Fast-firing non-phosphorus low-silicon gunning mix and preparation method thereof

A fast-burning, gunning material technology, applied in the field of refractory materials, can solve problems such as increased maintenance cost, molten steel pollution, and quality impact, and achieve the effect of ensuring sintering strength, protecting gunning parts, and ensuring purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

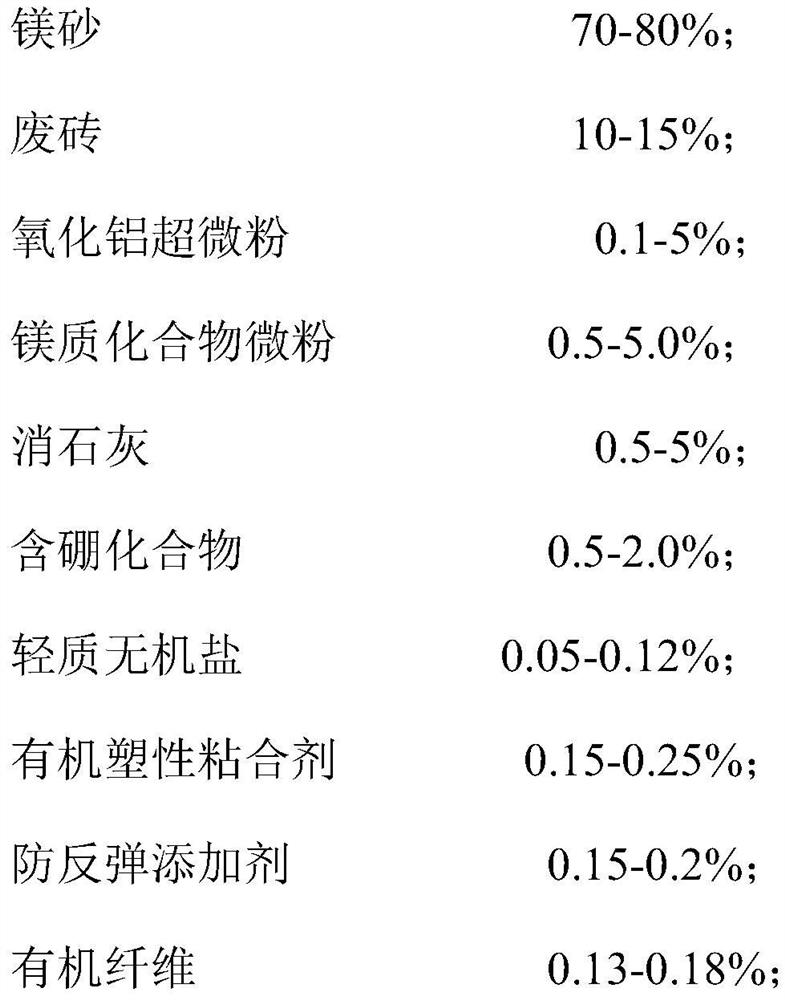

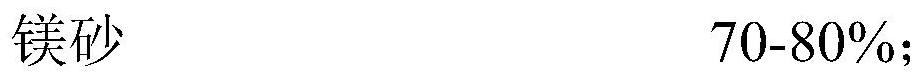

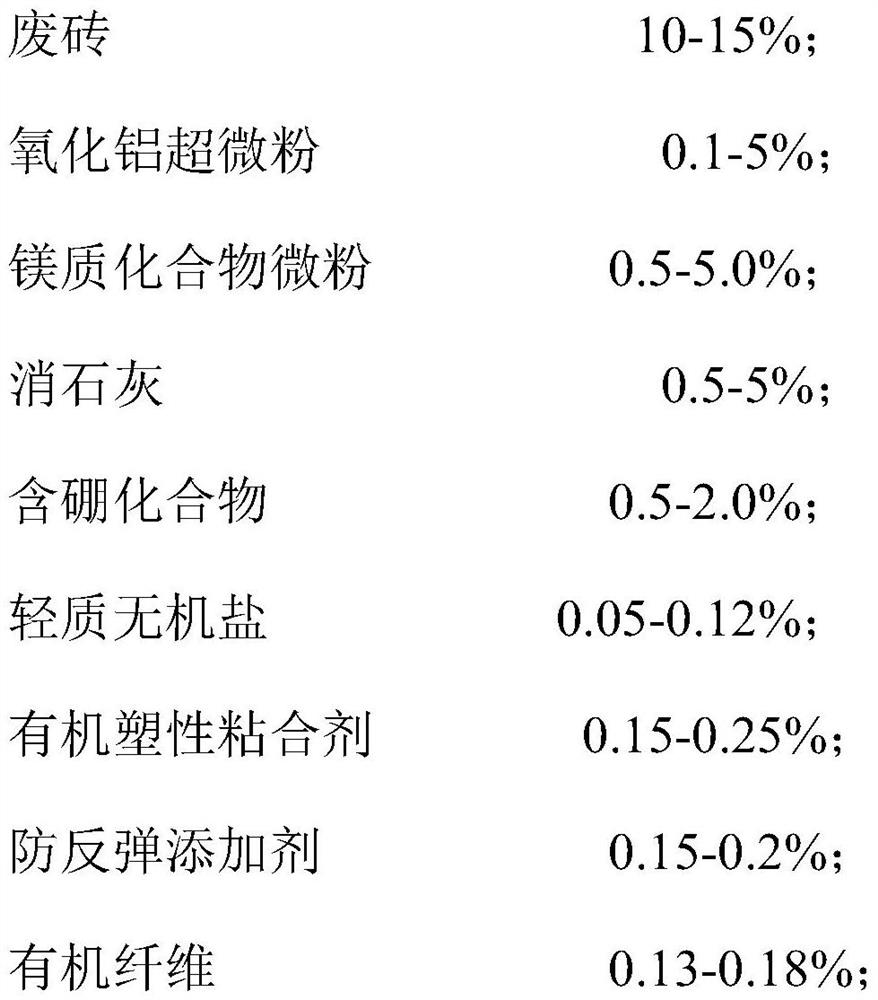

Embodiment 1

[0030] This embodiment provides a fast-burning non-phosphorus and low-silicon gunning material, which is composed of the following components in weight percentage: 24% of sintered magnesia with a particle size of 1-3mm as raw material, and sintered magnesia with a particle size of 0.088-0.999mm 26% (93.5% by mass of MgO), 24% of fine powder of sintered magnesia whose particle size is less than 0.063mm (96.5% by mass of MgO), 15% of waste magnesia bricks with a particle size of 0.1-3mm, calcined 3.0% alumina micropowder, 2.5% lightly burned magnesia powder, 3.4% slaked lime, 1.5% industrial boric acid, 0.1% light inorganic salt, 0.17% organic plastic binder, 0.2% anti-rebound additive, 0.13% organic fiber.

Embodiment 2

