Dye laser structure based on guided mode resonance effect

A dye laser and guided mode resonance technology, which is applied to the structure/shape of lasers, optical resonators, and laser components, can solve the problems of increasing the complexity of the optical path and unfavorable detectors for signal collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

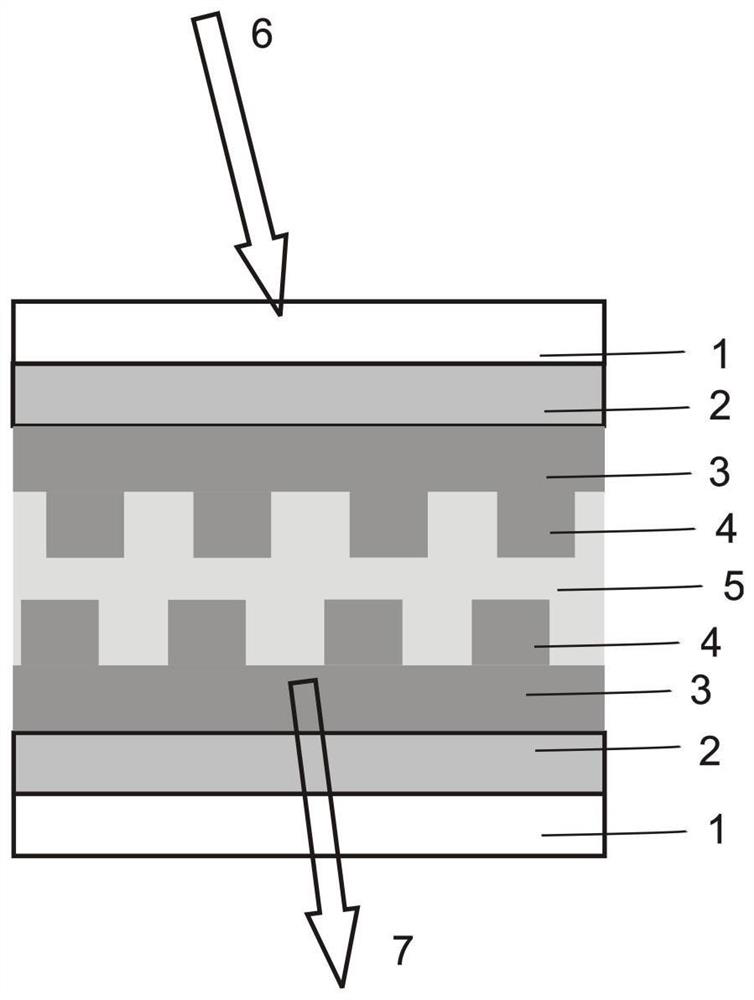

[0022] Embodiment 1: select two transparent quartz glass substrates 1 of identical size, prepare low-refractive-index film 2 on substrate, as porous silicon etc., the thickness of low-refractive-index film 2 is greater than 1 micron; After this, in low-refractive-index film On top of 2, uniform waveguide layer 3 and grating 4 are prepared. The uniform waveguide layer 3 and grating 4 are composed of the same material, both of which are oxides with high refractive index, such as titanium oxide, tantalum oxide, etc. The structural parameters prepared on the two substrates It is exactly the same; finally, the organic laser dye IR140 is dissolved in a polyurethane solvent, and is prepared in the middle of the two gratings by spin coating, etc., to form the structure involved in the present invention, such as figure 1 shown.

