Geothermal exploitation low-thermal-resistance low-density composite well cementing material and preparation method thereof

A low thermal resistance, low density technology, applied in chemical instruments and methods, drilling composition, sustainable manufacturing/processing, etc., can solve problems such as large thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

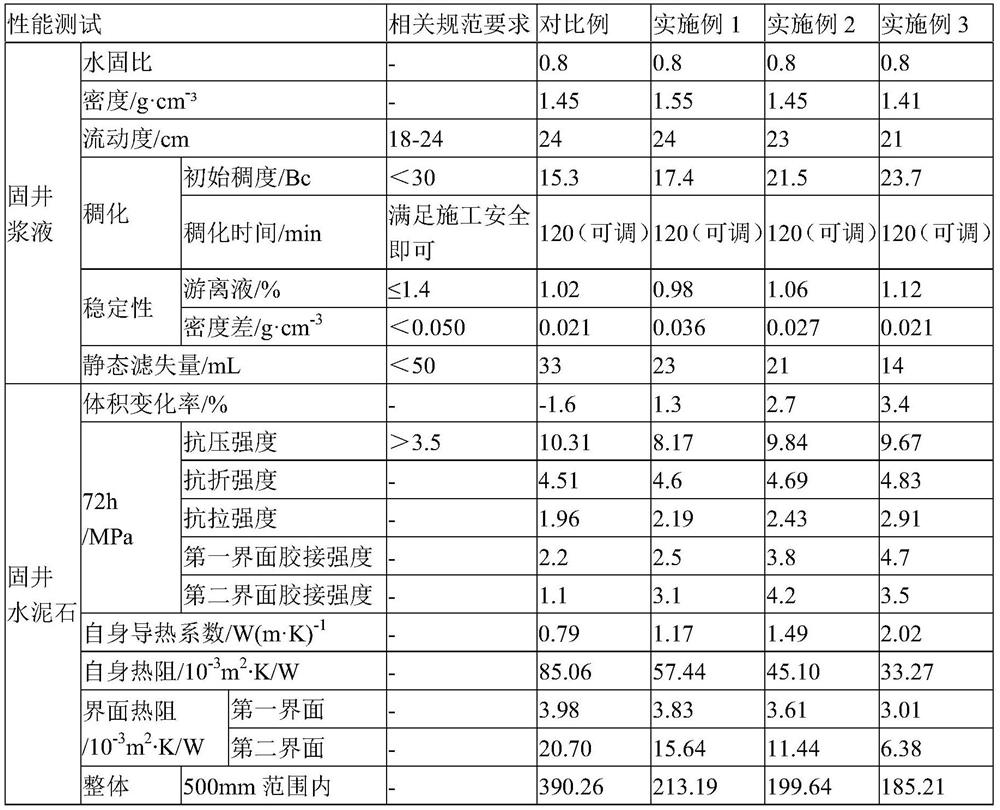

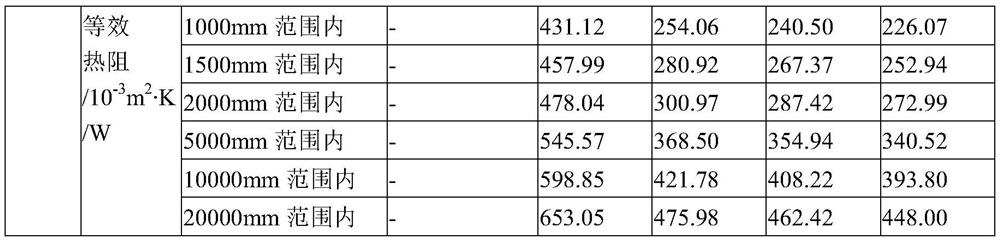

Examples

Embodiment 1

[0055] This embodiment provides a low thermal resistance and low density composite cementing material for geothermal exploitation, which is made of the following raw materials in parts by weight: 100 parts of solid phase material, 80 parts of water, 0.4 part of latex, and defoamer 0.1 copies;

[0056] The solid-phase material, in parts by weight, is made of the following raw materials: 2 parts of mixed flake graphite, 0.2 part of graphite oxide, 0.2 part of hexagonal boron nitride, 0.2 part of polyacrylonitrile-based carbon fiber, pitch 0.5 parts of base carbon fiber, 15 parts of quartz powder, 3 parts of calcium carbonate whiskers, 9 parts of silica fume, 7 parts of fly ash, 6 parts of blast furnace slag, 0.2 parts of dispersant, and 0.2 parts of fluid loss reducer 2 parts, 0.2 parts of early strength agent, 0.5 parts of lattice expansion agent, 2 parts of crystal form stabilizer, the balance is oil well cement, and the sum of the parts by weight of raw materials is 100 parts...

Embodiment 2

[0063] This embodiment provides a low thermal resistance and low density composite cementing material for geothermal exploitation, which is made of the following raw materials in parts by weight: 100 parts of solid phase material, 80 parts of water, 0.4 part of latex, and defoamer 0.1 copies;

[0064] The solid phase material, in parts by weight, is made of the following raw materials: 6 parts of mixed flake graphite, 0.5 part of graphite oxide, 0.4 part of hexagonal boron nitride, 0.5 part of polyacrylonitrile-based carbon fiber, pitch 0.5 parts of base carbon fiber, 12 parts of quartz powder, 4 parts of calcium carbonate whiskers, 7.5 parts of silica fume, 7 parts of fly ash, 5 parts of blast furnace slag, 0.2 parts of dispersant, and 0.2 parts of fluid loss reducer 2 parts, 0.2 parts of early strength agent, 0.5 parts of lattice expansion agent, 2 parts of crystal form stabilizer, the balance is oil well cement, and the sum of the parts by weight of raw materials is 100 par...

Embodiment 3

[0068] This embodiment provides a low thermal resistance and low density composite cementing material for geothermal exploitation, which is made of the following raw materials in parts by weight: 100 parts of solid phase material, 80 parts of water, 0.4 part of latex, and defoamer 0.1 copies;

[0069] The solid-phase material, in parts by weight, is made of the following raw materials: 10 parts of mixed graphite flakes, 0.8 parts of graphite oxide, 0.6 parts of hexagonal boron nitride, 0.8 parts of polyacrylonitrile-based carbon fiber, pitch 0.5 parts of base carbon fiber, 9 parts of quartz powder, 5 parts of calcium carbonate whiskers, 6 parts of silica fume, 7 parts of fly ash, 4 parts of blast furnace slag, 0.2 parts of dispersant, and 0.2 parts of fluid loss reducer 2 parts, 0.2 parts of early strength agent, 0.5 parts of lattice expansion agent, 2 parts of crystal form stabilizer, the balance is oil well cement, and the sum of the parts by weight of raw materials is 100 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com