Platinum monatomic hydrogen oxidation reaction electrocatalyst based on reactant enrichment and preparation method thereof

An electrocatalyst, oxidation reaction technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve problems such as reducing the utilization rate of Pt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 A preparation method of electrocatalyst for platinum single-atom hydrogen oxidation reaction based on reactant enrichment

[0045] The preparation method of embodiment 1 comprises the following steps carried out in sequence:

[0046] Preparation of spherical nano-silica carrier by chemical precipitation method:

[0047] Take 20L ethanol and 40L deionized water, mix well, add 0.6L tetramethyl silicate and 0.2kg cetyltrimethylammonium chloride (CTAC) surfactant, stir at room temperature for 1 hour, then add 0.8 L of ammonia solution with a mass fraction of 25%, was stirred at room temperature for 4 hours, and the filtered product was washed with deionized water and ethanol successively, dried at 60°C, and then heated at 600°C in air for 6 hours to obtain spherical nanometer Silica carrier, spare.

[0048] Among them, the spherical nano-silica carrier can also be obtained through commercial channels.

[0049] S1: Preparation of Pt x+ / SiO 2 Intermediates:

...

Embodiment 2-8

[0061] Example 2-8 Preparation method of platinum single-atom hydrogen oxidation reaction electrocatalyst based on reactant enrichment

[0062] Examples 2-8 are respectively a preparation method of electrocatalysts for platinum single-atom hydrogen oxidation based on the enrichment of reactants. These preparation methods are basically the same as in Example 1, the difference lies in the selection of raw materials and the adjustment of other process parameters. See Table 1 for raw material marking codes, and Table 2 for process parameter adjustments.

[0063] Table 1 Raw material marking code

[0064]

[0065] Table 2 embodiment 2-8 technological parameter

[0066]

[0067]

[0068]

