Preparation method and application of transition metal single atom and nitrogen and phosphorus doped carbon spheres

A transition metal, nitrogen and phosphorus technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of uncontrollable transition metal content and types of catalysts, low oxygen reduction performance of catalysts, complex processes, etc., to achieve environmental friendliness and high power Density, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

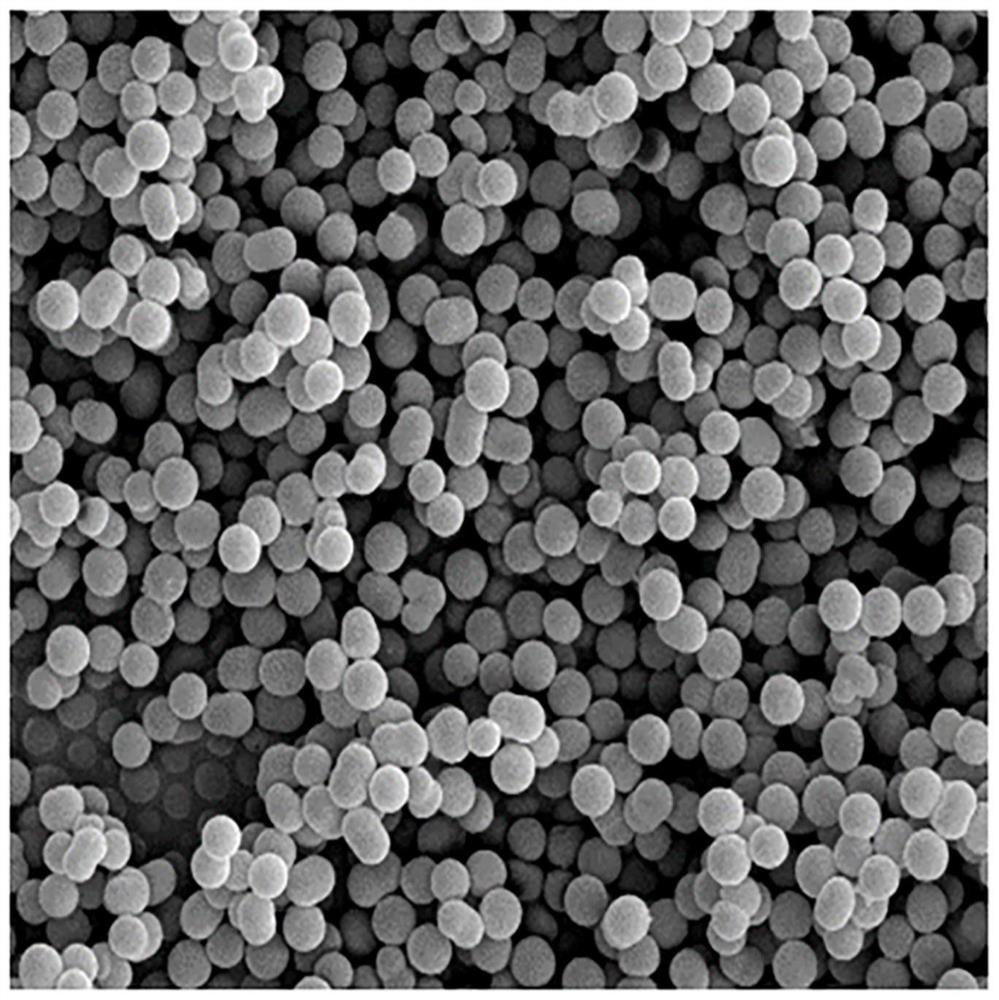

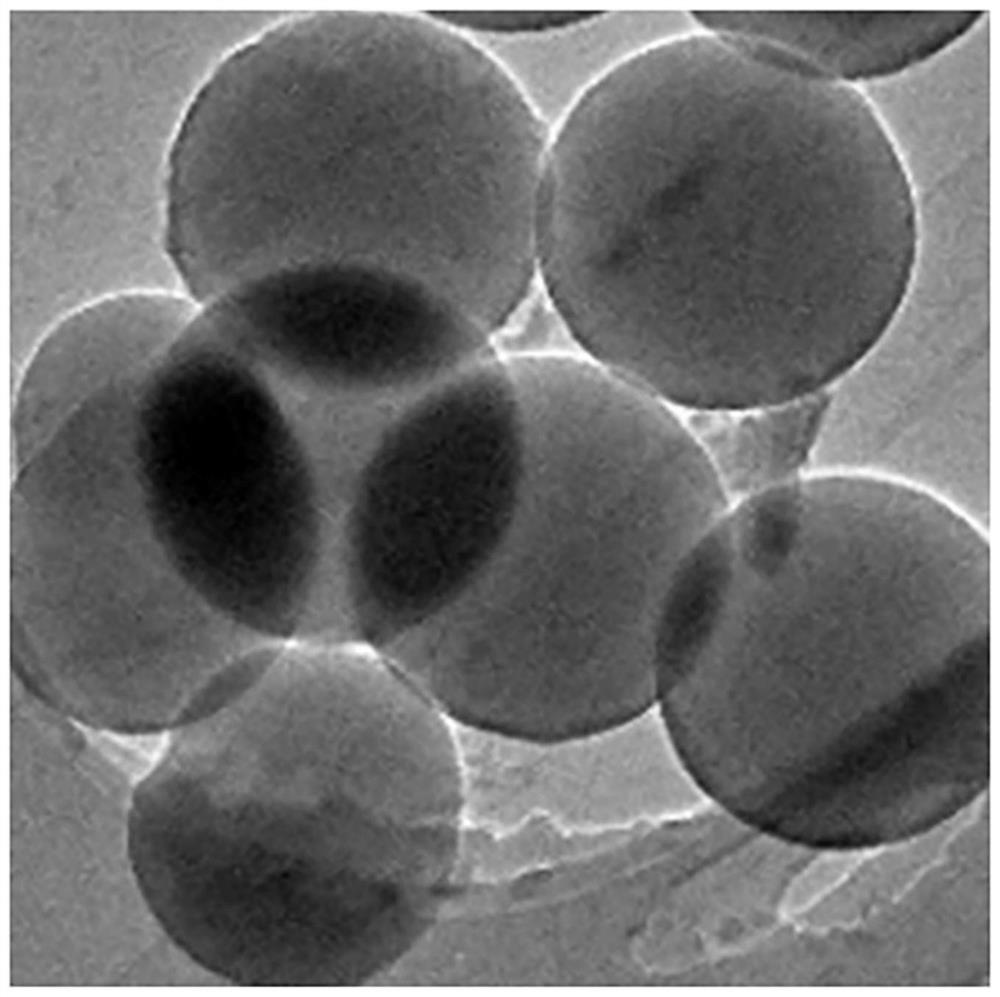

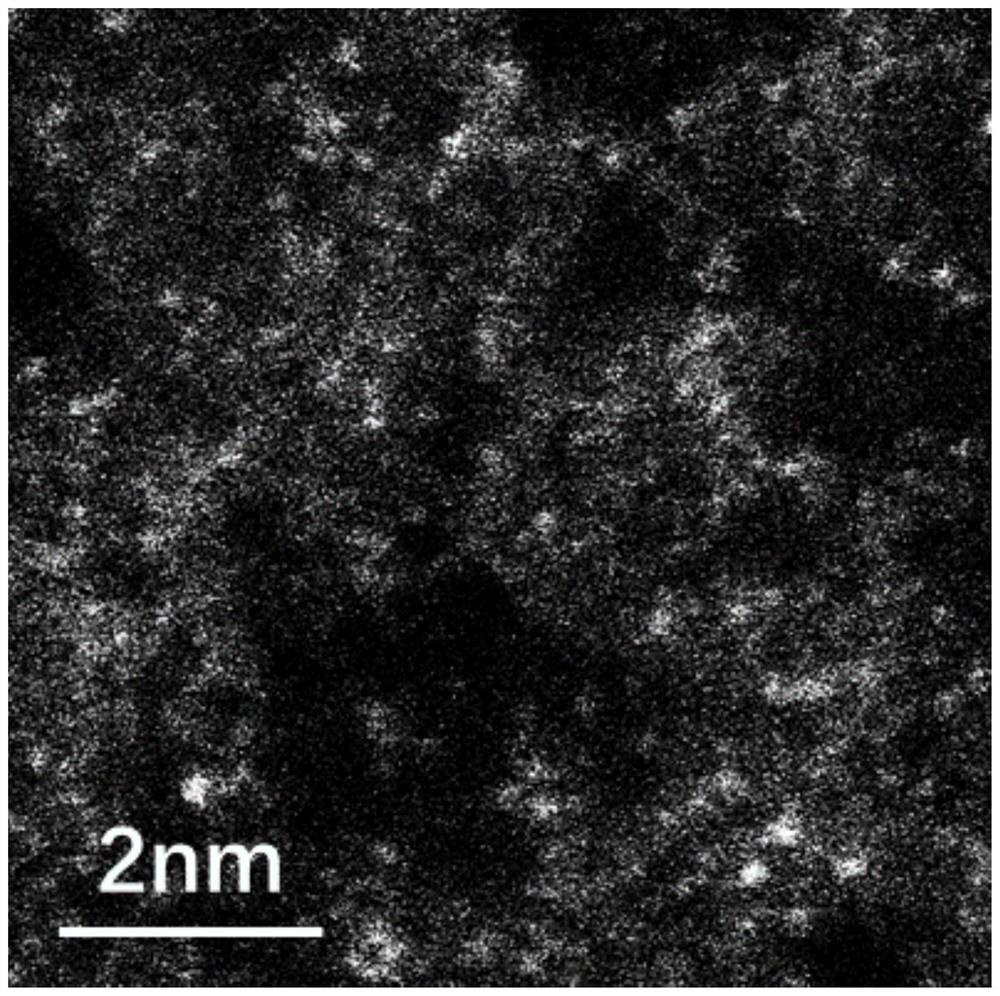

[0041] The preparation of a transition metal single atom and nitrogen and phosphorus co-doped carbon spheres is carried out in the following steps:

[0042] (1) Add 100ml of acetonitrile solution into a 250ml capacity beaker, then add 0.6g of hexachlorotripolyphosphazene and 0.4g of phloroglucinol, after it dissolves, add 1mg of manganese acetate and 2ml of triethylamine, then place the beaker In an ultrasonic cleaner, conduct ultrasonic reaction at a constant temperature of 40°C for 30 minutes (ultrasonic power is 200 W) and centrifuge the precipitate under the condition that the rotation speed is 5000 rpm and the time is 5 minutes. The finished precipitate was dried in an oven at 50°C for 6 hours to obtain a catalyst template.