[0032] This embodiment provides a fast-burning non-phosphorus and low-silicon gunning material, which is composed of the following components in weight percentage: 22% of sintered magnesia with a particle size of 1-3mm, and sintered magnesia with a particle size of 0.088-0.999mm 30% (95% by mass of MgO), 23.5% of sintered magnesia fine powder with a particle size of less than 0.063mm (97% by mass of MgO), 14% of waste magnesia bricks with a particle size of 0.1-3mm, calcined Alumina fine powder 2.5%, magnesium carbonate 1.0%, lightly burned magnesia powder 1.0%, slaked lime 4.4%, industrial boric acid 1.0%, light inorganic salt 0.05%, organic plastic binder 0.25%, anti-rebound additive 0.15%, organic Fiber 0.15%.

Embodiment 3

[0034] This embodiment provides a fast-burning non-phosphorus and low-silicon gunning material, which is composed of the following components in weight percentage: 20% of sintered magnesia with a particle size of 1-3mm as raw material, and sintered magnesia with a particle size of 0.088-0.999mm 28% (92.5% by mass of MgO), 23% of fused magnesia fine powder with a particle size of less than 0.063mm (96.8% by mass of MgO), magnesia spinel waste bricks with a particle size of 0.1-3mm 17 %, calcined alumina micropowder 1.5%, lightly burned magnesia powder 1.0%, magnesium chloride 1.5%, magnesium sulfate 1.5%, slaked lime 4.1%, sodium borate 1.8%, light inorganic salt 0.12%, organic plastic binder 0.15%, Anti-rebound additive 0.15%, organic fiber 0.18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com