Preparation method of composite material with enamel-like structure

A composite material and enamel technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems that composite materials do not have actual production potential, "vertical" structure is difficult to imitate and manufacture, and experimental operations are complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention discloses a preparation method of a enamel-like structure composite material, and the adopted technical scheme is as follows:

[0040] A method for preparing a enamel-like structure composite material, specifically comprising the following steps:

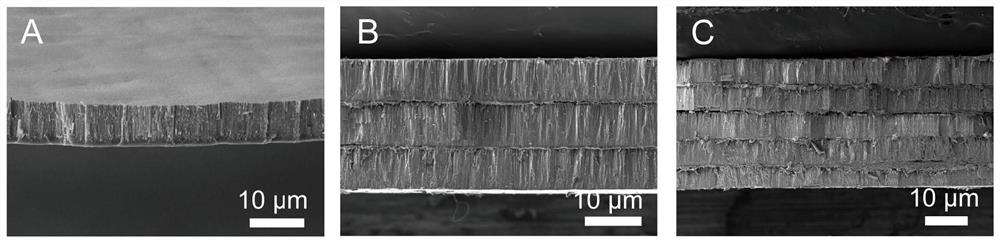

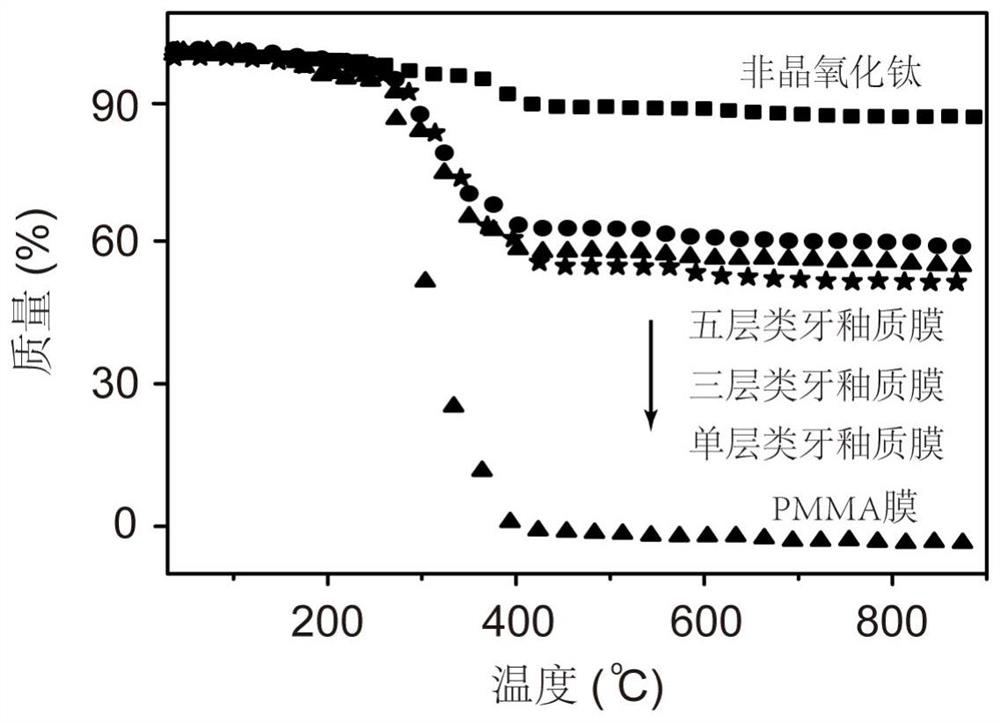

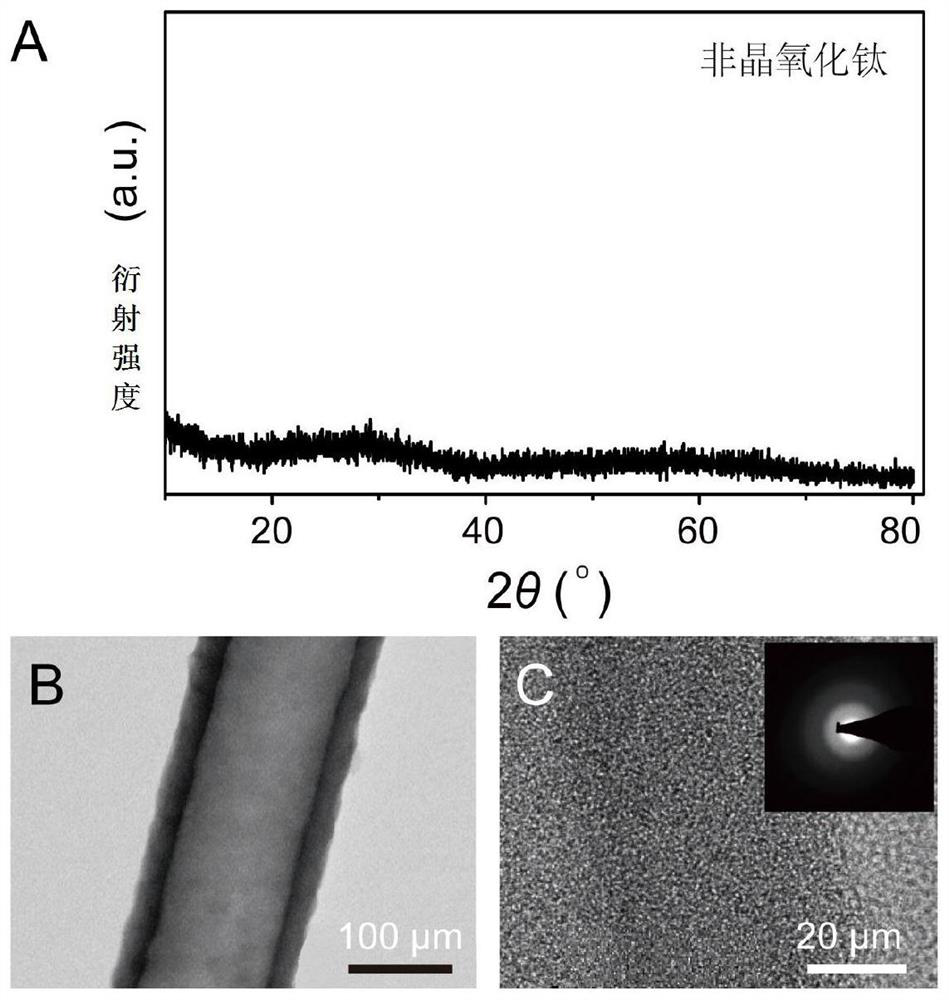

[0041] S1, weigh 500mL of anhydrous ethylene glycol, add 0.1wt% of ammonium fluoride and 1wt% of hydrogen peroxide to prepare an electrolyte, soak a titanium sheet with a purity of 0.9-0.99 in the electrolyte, and set a voltage of 60V to anodize for 1h , to obtain an array of amorphous titanium oxide nanotubes, the outer diameter of the obtained amorphous titanium oxide nanotube array is 120 nm, and the length is 5 μm;

[0042] S2, preparing a 0.1wt% PMMA solution, soaking the amorphous titanium oxide nanotube array obtained in step S1 in the PMMA solution for 12 hours, taking it out and drying it naturally;

[0043] S3, take the PMMA solution and add it dropwise on the dry amorphous tit...

Embodiment 2

[0046] Embodiment 2 of the present invention discloses a preparation method of a enamel-like structure composite material, and the adopted technical scheme is as follows:

[0047] A method for preparing a enamel-like structure composite material, specifically comprising the following steps:

