Freeze-thaw resistant recycled concrete and preparation method thereof

A cyclic regeneration and freeze-thaw resistance technology, applied in the field of building materials, can solve the problems of poor freeze-thaw resistance of recycled concrete, restrict development and application, and large expansion pressure, so as to improve freeze-thaw resistance and promote hydration. , the effect of internal densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

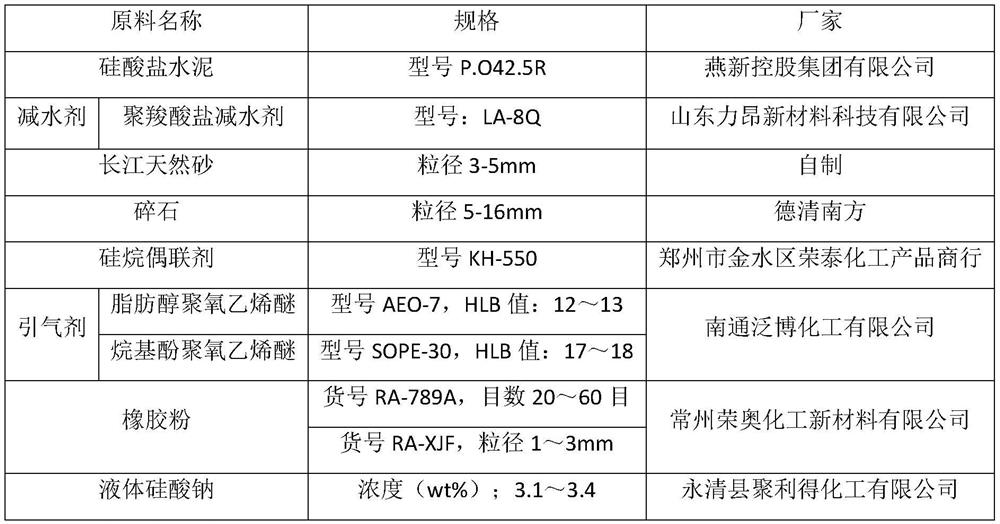

[0039] A silicone resin modified regenerated coarse aggregate and a silicone resin modified regenerated fine aggregate are prepared according to the following steps:

[0040] Put the waste cement blocks into the crusher and crush them to aggregates with a maximum particle size of no more than 31.5mm, and put the aggregates into the 5X series gravel shaping machine to produce machine-made sand equipment. The speed is 100m / s, and the reshaped recycled aggregate particles are rolled and screened once, and then screened twice, and the recycled aggregates with a particle size of 3-25mm are screened out, and the recycled aggregates are put into water and soaked for 48 hours. Take out the recycled aggregate and dry it in the sun;

[0041] Weigh 1kg of silane coupling agent KH-550 and 99kg of water, stir and blend, configure a silicone resin emulsion with a concentration of 1wt%, add 100kg of silicone resin emulsion to 200kg of recycled aggregate, and stir at a speed of 600rpm After ...

preparation example 2-3

[0043] A silicone resin-modified regenerated coarse aggregate and a silicone resin-modified regenerated fine aggregate differ from Preparation Example 1 in that the concentration of the silicone resin emulsion is different, and the specific concentrations are shown in Table 2 below.

[0044] Table 2. Concentrations of Silicone Resin Emulsions

[0045] Preparation example Silane coupling agent KH-550 / kg water / kg Silicone resin emulsion concentration / wt% Preparation Example 1 1 99 1 Preparation example 2 4 96 4 Preparation example 3 2 98 2

