Carbon-free dry material for continuous casting tundish

A continuous casting tundish and dry material technology, applied in the field of refractory materials, can solve the problems of carburization of molten steel, insufficient strength at low and medium temperatures, and poor workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~4

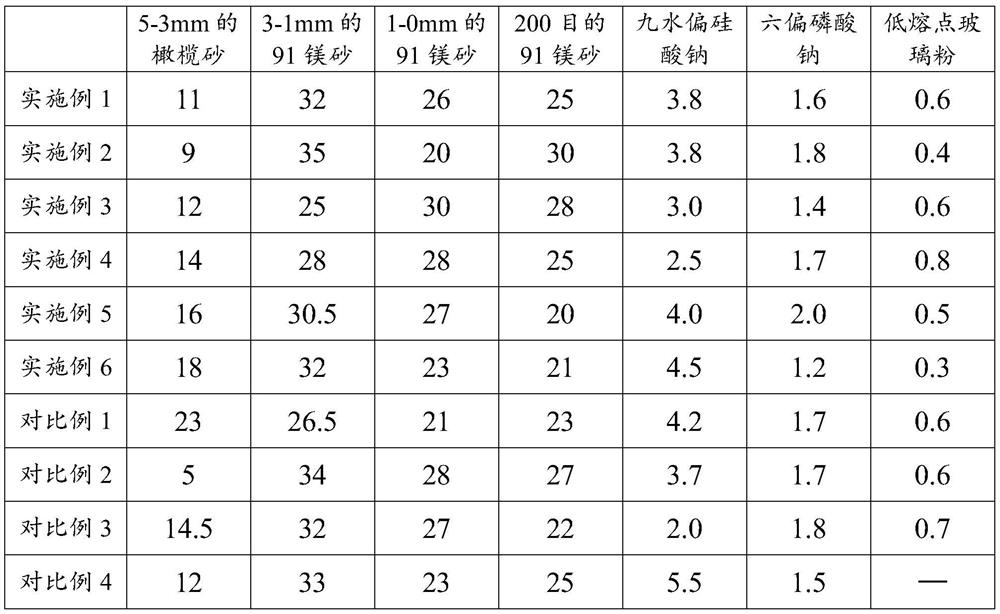

[0023] The mass fractions of raw material components of the carbon-free dry materials for continuous casting tundishes of Examples 1-6 and Comparative Examples 1-4 are shown in Table 1.

[0024] The raw material composition of table 1 embodiment 1~6 and comparative example 1~4, %

[0025]

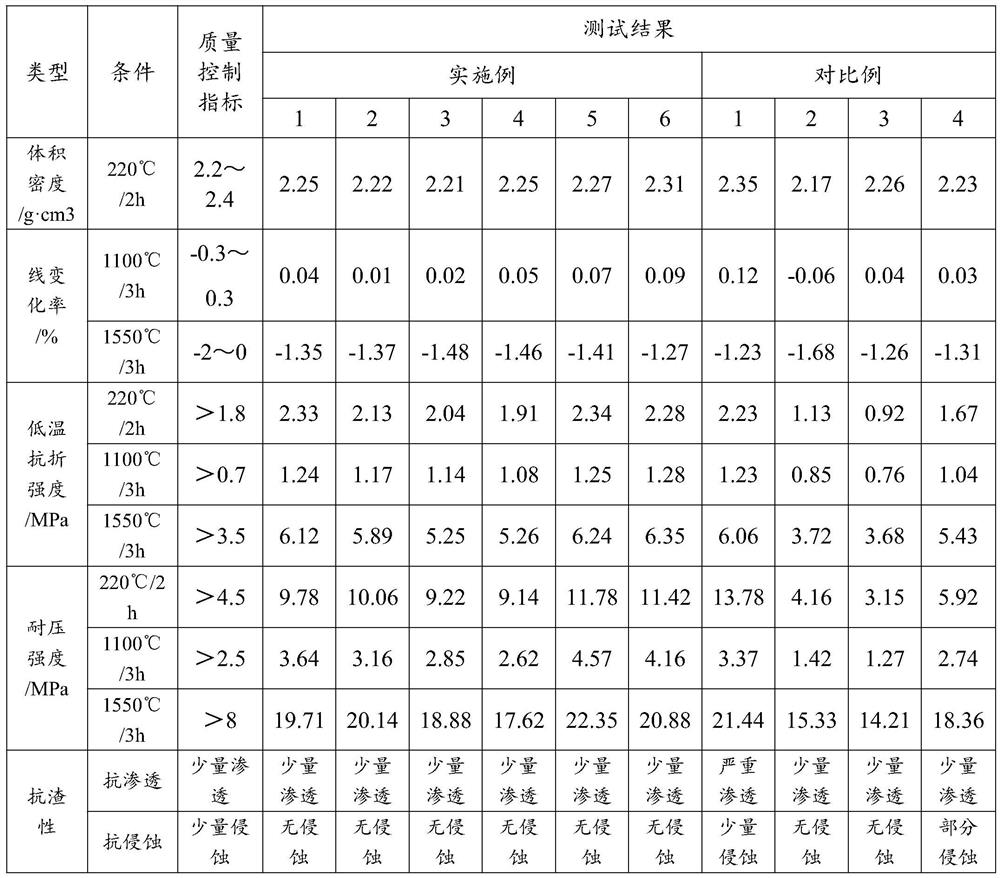

[0026] The carbon-free dry material sample preparation for the continuous casting tundish of Examples 1-6 and Comparative Examples 1-4 was carried out according to GB / T 4513.5. The tests of bulk density, linear change rate, flexural strength and compressive strength shall be carried out according to the test methods in GB / T 4513.6. The slag resistance is determined by the static crucible method, and the penetration resistance and corrosion resistance of the refractory material in the middle section of the crucible are observed. The test results are listed in Table 2.

[0027] From the comparison of the data in Table 1 and Table 2, it can be seen that the carbon-free dry material for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com