[0048]S1, weigh 500mL of anhydrous ethylene glycol, add 0.6wt% ammonium fluoride and 5wt% hydrogen peroxide to prepare an electrolyte, soak a titanium sheet with a purity of 0.9-0.99 in the electrolyte, and anodize at 60V for 5h , to obtain an array of amorphous titanium oxide nanotubes, the outer diameter of the obtained amorphous titanium oxide nanotube array is 120 nm, and the length is 15 μm;

[0049] S2, preparing a 0.5wt% PMMA solution, soaking the amorphous titanium oxide nanotube array obtained in step S1 in the PMMA solution for 18 hours, taking it out and drying it naturally;

[0050] S3, take the PMMA solution and add it dropwise on the dry amorphous titanium oxide nanotube ar...

Embodiment 3

[0053] Embodiment 3 of the present invention discloses a preparation method of a enamel-like structure composite material, and the adopted technical scheme is as follows:

[0054] A method for preparing a enamel-like structure composite material, specifically comprising the following steps:

[0055] S1, weigh 500mL of anhydrous ethylene glycol, add 1wt% of ammonium fluoride and 10wt% of hydrogen peroxide to prepare an electrolyte, soak a titanium sheet with a purity of 0.9-0.99 in the electrolyte, and set a voltage of 60V to anodize for 10h. Obtaining an array of amorphous titanium oxide nanotubes, the outer diameter of the obtained amorphous titanium oxide nanotube array is 120 nm, and the length is 25 μm;

[0056] S2, preparing a 1wt% PMMA solution, soaking the amorphous titanium oxide nanotube array obtained in step S1 in the PMMA solution for 18 hours, taking it out and drying it naturally;

[0057] S3, take the PMMA solution and add it dropwise on the dry amorphous titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com