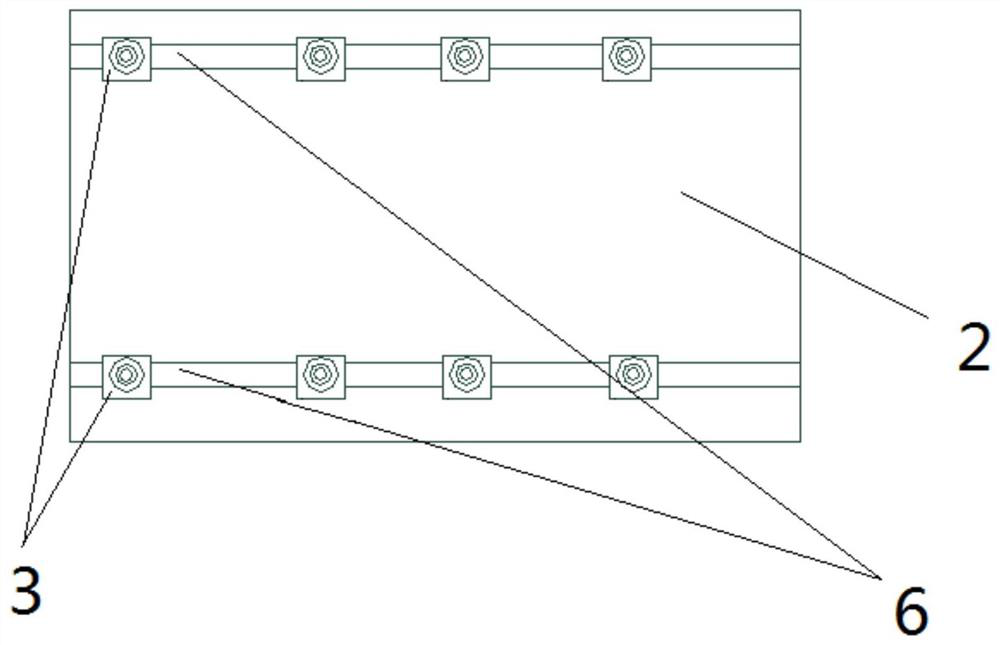

[0060] Lay nickel wire between two parallel glass plates to form a grid, then pour the pour...

Embodiment 2

[0063] 1) In terms of parts by mass, mix 700 parts of NiO-YSZ powder, 20 parts of starch, 20 parts of polyacrylic acid, 250 parts of acrylamide monomer, 1 part of methylenebisacrylamide and 150 parts of deionized water , using tetramethylammonium hydroxide to adjust the pH value to between 9 and 10, then add 5 parts of glycerin, and mix to obtain a mixed slurry;

[0064] Transfer the mixed slurry to a ball mill, feed in batches at a ball-to-material ratio of 2:1, mix and mill for 18 hours, set a 200-mesh screen at the outlet of the ball mill, and transfer the sieved slurry to a vacuum In the stirring and degassing device, stir for 2 hours under a vacuum of -0.06Pa, then add 2 parts of 50% tetramethylethylenediamine aqueous solution and 10 parts of 6% ammonium persulfate aqueous solution, and mix well to obtain a pouring slurry;

[0065] 2) Pouring and molding

[0066] Lay nickel wire between two parallel glass plates to form a grid, then pour the pouring slurry between the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com