Preparation method of Cu3V2O8 nano bead string rich in oxygen vacancy defects

A technology of oxygen vacancies and defects, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of copper vanadate introducing oxygen vacancies, etc., and achieve the effect of easy industrial mass production, simple equipment and instruments, and industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Disperse the polypyrrole-coated cuprous oxide nanowires in deionized water, and magnetically stir to form a suspension A with a concentration of 0.00125 g / mL;

[0023] 2) adding polypyrrole-coated cuprous oxide nanowire mass 0.5 times the analytically pure ammonium metavanadate powder to the suspension A to obtain a mixed suspension B;

[0024] 3) Mix the β-cyclodextrin solution with a concentration of 0.05g / mL and the suspension B at a volume ratio of 2:10 evenly, seal the seal with a plastic wrap, and continuously stir and react at room temperature for 12 hours. The product was separated by filtration, washed with deionized water and dried at 60°C;

[0025] 4) Spread the product of step 3) on a porcelain boat, heat it from room temperature to 350°C at a heating rate of 2°C / min and keep it for 3 hours. After the reaction is completed, it is cooled with the furnace to obtain oxygen-rich defect Cu 3 V 2 o 8 Nano beads.

Embodiment 2

[0027] 1) Disperse the polypyrrole-coated cuprous oxide nanowires in deionized water, and magnetically stir to form a suspension A with a concentration of 0.00125 g / mL;

[0028] 2) adding polypyrrole-coated cuprous oxide nanowire mass 0.5 times the analytically pure ammonium metavanadate powder to the suspension A to obtain a mixed suspension B;

[0029] 3) Mix the β-cyclodextrin solution with a concentration of 0.05g / mL and the suspension B at a volume ratio of 1.8:10, seal the seal with plastic wrap, and react with continuous stirring at room temperature for 24 hours. The product was separated by filtration, washed with deionized water and dried at 60°C;

[0030] 4) Spread the product of step 3) on a porcelain boat, heat it from room temperature to 425°C at a heating rate of 2°C / min and keep it for 2 hours. After the reaction is completed, it is cooled in the furnace to obtain oxygen-rich defect Cu 3 V 2 o 8 Nano beads.

Embodiment 3

[0032] 1) Disperse the polypyrrole-coated cuprous oxide nanowires in deionized water, and magnetically stir to form a suspension A with a concentration of 0.00125 g / mL;

[0033] 2) Adding polypyrrole-coated cuprous oxide nanowires with 0.8 times the analytically pure ammonium metavanadate powder to the suspension A to obtain a mixed suspension B;

[0034]3) Mix the β-cyclodextrin solution with a concentration of 0.05g / mL and the suspension B at a volume ratio of 1.2:10, seal the seal with a plastic wrap, and react with continuous stirring at room temperature for 24 hours. The product was separated by filtration, washed with deionized water and dried at 60°C;

[0035] 4) Spread the product of step 3) on a porcelain boat, heat it from room temperature to 425°C at a heating rate of 5°C / min and keep it for 2 hours. After the reaction is completed, it is cooled in the furnace to obtain oxygen-rich defect Cu 3 V 2 o 8 Nano beads.

