Compound microbial agent as well as preparation method and application thereof

A compound microbial agent and microbial agent technology, applied in the field of biological control, can solve the problems of chemical pesticide residues, pathogenic bacteria resistance, etc., and achieve the effects of simple preparation, strong adaptability, and prolonging the effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

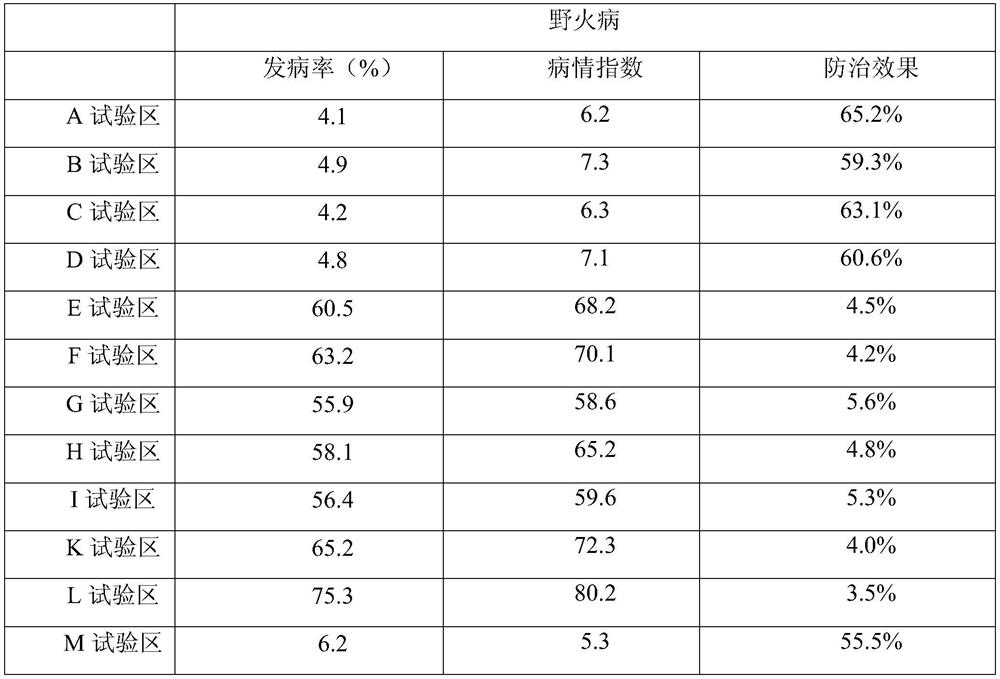

Examples

Embodiment 1

[0022] A composite microbial agent, including microbial agent and protective agent; said microbial agent contains the following components: 0.5×10 9 cfu / g Paenibacillus polymyxa, 0.8×10 9 cfu / g Bacillus amyloliquefaciens (Bacillus amyloliquefaciens), 0.6×10 9 cfu / g Bifidobacterium bifidum, 0.7×10 9 cfu / g Paecilomyces fumosa-roseus (Wize) Brown et Smith), 0.8×10 9 cfu / g Beauveria bassiana (Balsamo) Vuillemin and 0.9×10 9 cfu / g Lactobacillus helveticus (Lactobacillus helveticus); the protective agent comprises the following components by weight: 60 parts of corn flour, 5 parts of brown sugar, 0.5 part of ammonium sulfate, 0.4 part of potassium dihydrogen phosphate and 0.5 part of sulfuric acid heptahydrate Magnesium; the particle size of corn flour is 1.5mm; the mass ratio of microbial agent and protective agent in the composite microbial agent is 5:20.

[0023] A method for preparing said composite microbial bacterial agent, comprising the following steps:

[0024] (1) Str...

Embodiment 2

[0029] A composite microbial agent, including microbial agent and protective agent; said microbial agent comprises the following components: 0.9×10 9 cfu / g Paenibacillus polymyxa, 01.2×10 9cfu / g Bacillus amyloliquefaciens, 1.0×10 9 cfu / g Bifidobacterium bifidum, 1.1×10 9 cfu / g Paecilomyces fumosa-roseus (Wize) Brown et Smith), 1.2×10 9 cfu / g Beauveria bassiana (Balsamo) Vuillemin and 1.3×10 9 cfu / g Lactobacillus helveticus (Lactobacillus helveticus); the protective agent comprises the following components in parts by weight: 80 parts of corn flour, 8 parts of brown sugar, 0.8 part of ammonium sulfate, 0.6 part of potassium dihydrogen phosphate and 0.7 part of sulfuric acid heptahydrate Magnesium; the particle size of corn flour is 3mm; the mass ratio of microbial agent and protective agent in the composite microbial agent is 8:30.

[0030] A method for preparing said composite microbial bacterial agent, comprising the following steps:

[0031] (1) Strain activation: Paeni...

Embodiment 3

[0036] A composite microbial agent, including microbial agent and protective agent; said microbial agent contains the following components: 0.6×10 9 cfu / g Paenibacillus polymyxa, 1.0×10 9 cfu / g Bacillus amyloliquefaciens (Bacillus amyloliquefaciens), 0.8×10 9 cfu / g Bifidobacterium bifidum, 0.8×10 9 cfu / g Paecilomyces fumosa-roseus (Wize) Brown et Smith), 1.0×10 9 cfu / g Beauveria bassiana (Balsamo) Vuillemin and 1.1 x 10 9 cfu / g Lactobacillus helveticus (Lactobacillus helveticus); the protective agent comprises the following components in parts by weight: 70 parts of corn flour, 7 parts of brown sugar, 0.7 part of ammonium sulfate, 0.5 part of potassium dihydrogen phosphate and 0.6 part of sulfuric acid heptahydrate Magnesium; the particle size of corn flour is 2mm; the mass ratio of microbial inoculant and protective agent in the composite microbial inoculum is 6:25.

[0037] A method for preparing said composite microbial bacterial agent, comprising the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com