High-performance fluorine-containing cyanate ester resin system and preparation method thereof

A technology of fluorine-containing cyanate ester and cyanate ester resin, which is applied in the field of high-performance fluorine-containing cyanate ester resin system and preparation, and can solve the problems of decreased heat resistance of resin system and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

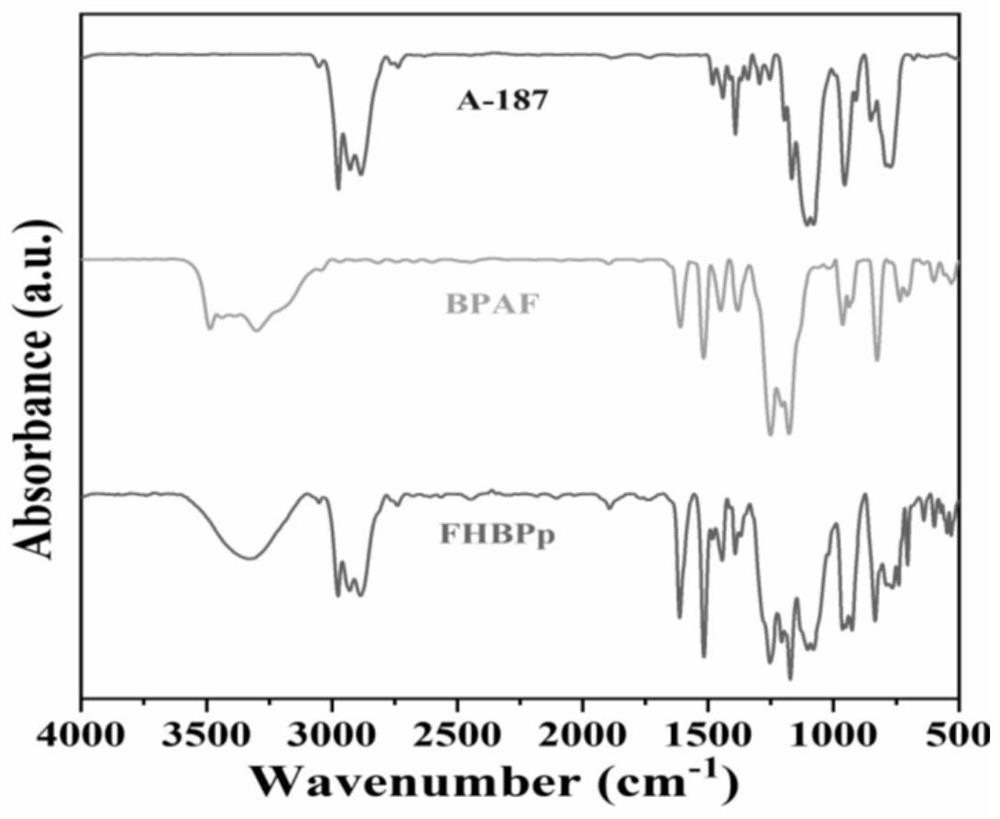

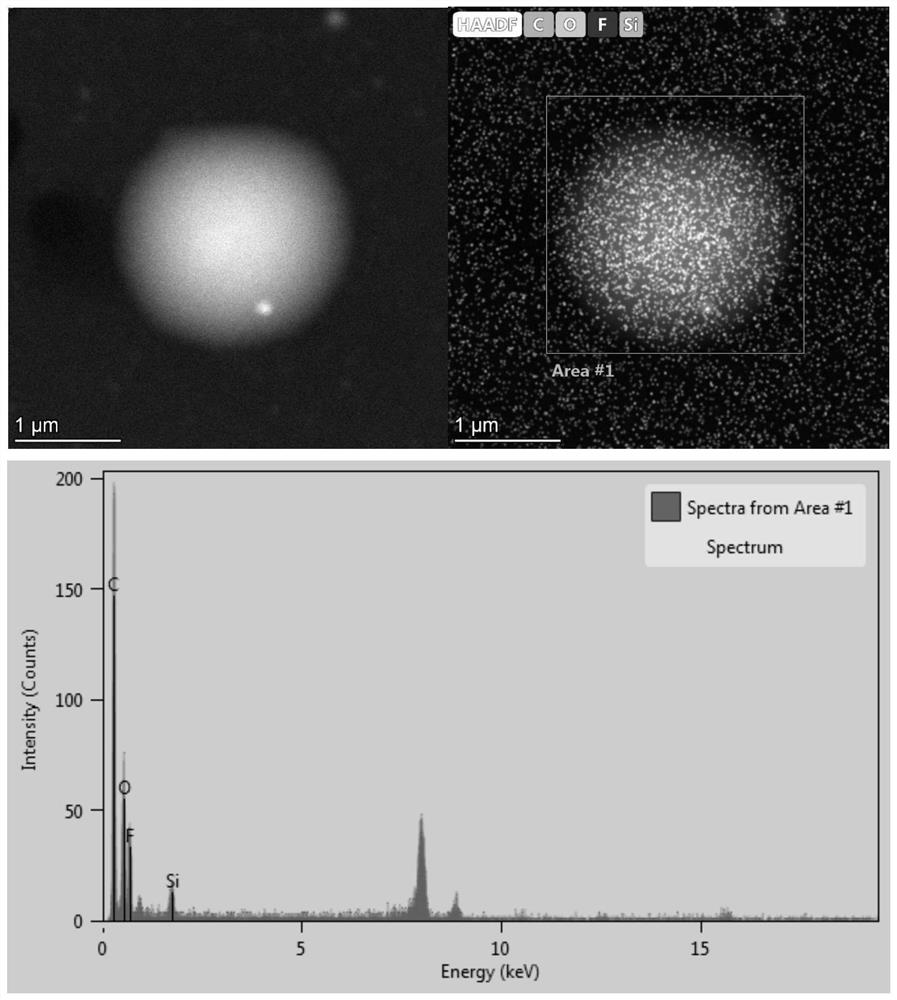

[0037] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0038] Add γ-glycidyl etheroxypropyltriethoxysilane and hexafluorobisphenol A into a three-necked flask at a molar ratio of 3:1, stir under the protection of nitrogen, and control the reaction temperature between 80-150°C During the reaction period, react for 2 to 12 hours until no distillate is produced, and the fluorine-containing hyperbranched polysiloxane is obtained;

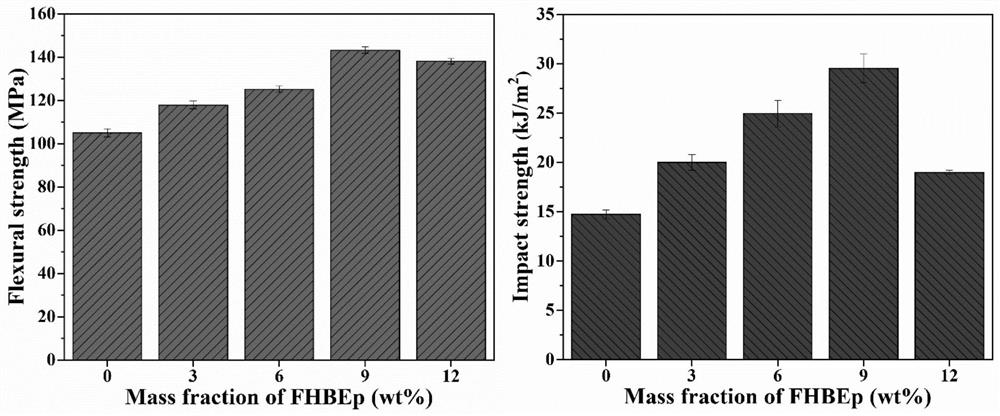

[0039] (2) Preparation of high-performance fluorine-containing cyanate resin system

[0040] After melting 100 parts of bisphenol A cyanate resin at 80°C, add 6 parts of fluorine-containing hyperbranched polysiloxane into it, stir mechanically for 30 minutes, pour it into a preheated mold, and heat it at 120°C In a vacuum oven, after evacuating for 30 minutes, put it into a blast drying oven for staged heating and curing. The curing process is 160°C / 2h+190°C / 3h+220°C / 2h, cooling, demoulding, and then curing at 240°C After 4 hours o...

Embodiment 2

[0042] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0043] Add γ-glycidyl etheroxypropyltriethoxysilane and hexafluorobisphenol A into the three-necked flask at a molar ratio of 2:1, stir under the protection of nitrogen, and control the reaction temperature between 80-150°C During the reaction period, react for 2 to 12 hours until no distillate is produced, and the fluorine-containing hyperbranched polysiloxane is obtained;

