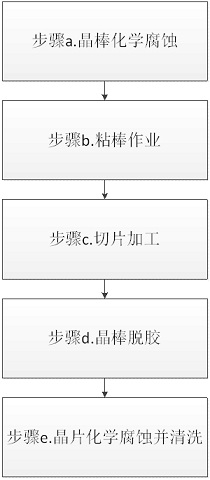

Slicing method of large-size ultrathin lithium niobate wafer

A lithium niobate, large-size technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problem of lack of large-size ultra-thin lithium niobate wafer slicing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a) Place the lithium niobate crystal stick in a sealed container with nitric acid and hydrofluoric acid uniform mixed solution, the corrosion temperature is 20 ° C, the corrosion time is 24 hours, and the stress is fully released. ;

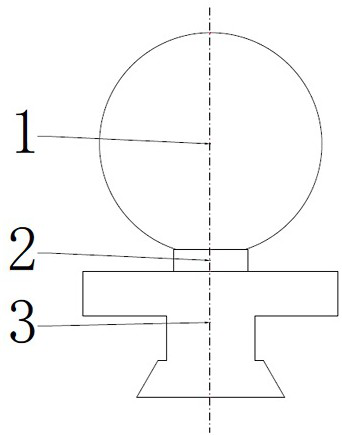

[0042] b) Use pure water and alcohol to clean the lithium niobate carbon whose stress is sequentially cleaned, and then secure the wafers 1 and the glass strip 2 to the adhesive, put it into the clamp, and use the crystal instrument to grasp the crystal Deviation, and trimmed the waffle crystal direction by the machine tool, and then fixed the thickness of the wafers 1 after the repairing crystal, the binder is fixed to the reference block 3, and the upper and both sides are not viscous with the adhesive. Paste ate, see figure 2 with image 3 , Obtain lithium tods of lithium niobate to be sliced;

[0043] c) Focus on the cutting fluid according to the mass fraction of each of the following components, that is, 10% cycloalkyl oil, 30% of paraffi...

Embodiment 2

[0047] a) in Example 1;

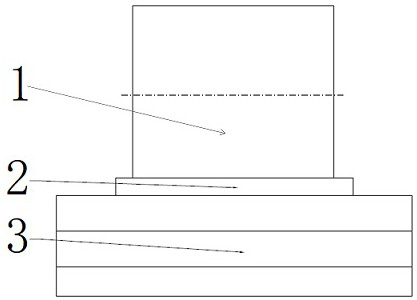

[0048] b) Use pure water and alcohol to clean the lithium niobate wavar 1 fully released stress, and then secure the wafers 1 and the glass strip 2 to the clamp, put it into the clamp, and use the crystal instrument to the crystal graft. Differential deviation, and trimming the waffle crystal direction by machine tool, and then fix the wafers 1 after the repair crystal, the binder is fixed to the reference block 3, and finally at the elbow tail, the resin sheet 4 is bonded to the resin sheet 4, the thick rod Nipped 1 resin strip 5, see Figure 4 with Figure 5 , Obtain lithium tods of lithium niobate to be sliced;

[0049] C) In Example 1, the wafer thickness was obtained from 196.1 μm, the flatness of 10.3 μm, the wafer surface line traces depth 7.6 μm, crystal deviation 0.05 °, theoretical investment of 631 pieces, fragmentation 12, fragment rate 1.90%, see Figure 8 ;

[0050] d) in Example 1;

[0051] E) Same in Example 1, a lithium tap-sonate wafer was ...

Embodiment 3

[0053] a) in Example 1;

[0054] b) Use pure water and alcohol to clean the lithium niobate carbon whose stress is sequentially cleaned, and then secure the wafers 1 and the glass strip 2 to the adhesive, put it into the clamp, and use the crystal instrument to grasp the crystal Deviation, and trimmed the waffle crystal direction by the machine tool, and then fixed to the reference block 3 with the adhesive after the repairing crystal, and finally in the basement block 3, the upper end and both sides are finally in the thickness of the crystal bar. Cohesion 3 resin strips 5, see Image 6 with Figure 7 , Obtain lithium tods of lithium niobate to be sliced;

[0055] C) In the same embodiment, the wafer thickness is 196.2 μm, the flatness of 4.5 μm, the surface line trace depth is 7.1 μm, the crystal deviation is 0.04 °, theoretically invested 611 pieces, fragmentated 10 pieces, fragment rate 1.64%, see Figure 8 ;

[0056] d) in Example 1;

[0057] E) Same in Example 1, a large size u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com