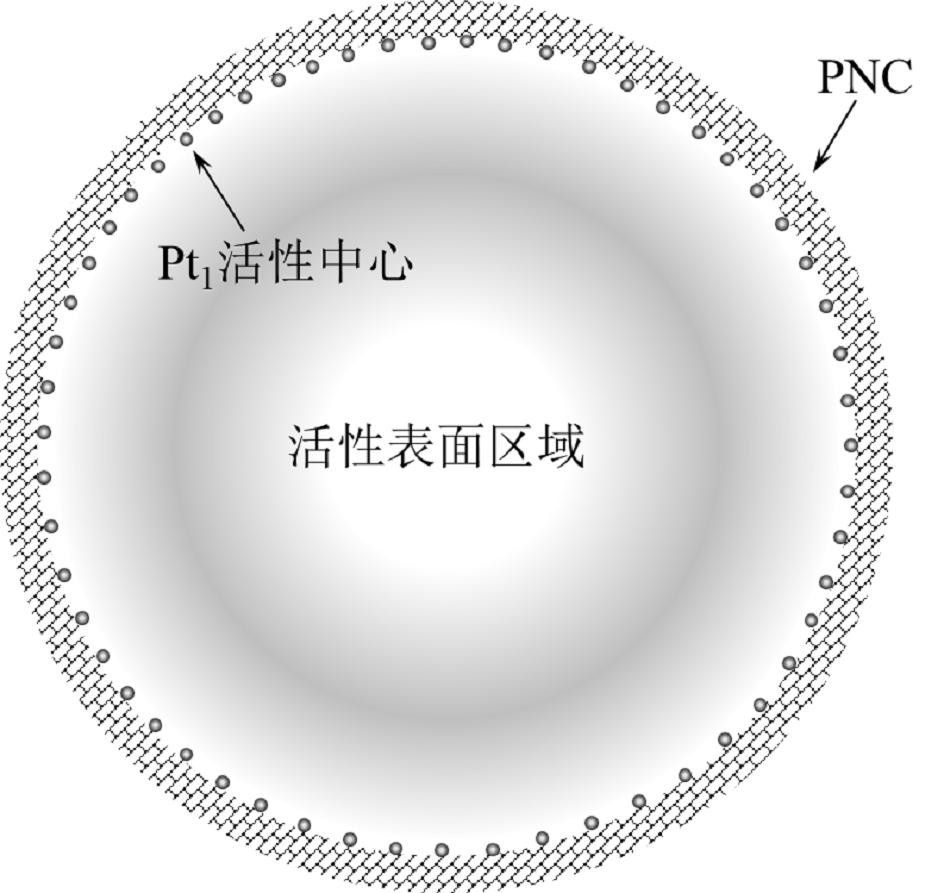

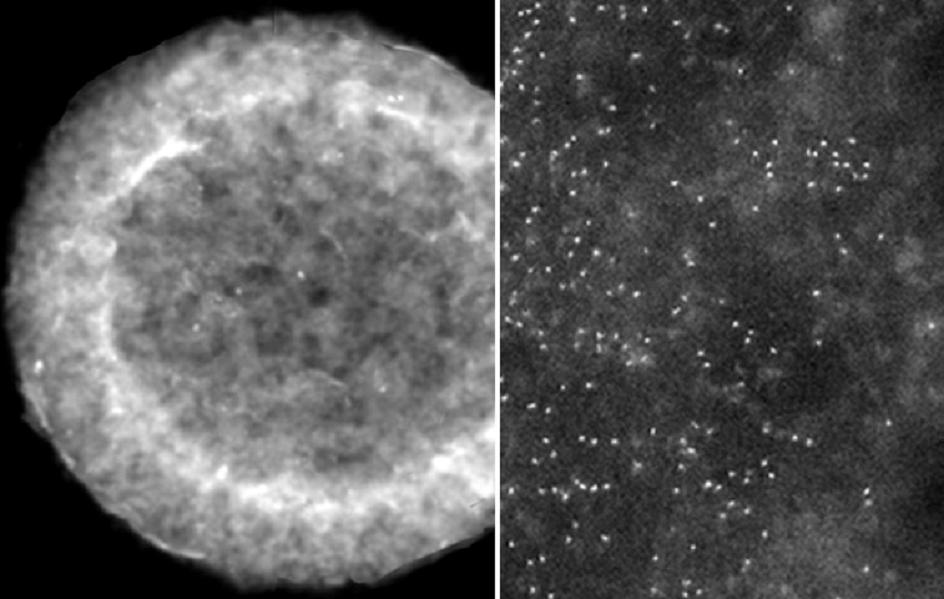

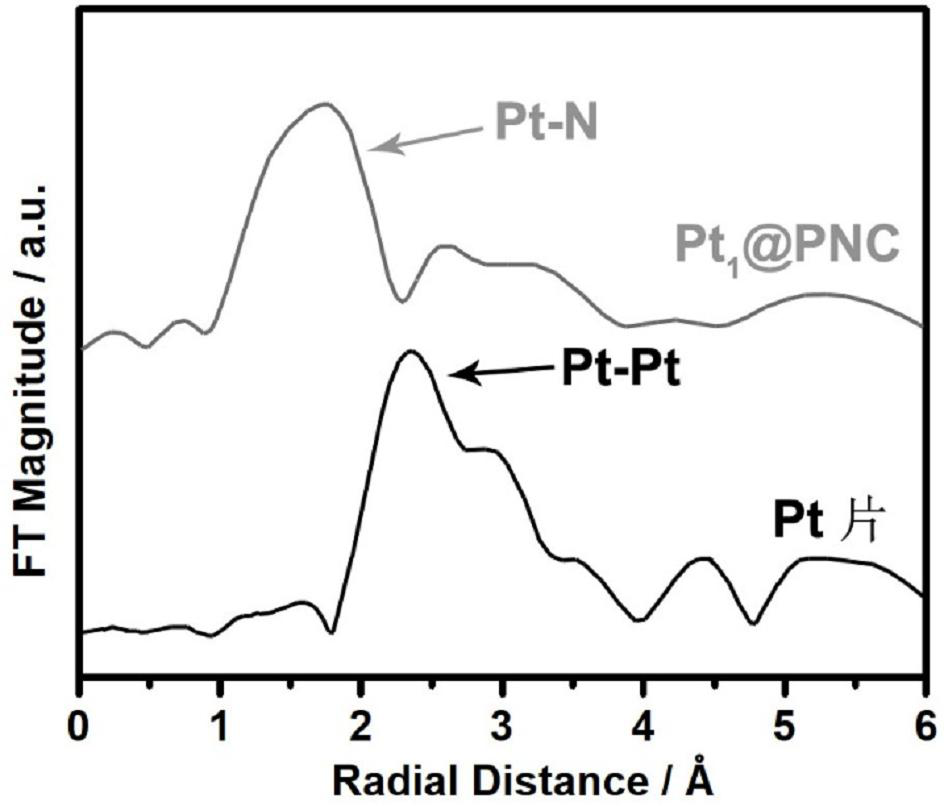

[0069] The prepared platinum single-atom hydrogen oxidation reaction electrocatalyst based on reactant enrichment is Pt 1 @PNC Catalyst, J2-J8 are all hollow core-shell electrocatalysts composed of catalytic active centers and porous nitrogen-doped hollow carbon shells (PNC), in whic...

Embodiment 9

[0070] Example 9 Performance detection of platinum single-atom hydrogen oxidation reaction electrocatalyst based on reactant enrichment

[0071] 1) Pt 1 H of @PNC catalyst J1 and Pt / C 2 -Stripping curve

[0072] Experimental method: 5 mg of Pt 1 Mix @PNC with 970 μL of isopropanol and 30 μL of Nafion membrane solution (5% by mass, DuPont), and disperse evenly by ultrasonic oscillation for 40 minutes, draw 5 μL and evenly coat it on the glassy carbon rotating ring disk electrode, and dry it in the air for 10 minutes to obtain the catalyst Working electrode JJ1;

[0073] Place the catalyst working electrode in hydrogen-saturated 0.1M HClO 4 After 20 minutes in the electrolyte, switch the hydrogen gas to nitrogen to dissolve the hydrogen gas dissolved in the electrolyte, and record the linear scanning polarization curve on the electrochemical workstation (CHI650E, Shanghai Chenhua Instrument Co., Ltd.), and the scanning range is 0.075-1.0V (relative to the standard Hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com