Preparation method of high-strength high-temperature-resistant polyarylene ether nitrile film

A polyarylene ether nitrile and high temperature-resistant technology is applied in the field of preparation of high-strength and high-temperature-resistant polyarylene ether nitrile films, and can solve problems such as the catalyst is not easily dispersed uniformly, the process is cumbersome and complicated, and the performance of the polyarylene ether nitrile resin is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first embodiment of the present invention discloses a method of preparing high-strength high-temperature polyaryl ether nitrile films, and the specific steps are as follows:

[0035] S1, preparing an aromatic ether nitrile of a phtotrronlonitrile:

[0036] Additional phenol, biphenol, and 2,6-dichlorodylphenyl nitriles are added to the three-necked flask equipped with a thermometer, a moisture, a condensate reflow device, and a mechanical stirring device, and occurs under the catalysis of potassium carbonate. Nuclear reactive reactions gave mixtures, phenol, biphenol, and 2,6-dichlorobenzene and potassium molar ratio of 1: 4.1: 5: 6, press 3: 1 volume ratio to NMP and Toluene, mixed with the above mixture, the mixture and NMP solid-liquid mass ratio of 1: 1, heated to 180 ° C for polymerization, to obtain a hydroxy-block polyaryl ether nitrile; cool the reactor in all mixtures to 80 ° C, add Potassium carbonate, 4-nitroenenenidyl tetrane, NMP solvent, potassium carbonat...

Embodiment 2

[0045] The second embodiment of the present invention discloses a method of preparing high-strength high-temperature polyaryl ether nitrile films, and the specific steps are as follows:

[0046] S1, preparing an aromatic ether nitrile of a phtotrronlonitrile:

[0047] Additional phenol, biphenol, and 2,6-dichlorodylphenyl nitriles are added to the three-necked flask equipped with a thermometer, a moisture, a condensate reflow device, and a mechanical stirring device, and occurs under the catalysis of potassium carbonate. Nuclear reactive reactions gave mixtures, phenol, biphenol, and 2,6-dichlorobenzene and potassium molar ratio of 1: 4.1: 5: 6, press 3: 1 volume ratio to NMP and Toluene, mixed with the above mixture, the mixture and NMP solid-liquid mass ratio of 1: 1, heated to 180 ° C for polymerization, to obtain a hydroxy-block polyaryl ether nitrile; cool the reactor in all mixtures to 80 ° C, add Potassium carbonate, 4-nitroenenenidyl tetrane, NMP solvent, potassium carbona...

Embodiment 3

[0056] The present invention discloses a method for preparing high strength high temperature polyaryl ether nitrile films, and the specific steps are as follows:

[0057] S1, preparing an aromatic ether nitrile of a phtotrronlonitrile:

[0058] Additional phenol, biphenol, and 2,6-dichlorodylphenyl nitriles are added to the three-necked flask equipped with a thermometer, a moisture, a condensate reflow device, and a mechanical stirring device, and occurs under the catalysis of potassium carbonate. Nuclear reactive reactions gave mixtures, phenol, biphenol, and 2,6-dichlorobenzene and potassium molar ratio of 1: 4.1: 5: 6, press 3: 1 volume ratio to NMP and Toluene, mixed with the above mixture, the mixture and NMP solid-liquid mass ratio of 1: 1, heated to 180 ° C for polymerization, to obtain a hydroxy-block polyaryl ether nitrile; cool the reactor in all mixtures to 80 ° C, add Potassium carbonate, 4-nitroenenenidyl tetrane, NMP solvent, potassium carbonate, 4-nitrophenylene ter...