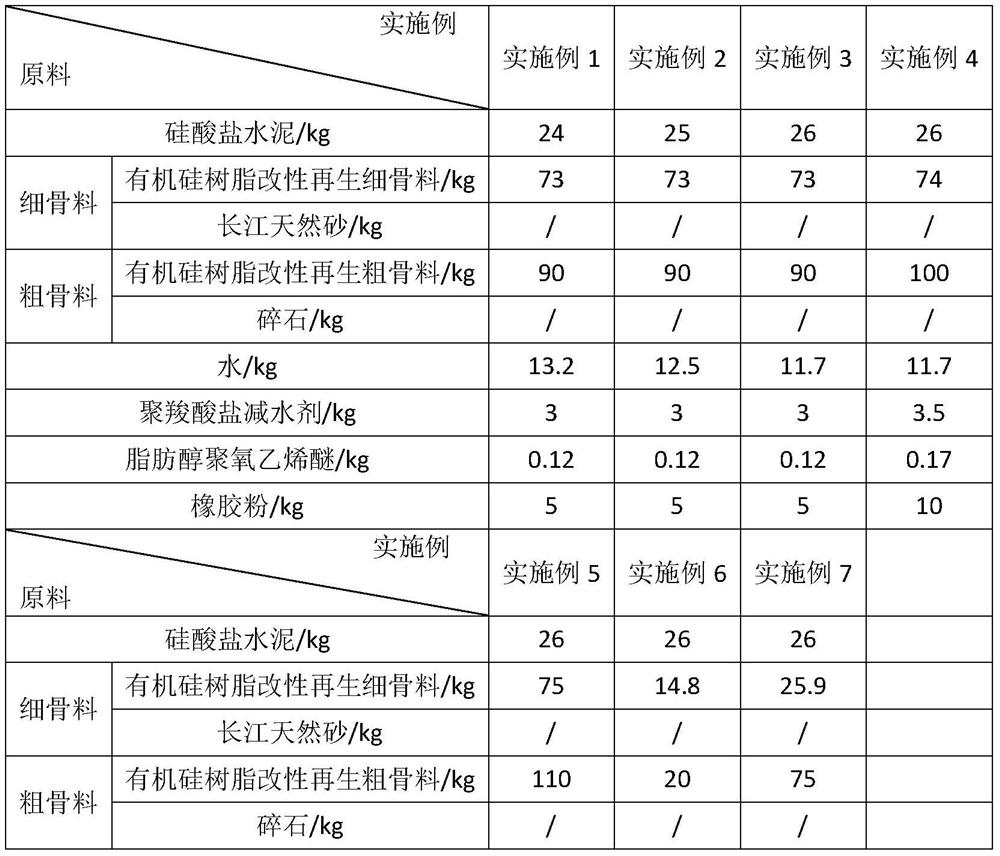

Embodiment 1

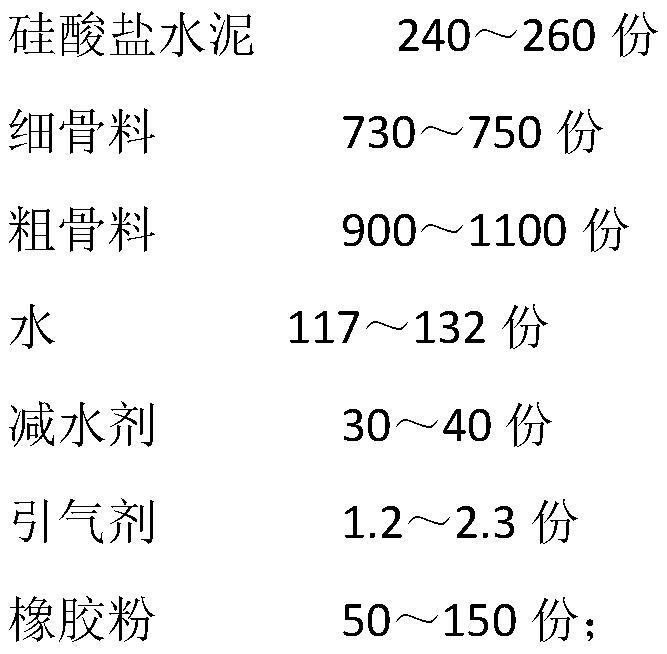

[0047]Embodiments 1-7 all provide a freeze-thaw cycle-resistant recycled concrete, which will be described below by taking Embodiment 1 as an example.

[0048] A kind of anti-freeze-thaw cycle recycled concrete provided in embodiment 1, its preparation steps are:

[0049] Take by weighing 24kg Portland cement, 73kg by the organosilicon resin modified regeneration fine aggregate that preparation example 3 makes, 90kg by the organosilicon resin modification regeneration coarse aggregate that preparation example 3 makes, 13.2kg water, 3kg poly Carboxylate superplasticizer LA-8Q, 0.12kg fatty alcohol polyoxyethylene ether AEO-7 and 0.5kg rubber powder RA-789A (mesh 20-60 mesh);

[0050] Put Portland cement, organosilicon resin modified regenerated fine aggregate, organosilicon resin modified regenerated coarse aggregate, polycarboxylate superplasticizer and rubber powder into the mixer, and stir and blend at a speed of 600rpm for 5min. After the stirring is completed, water and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com