Green method for preparing high-quality graphene powder on large scale at ultra-low cost

A graphene powder, high-quality technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as high cost, toxicity, flammability and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of Hydrophilic Polymer Solutions. The hydrophilic polymer is dissolved in water to obtain an aqueous solution containing the hydrophilic polymer. Wherein water can be ultrapure water. Among them, the hydrophilic polymers include sodium dodecylbenzene sulfonate, sodium lauryl sulfate, polyvinylpyrrolidone, sodium oleate, sodium lauryl sulfate, sodium dioctyl succinate, sodium glycocholate, One or a mixture of benzalkonium chloride, polyethylene glycol, polyoxyethylene ether series, and alkanolamide series. The content of the hydrophilic polymer in the aqueous solution containing the hydrophilic polymer can be 0.5-20 wt%.

[0032] adding the alkaline reagent into the aqueous solution containing the hydrophilic polymer and mixing uniformly to obtain an aqueous solution containing the hydrophilic polymer and the alkaline reagent. Wherein, the specified alkaline reagents include sodium carbonate, sodium bicarbonate, potassium carbonate, potassium bicarbonate, ...

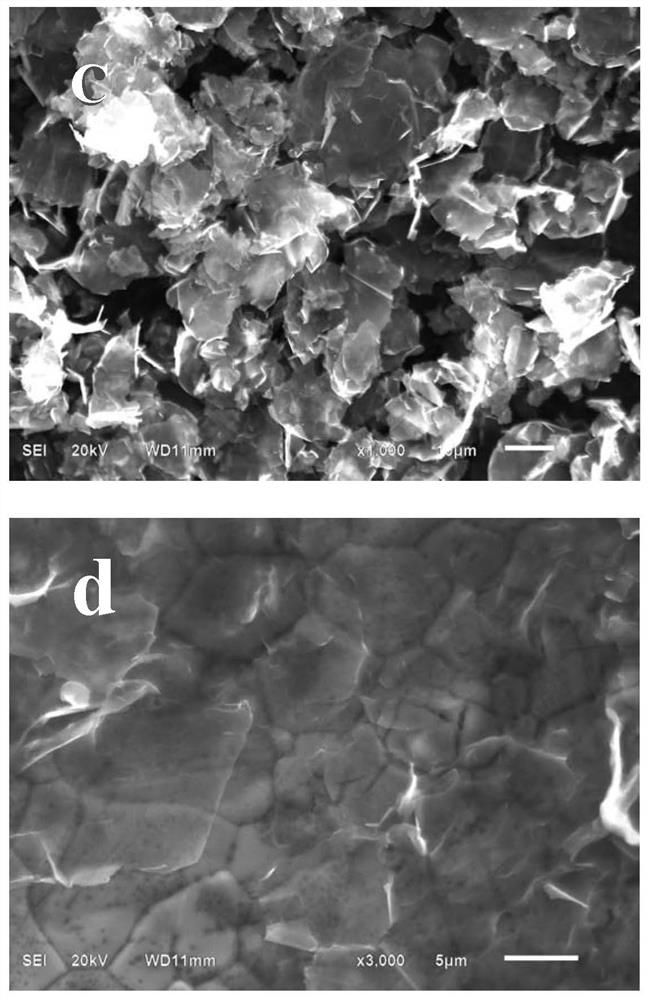

Embodiment 1

[0043] Dissolve 1 gram of sodium dodecylbenzenesulfonate in 100 grams of ultrapure water, then add 1 gram of ammonium bicarbonate, stir to dissolve it completely, and obtain an aqueous solution containing hydrophilic polymers and alkaline reagents. Then add 10 grams of expanded graphite, and grind at a high speed for 0.5 hour (8 m / s at a linear velocity) in a grinder, and take out the ground graphite slurry. The graphite slurry is diluted to 500 milliliters with ultrapure water, and placed in a powerful ultrasonic machine for ultrasonic treatment for 0.5 hours (ultrasonic treatment power 2.4kW), to obtain a graphene aqueous solution in which graphene is uniformly dispersed;

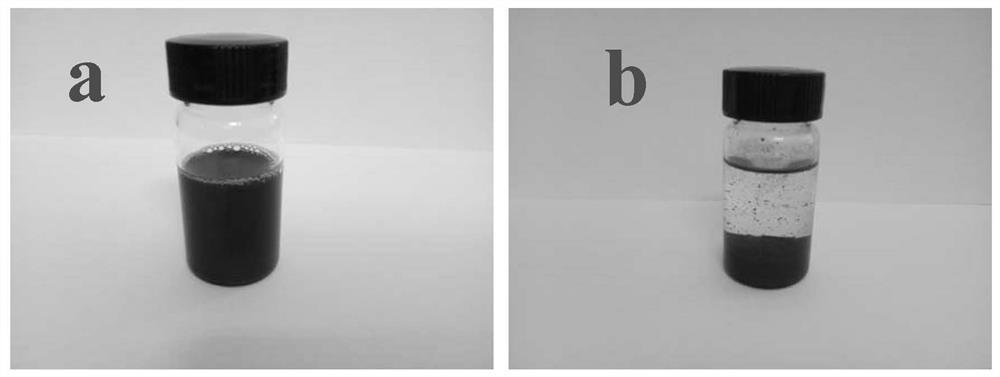

[0044] The prepared graphene aqueous solution was left to stand for 12 hours, and the graphene stable dispersion solution (or graphene dispersion solution) of the upper layer was taken, and 0.5 gram of magnesium chloride was added and stirred evenly to obtain a graphene precipitation solution;

[0045] Th...

Embodiment 2

[0049] Dissolve 1 gram of sodium lauryl sulfate in 100 grams of ultrapure water, then add 1 gram of ammonia water (concentration: 1 wt%), stir to make it completely dissolved, and obtain an aqueous solution containing hydrophilic polymers and alkaline reagents. Then add 10 grams of expanded graphite, grind at a high speed for 0.5 hour (line speed 10 m / s) in the grinder, and take out the graphite slurry that has been ground. The graphite slurry is diluted to 500 milliliters with ultrapure water, and placed in a powerful ultrasonic machine for ultrasonic treatment for 0.5 hours (ultrasonic treatment power 3kW), to obtain a graphene aqueous solution in which graphene is uniformly dispersed;

[0050] The prepared graphene aqueous solution was left to stand for 12 hours, and the graphene stable dispersion solution (or graphene dispersion solution) of the upper layer was taken, and 0.5 gram of barium chloride was added and stirred to obtain the graphene precipitation solution;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com