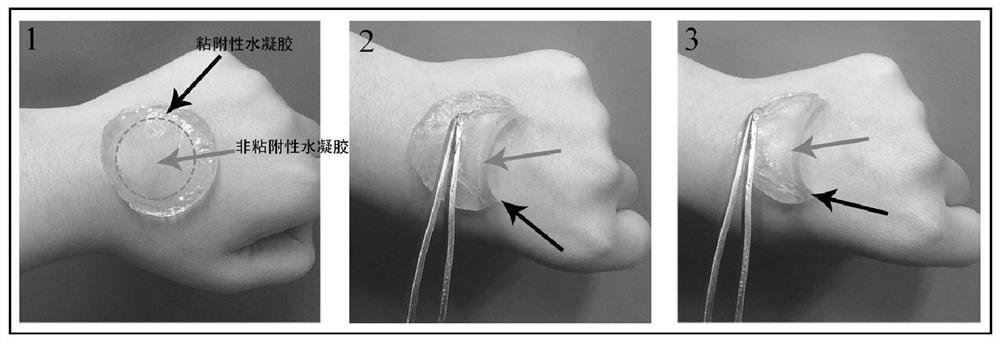

Adhesive-non-adhesive integrated hydrogel as well as preparation method and application thereof in wound repair

A hydrogel, non-adhesive technology, used in medical science, bandages, etc., to achieve good mechanical properties, good application prospects, and good water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

