DGT adsorption film as well as preparation method and application thereof

An adsorption film and film forming technology, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of large sample volume and affecting the accuracy of results, etc., to reduce adsorption and effectively While the effect of accurate determination, high binding rate and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

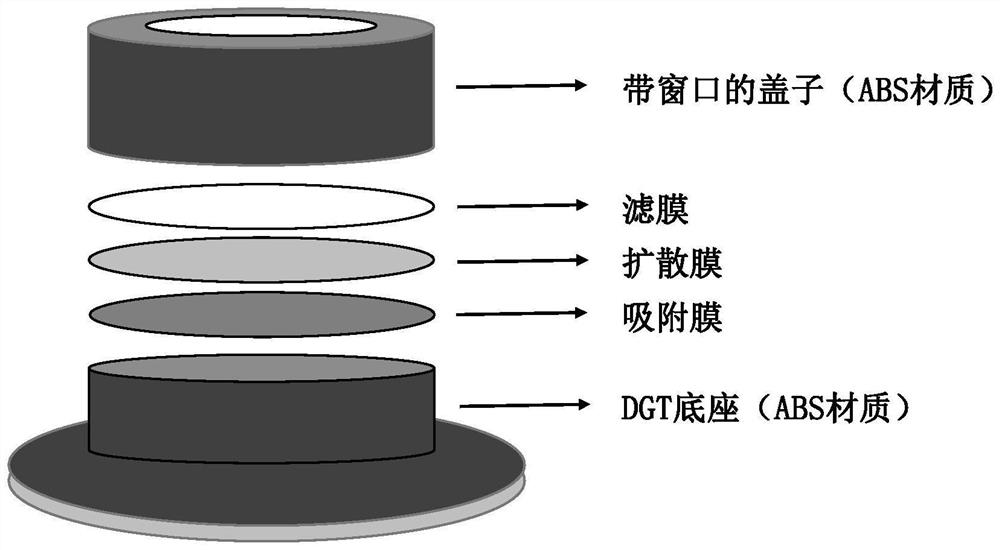

[0079] The adsorption film in the DGT device described in this example is made from PEP-2 resin particles (40-60 μm), and its preparation method includes the following steps:

[0080] (1) Activation of PEP-2 resin material

[0081] Methanol activation: add 30mL of methanol solvent to 20g of PEP-2 resin particles, shake up and down to make the methanol fully contact with the resin particles, then centrifuge at 3500r / min for 10 minutes, remove the supernatant, repeat the above steps twice to obtain sedimentation solid.

[0082]Cleaning with ultrapure water: add a certain volume of ultrapure water to the obtained deposited solid, shake it up and down so that the ultrapure water fully contacts the activated resin particles, then centrifuge at 3500r / min for 10 minutes, remove the supernatant, and repeat the above steps A precipitated solid was obtained after 3 steps.

[0083] (2) Preparation of PEP-2 adsorption membrane: Mix agar powder, activated PEP-2 resin and ultrapure water ...