[0043] (2) Put the catalyst template into the porcelain boat, then put it into the tube furnace, and vacuum the tube furnace to make the vacuum degree reach 9×10 -2 Pa, and then 60sccm of nitrogen gas was introduced, and then heated to 200°C, 400°C, a...

specific Embodiment approach 2

[0045] The preparation of a transition metal single atom and nitrogen and phosphorus co-doped carbon spheres is carried out in the following steps:

[0046] (1) Add 100ml of acetonitrile solution into a 250ml capacity beaker, then add 0.6g of hexachlorotripolyphosphazene and 0.4g of phloroglucinol, after it dissolves, add 5mg of ferric nitrate and 2ml of triethylamine, and then put the beaker Place it in an ultrasonic cleaner, conduct ultrasonic reaction at a constant temperature of 40°C for 30 minutes (ultrasonic power is 200 W), and then centrifuge the precipitate at a speed of 5000 rpm for 5 minutes. The precipitate after centrifugation was dried in an oven at 50° C. for 6 hours to obtain a catalyst template.

[0047] (2) Put the catalyst template into the porcelain boat, then put it into the tube furnace, and vacuum the tube furnace to make the vacuum degree reach 1×10 -3 Pa, and then 70sccm of argon gas was introduced, and then heated to 200°C, 400°C, and 600°C at a rate...

specific Embodiment approach 3

[0049] The preparation of a transition metal single atom and nitrogen and phosphorus co-doped carbon spheres is carried out in the following steps:

[0050] (1) Add 100ml of acetonitrile solution into a 250ml capacity beaker, then add 0.3g of hexachlorotripolyphosphazene and 0.2g of phloroglucinol, after it dissolves, add 1mg of cobalt nitrate and 1ml of triethylamine, and then put the beaker Place in an ultrasonic cleaner, conduct an ultrasonic reaction at a constant temperature of 40°C (ultrasonic power: 180W) for 30 minutes, and then centrifuge the precipitate at a speed of 5000 rpm for 5 minutes. Centrifuge the obtained precipitate three times with ethanol and deionized water respectively. The precipitate after centrifugation was dried in an oven at 50° C. for 6 hours to obtain a catalyst template.

[0051] (2) Put the catalyst template into the porcelain boat, then put it into the tube furnace, and vacuum the tube furnace to make the vacuum degree reach 9×10 -2 Pa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com