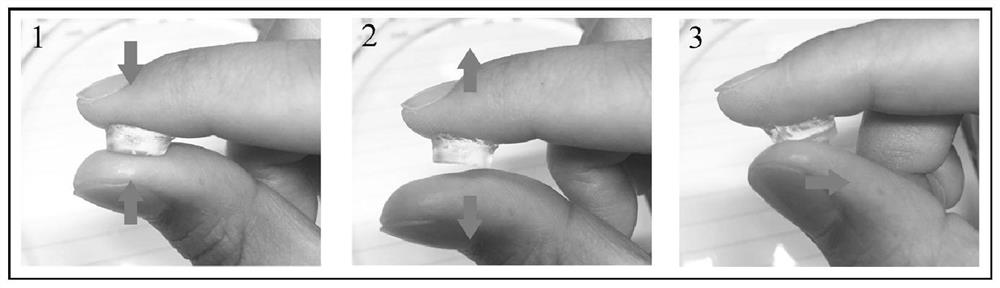

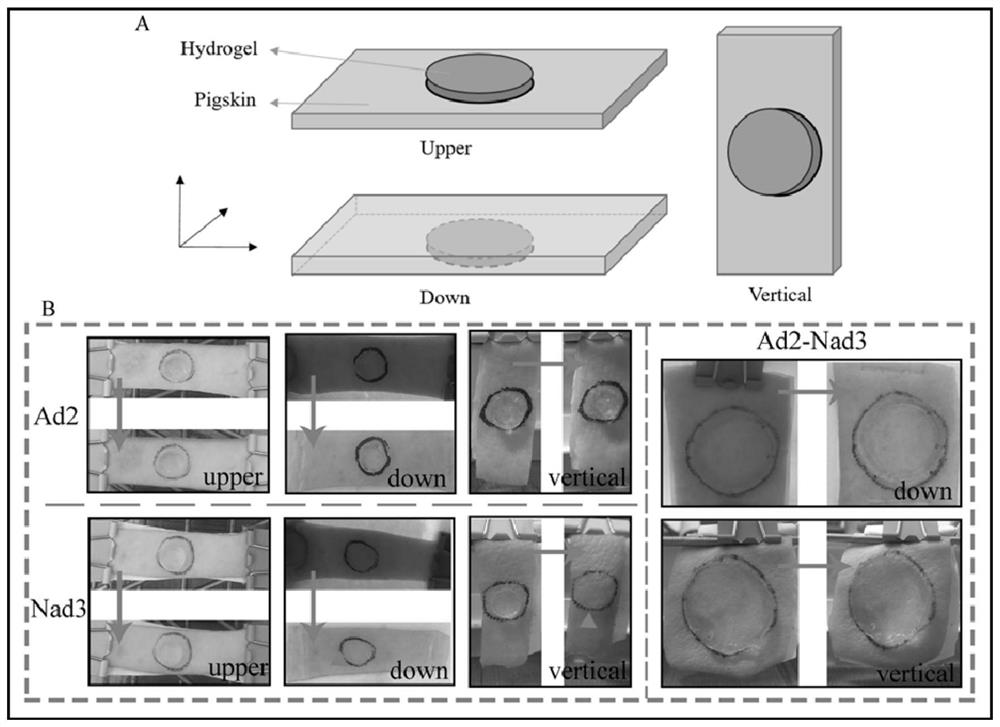

[0052] The present invention also provides a method for preparing an adhesion-non-adhesion integrated hydrogel, which specifically includes the following steps:

[0053] (1) Prepare the precursor solution of the hydrogel for the adhesion part, that is, prepare the base substance with a double bond containing 1 to 30% of the mass fraction, 1 to 50% of the monomer with a double bond, and 0.01 to 5% of the Mixed aqueous solution A of initiator, 0.005-0.5% cross-linking agent, 0.1-30% polysaccharide.

[0054] (2) Prepare the precursor solution of the non-adhesive part of the hydrogel, that is, prepare a monomer with a double bond with a mass fraction of 1 to 30%, a zwitterionic monomer with a double bond with a mass fraction of 1 to 50%, and 0.01 to 5% A mixed aqueous solution B of initiator, 0.005-0.5% cross-linking agent, and 0.1-40% polysaccharide.

[0055] (3) Inject the mixed solution A of step (1) into the mold, and stand still at 0-35° C. for 5-120 minutes to form a hydrog...

Embodiment 1

[0063] (1) Weigh 400mg of acrylamide, 100mg of acrylylated adenine, 25mg of ammonium persulfate, 0.5mg of N,N'-bisacrylamide, 5mg of chitosan, and 35mg of oxidized hyaluronic acid in a centrifuge tube, and add 2.5mL Distilled water, vortex at room temperature to dissolve, and ultrasonically remove air bubbles in the mixed solution. Transfer the mixed solution to the annular groove formed concentrically between the cylinder and the barrel, let it stand for 5 minutes, and take out the cylinder to form a ring-shaped hydrogel.

[0064] (2) Weigh 350mg acrylamide, 150mg 2-methacryloyloxyethyl phosphorylcholine, 25mg ammonium persulfate, 0.5mg N,N'-bisacrylamide, 20mg chitosan, 7mg oxidized hyaluronic acid in Add 2.5 mL of distilled water to the centrifuge tube, vortex to dissolve at room temperature, and remove air bubbles in the solution by ultrasonication. The mixed solution was poured inside the ring-shaped hydrogel of (1) in this embodiment, and left to stand for 5 minutes to ...

Embodiment 2

[0067] (1) Weigh 400mg of acrylamide, 100mg of acrylylated adenine, 25mg of ammonium persulfate, 0.5mg of N,N'-bisacrylamide, 15mg of carboxymethyl chitosan, and 35mg of oxidized dextran in a centrifuge tube, Add 2.5 mL of distilled water, vortex at room temperature to dissolve, and ultrasonically remove the air bubbles in the mixed solution. Transfer the mixed solution to the annular groove of the mold formed concentrically between the cylinder and the barrel, let it stand for 5 minutes, take out the cylinder, and form a ring-shaped hydrogel.

[0068] (2) Weigh 350mg of acrylamide, 150mg of 2-methacryloyloxyethyl phosphorylcholine, 25mg of ammonium persulfate, 0.5mg of N,N'-bisacrylamide, 40mg of carboxymethyl chitosan, 7mg of oxidized glucose Add 2.5 mL of distilled water to the polysaccharide in a centrifuge tube, vortex to dissolve at room temperature, and remove bubbles in the solution by ultrasonication. The mixed solution was poured inside the ring-shaped hydrogel of (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com