Embodiment 2

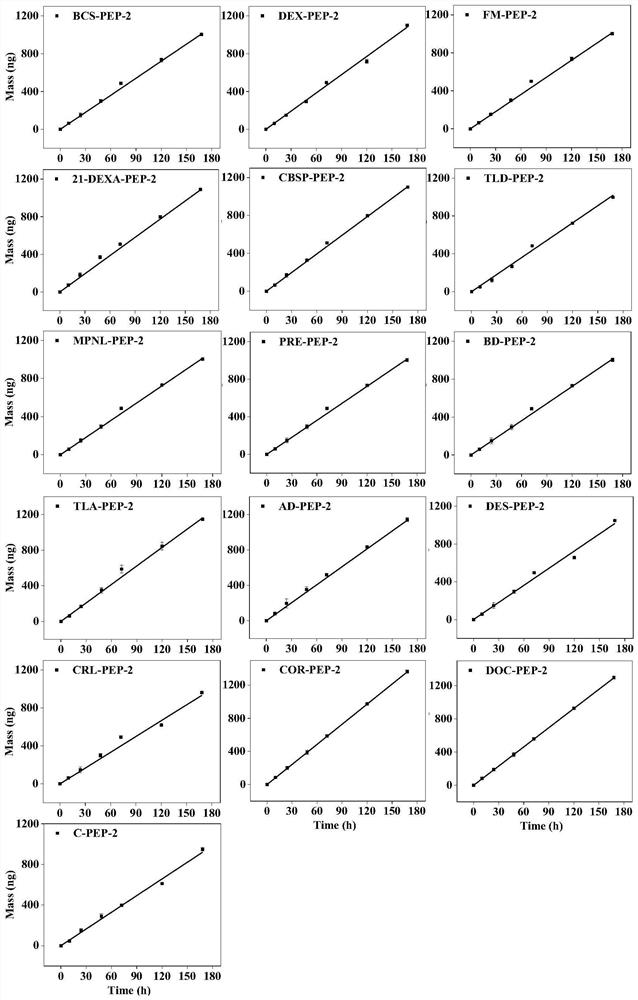

[0089] In this example, the PEP-2 adsorption membrane prepared in Example 1, the agarose diffusion membrane and the polytetrafluoroethylene (PTFE) filter membrane were assembled into a DGT device to measure glucocorticoid compounds in water.

[0090] In this embodiment, the DGT device is used to monitor the glucocorticoid compounds in the water body in situ, and the specific monitoring steps are as follows:

[0091] (1) Placement of the DGT device: place the DGT device assembled in step (1) in an aqueous solution containing a certain concentration of glucocorticoid compounds, keep the aqueous solution in a fully stirred state during the DGT placement process, and record the placement process of the DGT device The temperature of the aqueous solution and the DGT storage time.

[0092] (2) Recovery and elution of the adsorption film: take out the placed DGT device, rinse the surface with ultrapure water, then use a crowbar to pry open the device, take out the adsorption film and ...

Embodiment 3

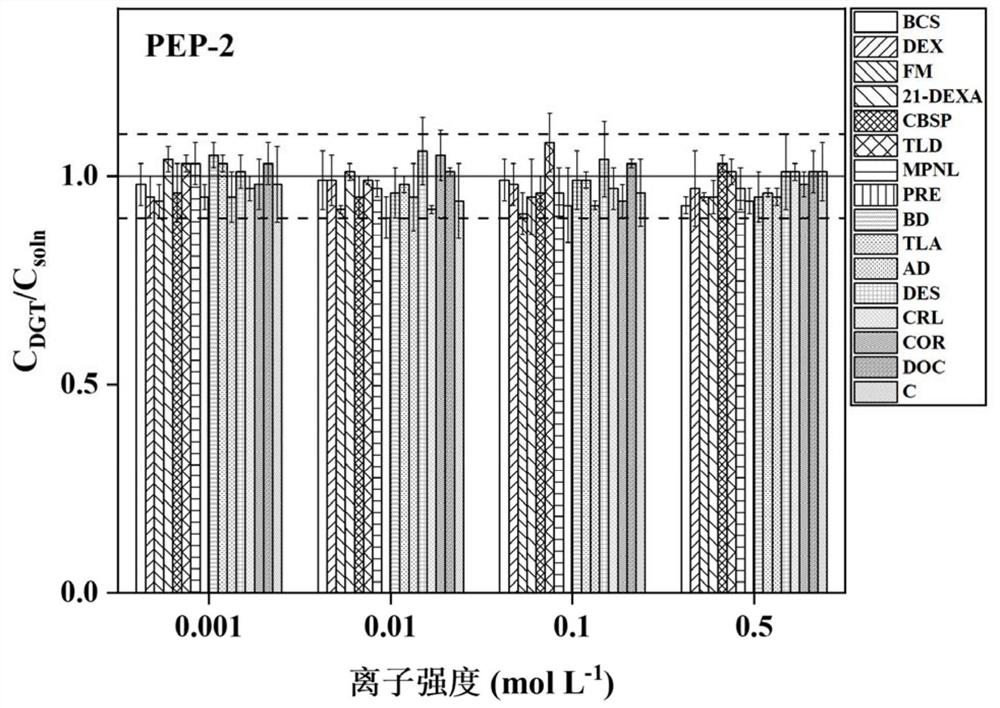

[0108] This example is basically the same as Example 2, except that the difference is that in this example, under the conditions of monitoring different ionic strengths, DGT technology is used to measure the influence of various glucocorticoid compounds in the water body, wherein the glucocorticoids in the water body to be tested The concentration of the compound is 10 μg / L, and the ionic strength (calculated as NaCl) of the aqueous solution to be tested is respectively: 0, 1, 10, 100, 500 mmol / L.

[0109] image 3 It is the adsorption effect diagram of the DGT device for various glucocorticoid compounds under different ionic strengths in this embodiment. The results show that the glucocorticoid concentration C measured by the DGT calculated according to the formula is DGT and the concentration of glucocorticoid compounds in aqueous solution (C soln ) ratio ranged from 0.9 to 1.1, indicating that the ionic strength of water had no significant effect on the results of DGT dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com