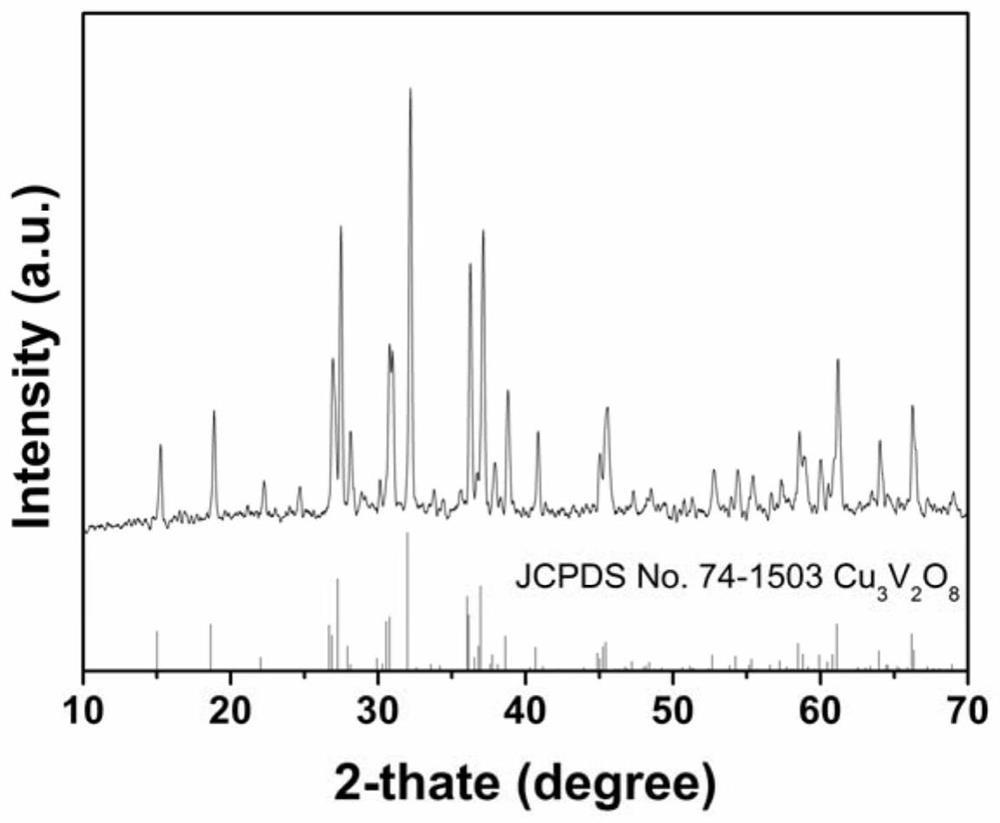

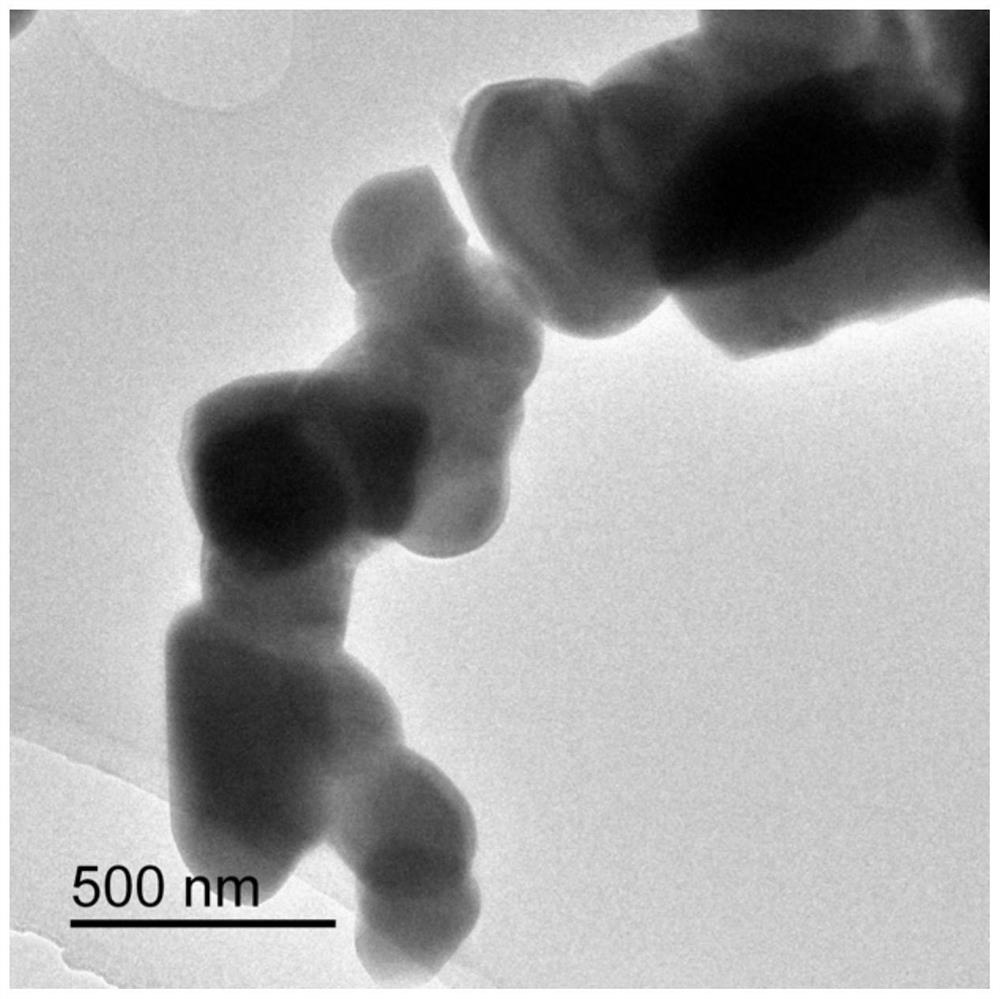

[0036] From figure 1 It can be seen that the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com