PUM

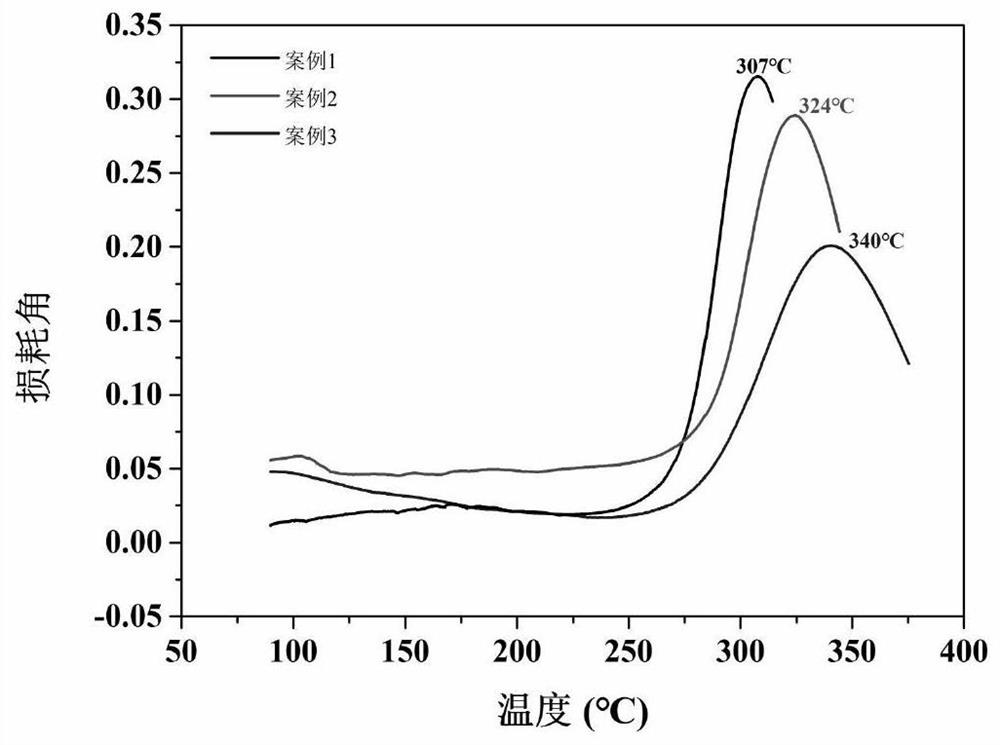

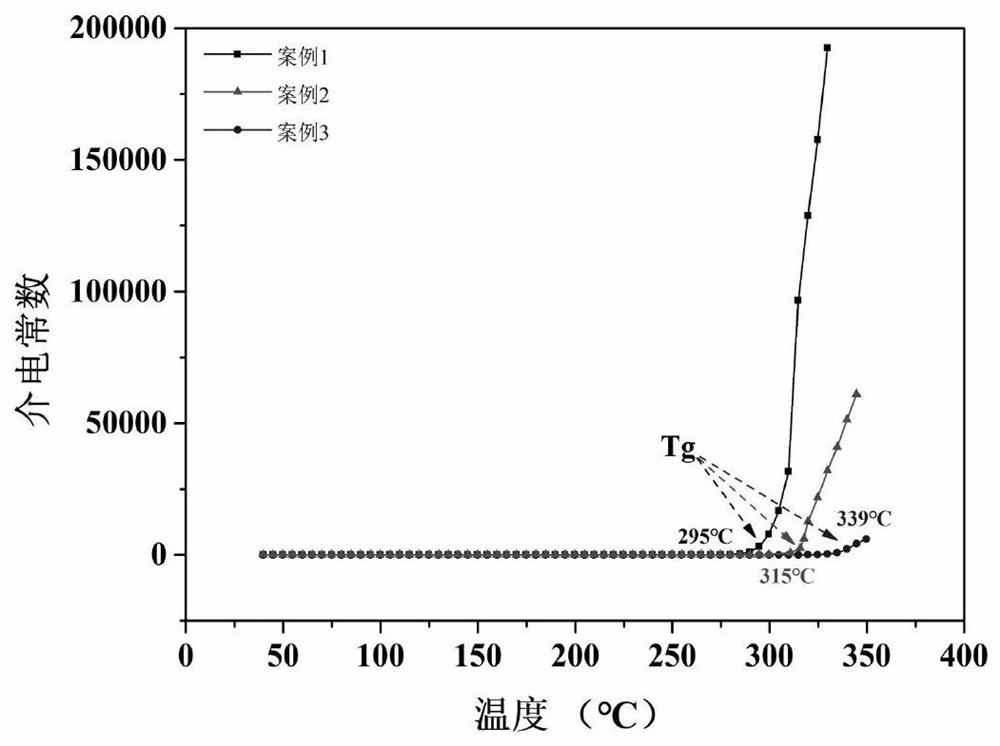

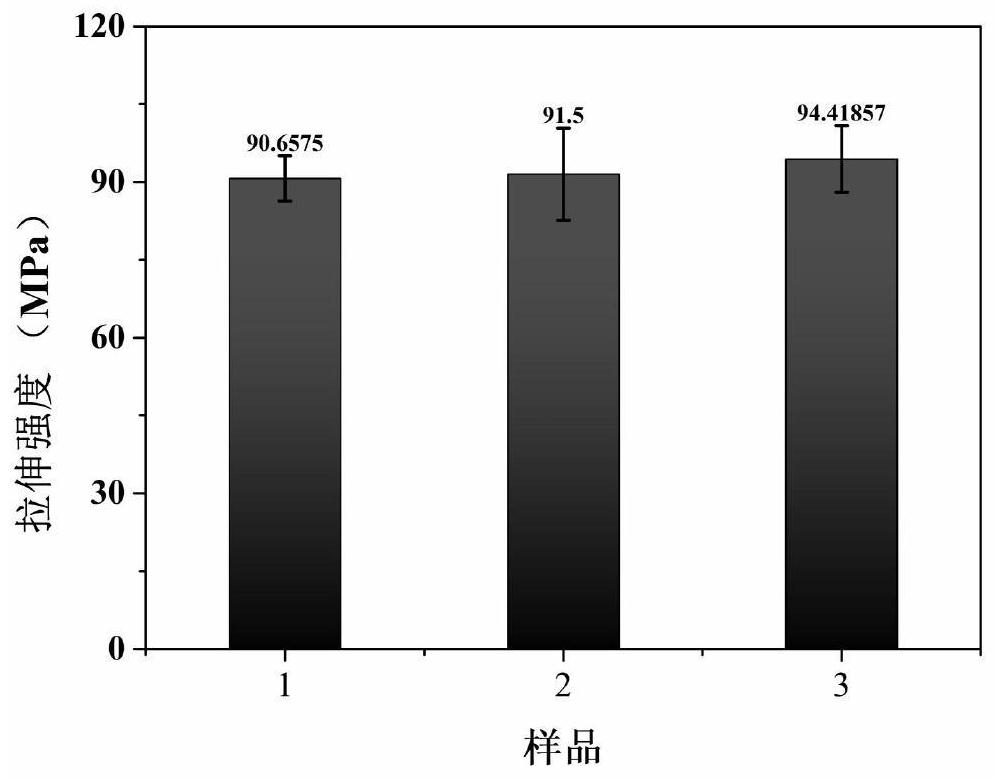

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com