[0044] (2) Preparation of high-performance fluorine-containing cyanate resin system

[0045] Melt 100 parts of bisphenol A cyanate resin at 80°C, add 9 parts of fluorine-containing hyperbranched polysiloxane into it, heat up to 120°C, stir mechanically for 1 hour, and pour it into a preheated mold , in a vacuum oven at 120°C, after evacuating for 1 hour, put it into a blast drying oven for step-by-step heating and curing. Post-treatment at 240°C for 4 hours to obtain a high-performance fluorine-containing cyanate resin system.

Embodiment 3

[0047] (1) Preparation of fluorine-containing hyperbranched polysiloxane

[0048] Add γ-glycidyl etheroxypropyl triethoxysilane and hexafluorobisphenol A into a three-necked flask at a molar ratio of 1.8:1, stir under the protection of nitrogen, and control the reaction temperature between 80-150°C In between, react for 2 to 12 hours until no distillate is produced, and the fluorine-containing hyperbranched polysiloxane is obtained;

[0049] (2) Preparation of high-performance fluorine-containing cyanate resin system

[0050] Melt 100 parts of bisphenol A cyanate resin at 80°C, add 12 parts of fluorine-containing hyperbranched polysiloxane into it, heat up to 120°C, stir mechanically for 40 minutes, and pour it into a preheated mold , in a vacuum oven at 120°C, after evacuating for 2 hours, put it into a blast drying oven for staged heating and curing. The curing process is 160°C / 2h+190°C / 3h+220°C / 2h. Post-treatment at 240°C for 4 hours to obtain a high-performance fluorine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com