Two-component waterborne epoxy silver powder paint as well as preparation method and application thereof

A technology of water-based epoxy resin and epoxy silver, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor weather resistance of epoxy phosphate, peeling of polystyrene resin layer, and hindering the diffusion of water molecules. , to achieve the effect of good sag resistance, lower price and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

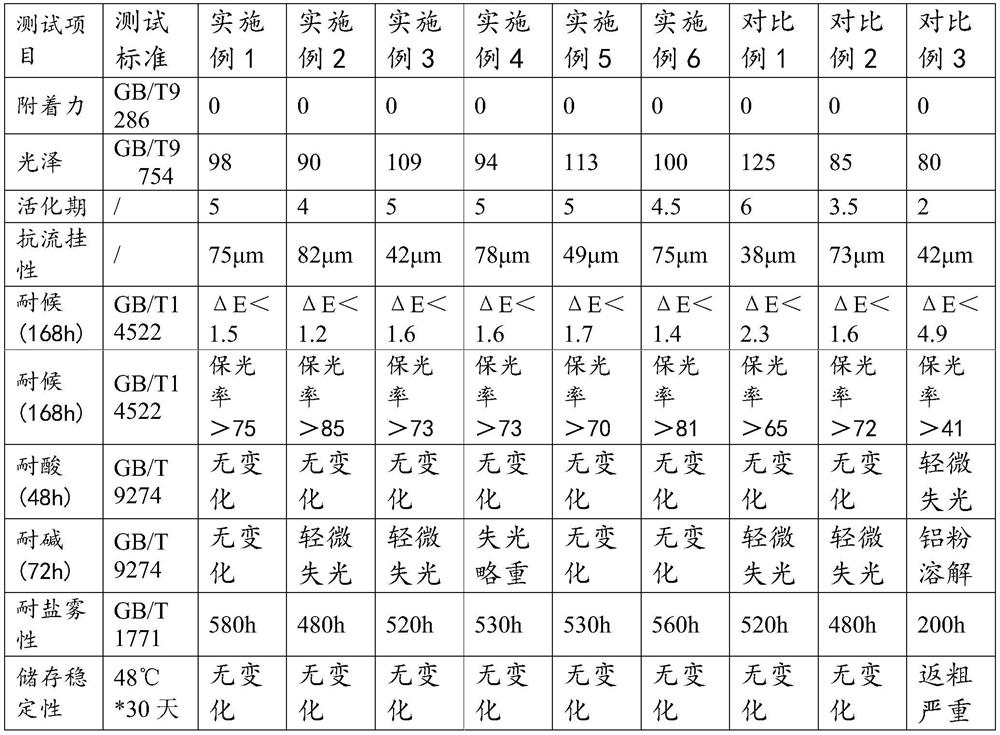

Examples

specific Embodiment approach

[0033] The preparation method of the two-component waterborne epoxy silver powder paint described in the following specific embodiments may further comprise the steps:

[0034](1) Add water-based epoxy resin dispersion, liquid epoxy resin, and anti-sagging resin in proportion under stirring, and disperse evenly to obtain mixed solution a; prepare sodium lithium magnesium silicate solution in proportion; prepare passivation in proportion Aluminum-silver paste: add sodium lithium magnesium silicate solution and passivated aluminum-silver paste to mixed liquid a, and disperse evenly; then add additives and deionized water in turn, disperse evenly, and after passing the test, the main agent is obtained.

[0035] (2) Add the fatty amine adduct in proportion and stir, disperse the cosolvent, auxiliary agent and deionized water into the fatty amine adduct, stir evenly, and obtain the curing agent after passing the inspection.

[0036] (3) Mix the main agent and the curing agent in pr...

Embodiment 1

[0038] A kind of two-component waterborne epoxy silver powder paint of the embodiment of the present invention, the two-component waterborne epoxy silver powder paint of the present embodiment comprises main agent and curing agent, wherein, main agent comprises the component of following percentage by weight: 50% Waterborne epoxy resin dispersion EPIKOTE 3523-WH-53, 5% liquid epoxy resin Beckopox EP 147w, 5% anti-sag resin SETAQUA 6803, 20% sodium lithium magnesium silicate solution, 15% passivation aluminum silver paste, 2 % wetting agent BYK-348, 1.5% silane coupling agent A-187, 1.5% anti-flash rust additive ASCONIUM-142DA; curing agent includes the following components in weight percentage: 40% aliphatic amine adduct curing agent Epikure 8545-W-52, 2.5% co-solvent DPNB and 2.5% co-solvent PM, 1% defoamer Airex 902W, 1% thickener Reholate 299 and 1% thickener ViscoPlus 3060, the balance is deionized water.

[0039] Wherein, the weight ratio of main agent and curing agent is...

Embodiment 2

[0041] A kind of two-component waterborne epoxy silver powder paint of the embodiment of the present invention, the two-component waterborne epoxy silver powder paint of the present embodiment comprises main agent and curing agent, wherein, main agent comprises the component of following percentage by weight: 40% Waterborne epoxy resin dispersion EPIKOTE 3523-WH-53, 8% liquid epoxy resin Beckopox EP 147w, 6% anti-sag resin SETAQUA 6803, 20% sodium lithium magnesium silicate solution, 20% passivation aluminum silver paste, 3 % wetting agent BYK-348, 1.5% silane coupling agent A-187, 1.5% anti-flash rust additive ASCONIUM-142DA; curing agent includes the following components in weight percentage: 40% aliphatic amine adduct curing agent Epikure 8545-W-52, 2.5% co-solvent DPNB and 2.5% co-solvent PM, 1% defoamer Airex 902W, 1% thickener Reholate 299 and 1% thickener ViscoPlus 3060, the balance is deionized water.

[0042] Wherein, the weight ratio of main agent and curing agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com