Migration-resistant environment-friendly plasticizer with micro-crosslinking structure and preparation method of same

An environmentally friendly plasticizer and micro-crosslinking technology, applied in the field of plasticizers, can solve the problems of no health problems, poor temperature resistance, low cost, etc., and achieve good migration resistance, not easy to move, and prevent migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

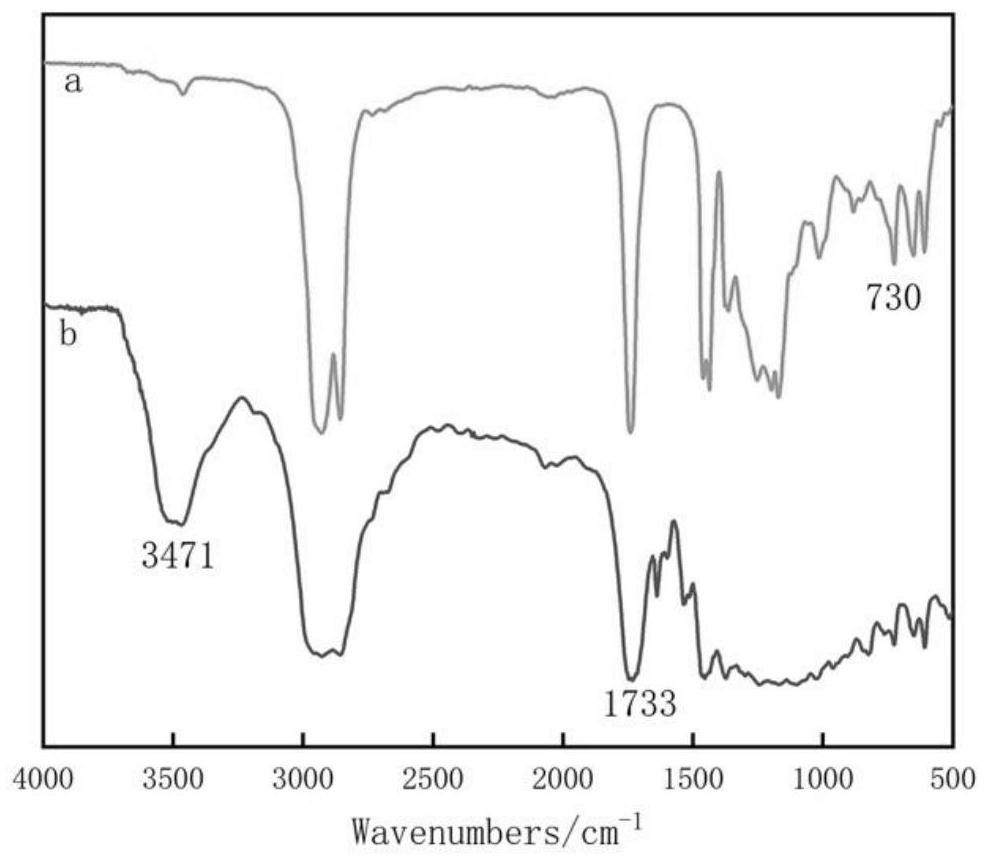

Image

Examples

Embodiment 1

[0042] A migration-resistant micro-crosslinked structure environment-friendly plasticizer, in parts by mass, its raw material formula components are as follows:

[0043]

[0044] A preparation method of a migration-resistant micro-crosslinked structure environment-friendly plasticizer, comprising the following steps:

[0045] 1) In terms of parts by mass, take 30 parts of epoxy soybean oil, 20 parts of polytrimethylene sebacate and adipate polyester 1:1 mixture, 6 parts of dipropylene glycol methyl ether acetate, use 120r / Stir at a speed of 1 min, heat to 90°C, add 8 parts of ternary chlorinated vinegar, cellulose acetate butyrate, chlorinated paraffin-70, antioxidant 168 mixture, keep warm for 1 hour and cool down to 70°C, add 2 parts of PEG -2000, 4 parts of isophorone diisocyanate, stirred for 0.5h;

[0046] 2) Add 30 parts of chlorinated fatty acid methyl esters to the reactor after the reaction in step 1), raise the temperature to 80° C., keep it warm for 1 hour, and...

Embodiment 2

[0054] A migration-resistant micro-crosslinked structure environment-friendly plasticizer, in parts by mass, its raw material formula components are as follows:

[0055]

[0056] A preparation method of a migration-resistant micro-crosslinked structure environment-friendly plasticizer, comprising the following steps:

[0057] (1) Take 25 parts of epoxy fatty acid methyl ester, 16 parts of polytrimethylene sebacate, 6 parts of dipropylene glycol methyl ether acetate, stir at a speed of 120r / min, heat to 90°C, and then add 8 parts The mixture of tribasic chlorinated vinegar, cellulose acetate butyrate, chlorinated paraffin-70, and antioxidant 168 was kept warm for 1 hour and then cooled to 65°C, and 4 parts of polyethylene glycol and 6 parts of toluene diisocyanate were added and stirred 0.5h;

[0058] (2) Add 35 parts of chlorinated fatty acid methyl esters to the reactor after the reaction in step (1), heat up to 70° C., keep warm for 1 hour, and distill under reduced pres...

Embodiment 3

[0061] A migration-resistant micro-crosslinked structure environment-friendly plasticizer, in parts by mass, its raw material formula components are as follows:

[0062]

[0063] The preparation method of this embodiment comprises the following steps:

[0064] (1) Take 50 parts of epoxy fatty acid methyl ester, 10 parts of adipic acid polyester, 6 parts of dipropylene glycol methyl ether acetate, stir at a speed of 120r / min, heat to 100°C, and then add 10 parts of The mixture of tribasic chlorinated vinegar, cellulose acetate butyrate, chlorinated paraffin-70, and antioxidant 168 was kept warm for 1 hour and then cooled to 70°C. 3 parts of polytetrahydrofuran diol and 6 parts of toluene diisocyanate were added and stirred for 0.5 h;

[0065] (2) Add chlorinated fatty acid methyl esters to the reaction kettle after the reaction in step (1), heat up to 80°C, keep warm for 1 hour, and distill under reduced pressure to obtain the final migration-resistant environmental protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com