Vanadium oxide composite high-nickel ternary positive electrode material, and preparation method and application thereof

A cathode material, a technology of vanadium oxide, applied in the field of vanadium oxide composite high-nickel ternary cathode material and its preparation, can solve the problems of hidden danger, poor material stability, high content, and achieve mild conditions, strong practicability and high cycle. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a vanadium oxide composite high-nickel ternary positive electrode material, comprising the following steps:

[0032] (1) 1g of high-nickel ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Mix evenly with 0.05 g of ammonium metavanadate, and mix well by ball milling for 1 hour, wherein the rotational speed of the ball mill is 400 rpm.

[0033] (2) Then put the ball-milled material into a tube furnace, heat up to 450° C. for sintering for 6 hours in an oxygen atmosphere, and the heating rate is 5° C. / min to obtain a vanadium oxide composite lithium-ion battery high-nickel ternary positive electrode material.

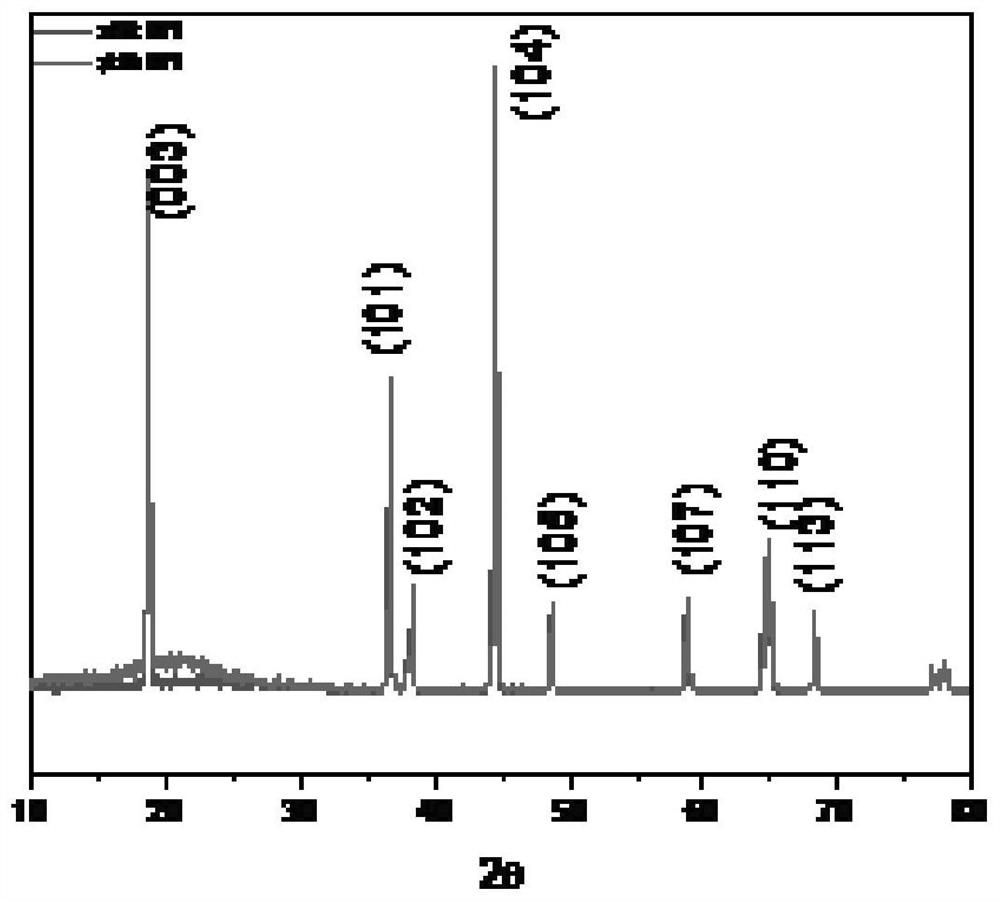

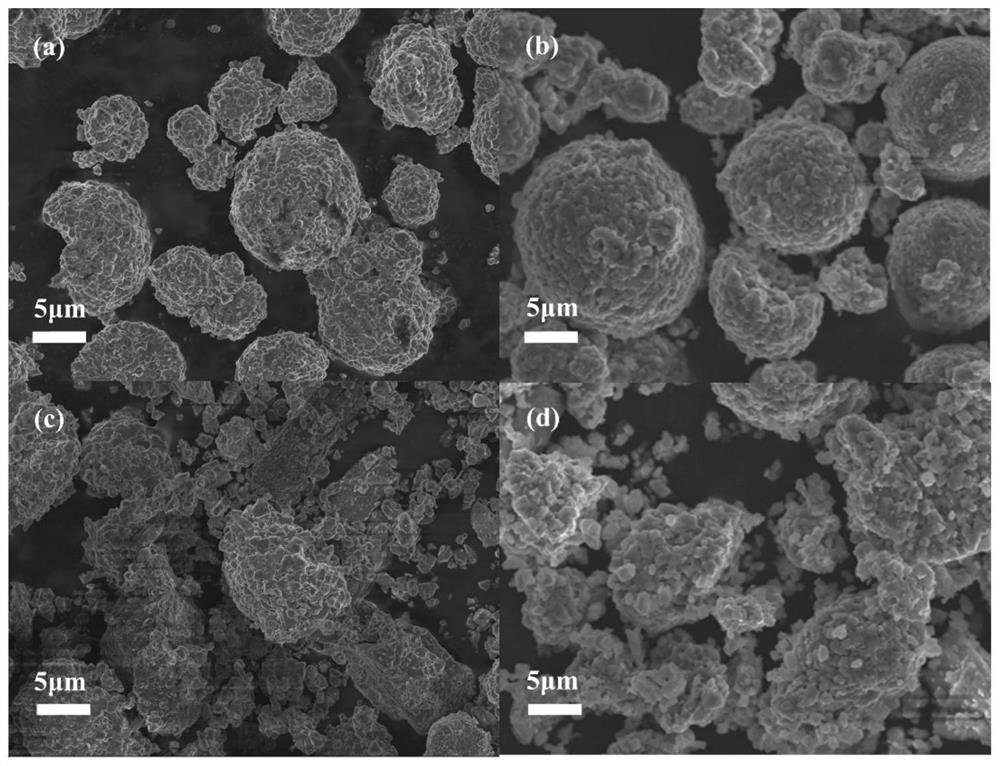

[0034] The X-ray diffraction pattern of the cathode material obtained in this embodiment is as follows figure 1 As shown, the main diffraction peaks are consistent with the diffraction peaks of high-nickel ternary cathode materials. After vanadium oxide compounding, the diffraction peaks did not move significant...

Embodiment 2

[0036] This embodiment provides a method for preparing a vanadium oxide composite high-nickel ternary positive electrode material, comprising the following steps:

[0037] (1) 1g of high-nickel ternary cathode material LiNi 0.85 co 0.1 mn 0.05 o 2 Mix evenly with 0.1 g of ammonium metavanadate, and thoroughly mix for 1 hour by ball milling, wherein the rotational speed of the ball mill is 400 rpm.

[0038] (2) Then put the ball-milled material into a tube furnace, heat up to 500°C for 4 hours in an oxygen atmosphere, and sinter at a rate of 5°C / min to obtain a high-nickel ternary cathode material for a lithium-ion battery composited with vanadium oxide. Its SEM such as figure 2 (d) shown. .

[0039] The processes of preparing electrodes and assembling batteries are the same as in Example 1. With a current density of 200mAg -1 When charging and discharging, the first discharge specific capacity can reach 138.7mAhg -1 , after 50 cycles, the discharge specific capacity ...

Embodiment 3

[0041] This embodiment provides a method for preparing a vanadium oxide composite high-nickel ternary positive electrode material, comprising the following steps:

[0042] (1) 1g of high-nickel ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Mix evenly with 0.05 g of ammonium metavanadate, and mix well by ball milling for 1 hour, wherein the rotational speed of the ball mill is 400 rpm.

[0043] (2) Then put the ball-milled material into a tube furnace, heat up to 400° C. for sintering for 6 hours in an oxygen atmosphere, and the heating rate is 5° C. / min to obtain a vanadium oxide composite lithium-ion battery high-nickel ternary positive electrode material.

[0044] The processes of preparing electrodes and assembling batteries are the same as in Example 1. With a current density of 200mAg -1 When charging and discharging, the first discharge specific capacity can reach 110.4mAhg -1 , after 50 cycles, the discharge specific capacity is still 72.7mAhg -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com