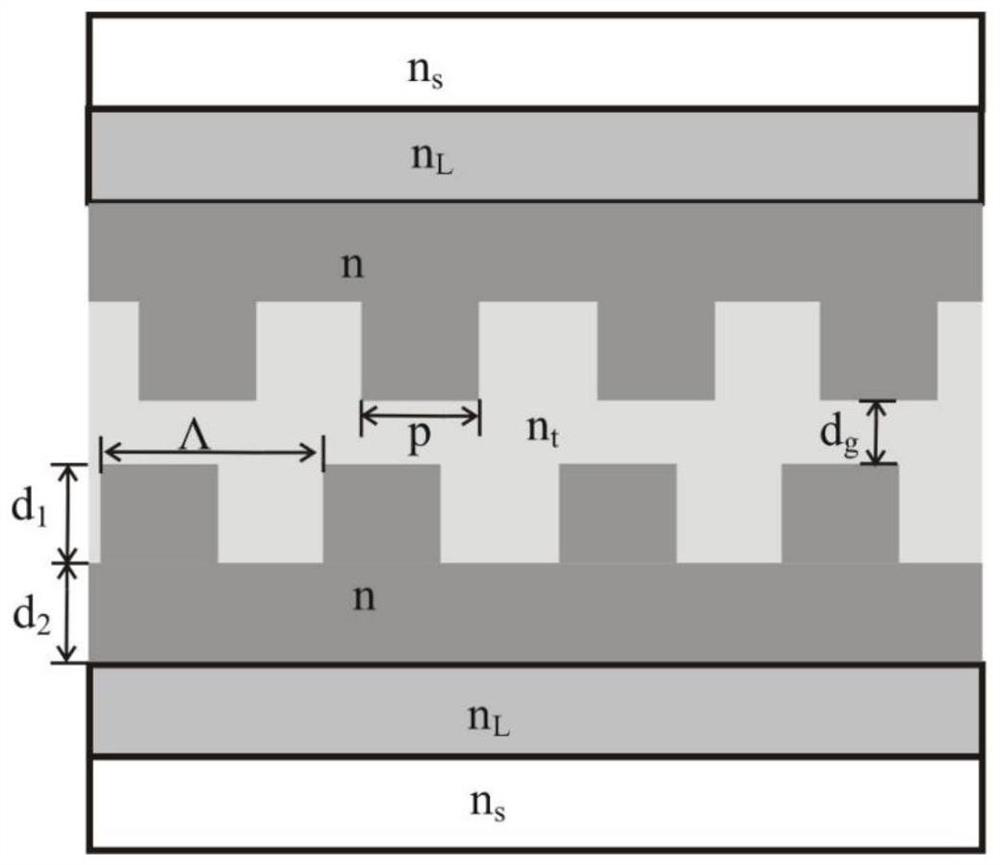

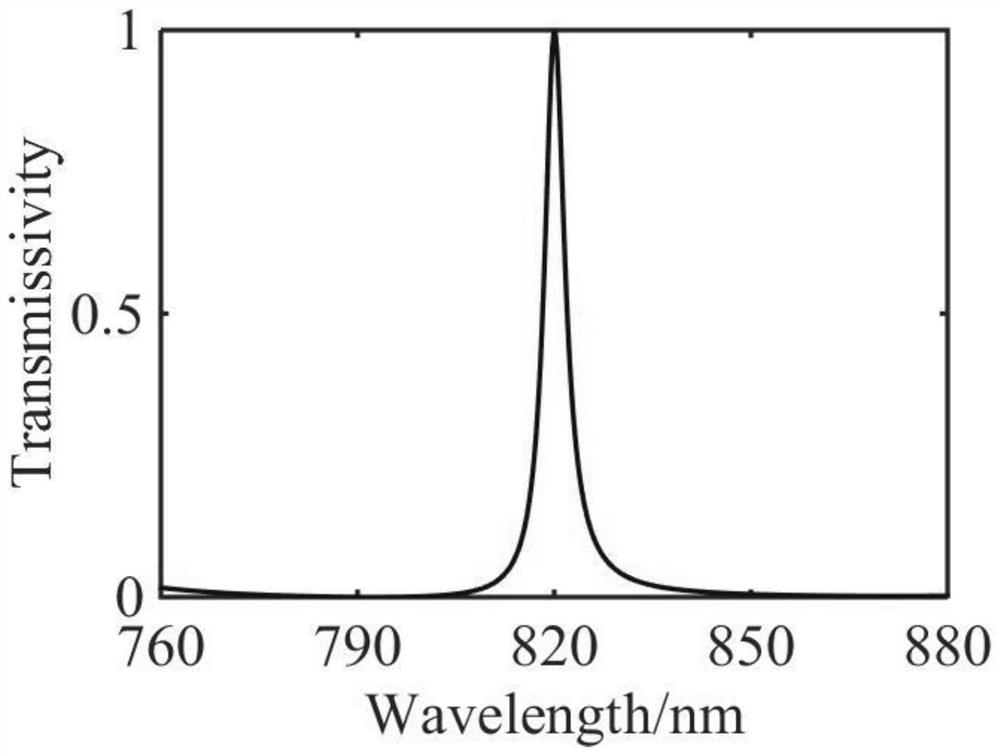

[0023] Structure parameters such as figure 2 As shown, the resonant peak of the transmission guided mode will be located at 820nm: the refractive index of t...

Embodiment 2

[0024] Example 2: The only difference from Example 1 is that the parameters of the structure are different. The transmission resonance peak is located at 870nm: the refractive index of the grating material and the waveguide layer material are both n=2.4, the period Λ=614nm, and the depth of the grating groove is d 1 =260nm and grating width p=184.2nm, waveguide layer thickness is d 2 =60nm. The gap thickness of the two grating structures is d g =320nm, the refractive index of the low refractive index film is n s =1.1, the refractive index of the middle layer is n t =1.3, the refractive index of the glass substrate is n s =1.46. When the laser dye IR140 is not added, the broad spectrum is incident on the structure composed of the above parameters, resulting in a guided mode resonance transmission peak at 870nm, such as Figure 5 As shown, this peak matches the emission wavelength of the near-infrared laser dye IR140. If the organic laser dye IR140 is dissolved in a polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com