Extraction method of dendrobium officinale with antibacterial effect, and compound disinfecting and killing preparation

A technology of Dendrobium officinale and extract, which is applied in the directions of antifungal agents, preparations for skin care, biocides, etc., can solve the problems of few reports, low extraction yield of Dendrobium officinale polysaccharides, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

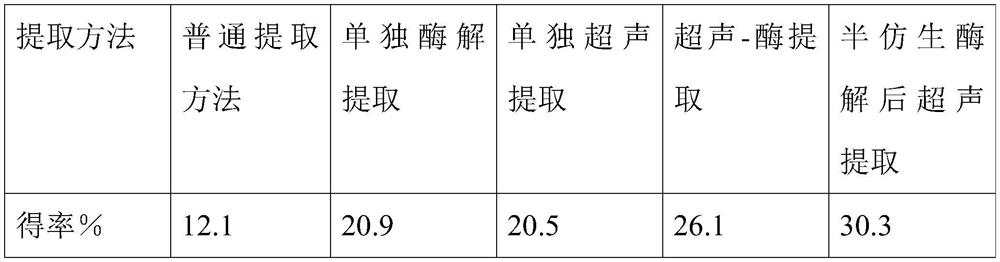

[0036] Example 1 Comparison of separate enzymatic hydrolysis extraction method experiments

[0037] Ref. Preparation of Dendrobium officinale extract. Take Dendrobium officinale, pulverize and pass through a 40-mesh sieve: add 4 times the amount of compound enzyme buffer (pectinase-cellulase-laccase (1-2:1-3:0.5-2.5), add glacial acetic acid solution to adjust the pH value to 4.0), control the enzymatic hydrolysis temperature at 50 °C for 140 min; add drinking water for 5 times, reflux for extraction for 2 h, filter (120 mesh sieve), concentrate the filtrate to a relative density of 1.30 (60 °C), add ethanol to make the solution alcoholic The amount reached 75%, stirred evenly, and after standing for 12 hours, collected the precipitate, evaporated the ethanol, and vacuum-dried at 70°C to obtain the obtained product. The results are shown in Table-1. Compared with the extract obtained by the above extraction method, the method of semi-biomimetic enzymolysis first and then ultr...

Embodiment 2

[0038] Embodiment 2 compares the experiment of ultrasonic extraction method alone

[0039] Ref. Preparation of Dendrobium officinale extract. Take Dendrobium officinale, vacuum dry it at 50°C for 2.5 hours, pulverize it through an 80-mesh sieve, add Dendrobium officinale powder with water at a solid-to-liquid ratio of 1:30, stir and mix, and place it in a stainless steel cylinder to keep it in a closed state. The container is added to the ultrasonic extractor for ultrasonic water bath heating extraction, the ultrasonic power is 300W, the ultrasonic frequency is 45Hz, the extraction temperature is 50-65°C, and the extraction time is 1h-1.5h. The suction filtration mixture is obtained; the suction filtration mixture is centrifuged at 5000-6000r / min for 10-15min to obtain the supernatant extract, concentrated, added with 95% ethanol, alcohol precipitation for 8h, centrifuged, and after the macroporous resin is oversized Dialysis. The results are shown in Table-1. Compared with ...

Embodiment 3

[0040] Example 3 Comparative ultrasonic-enzyme extraction method experiment

[0041] Ref. Preparation of Dendrobium officinale extract. Take Dendrobium officinale, dry at 65°C, pulverize 500 g of it, reflux 3 times with 15 times the weight of 95% ethanol, combine the dregs and dry, add distilled water according to the solid-liquid weight ratio of 1 / 25, ultrasonicate at 400W for 25 minutes, adjust the pH to 6.5, and use a water bath. 45° C., add 2.5% of cellulase and 2.5% of pectinase equivalent to the mass of the medicinal residue, enzymatically hydrolyze for 2.5 hours, and heat up to 55° C. in a water bath. Adjust pH to 6.8, add papain equivalent to 1.5% of the mass of the residue, enzymatically hydrolyze for 2.5h, heat at 92°C for 25min, centrifuge, filter, decolorize, concentrate, dialyze, add 95% ethanol, stand at 25°C for 18h, filter , to dry. The results are shown in Table-1. Compared with the extract obtained by the above extraction method, the method of semi-biomimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com